PDFWAC 296-24-68211

Acetylene generators.

(1) Approval and marking.

(a) Generators must be of approved construction and you must plainly mark them with the maximum rate of acetylene in cubic feet per hour for which they are designed; the weight and size of carbide necessary for a single charge; the manufacturer's name and address; and the name or number of the type of generator.

(b) Carbide must be of the size marked on the generator nameplate.

(2) Rating and pressure limitations.

(a) The total hourly output of a generator must not exceed the rate for which it is approved and marked. Unless specifically approved for higher ratings, carbide-feed generators must be rated at 1 cubic foot per hour per pound of carbide required for a single complete charge.

(b) You must regularly operate relief valves to ensure proper functioning. You must set relief valves for generating chambers to open at a pressure not in excess of 15 p.s.i.g. You must set relief valves for hydraulic back pressure valves to open at a pressure not in excess of 20 p.s.i.g.

(c) You must not use nonautomatic generators for generating acetylene at pressures exceeding 1 p.s.i.g., and all water overflows must be visible.

(3) Location. The space around the generator be ample for free, unobstructed operation and maintenance and permit ready adjustment and charging.

(4) Stationary acetylene generators (automatic and nonautomatic).

(a) You must arrange the foundation so that the generator will be level and so that no excessive strain will be placed on the generator or its connections. You must ground acetylene generators.

(b) You must place generators where water will not freeze. The use of common salt (sodium chloride) or other corrosive chemicals for protection against freezing is not permitted. (For heating systems see WAC 296-24-68211 (6)(k).)

(c) Except when generators are prepared in accordance with WAC 296-24-68211 (7)(i), you must prohibit sources of ignition in outside generator houses or inside generator rooms.

(d) You must not supply water through a continuous connection to the generator except when the generator is provided with an adequate open overflow or automatic water shutoff which will effectively prevent overfilling of the generator. Where a noncontinuous connection is used, the supply line must terminate at a point not less than 2 inches above the regularly provided opening for filling so that the water can be observed as it enters the generator.

(e) Unless otherwise specifically approved, generators must not be fitted with continuous drain connections leading to sewers, but must discharge through an open connection into a suitably vented outdoor receptacle or residue pit which may have such connections. An open connection for the sludge drawoff is desirable to enable the generator operator to observe leakage of generating water from the drain valve or sludge cock.

(f) You must provide each generator with a vent pipe of Schedule 40 galvanized iron or steel, except that outside of buildings, vent pipes larger than 4 inches in diameter may be not less than 14 gage galvanized tubing or sheet steel.

(g) You must rigidly install escape or relief pipe without traps and so that any condensation will drain back to the generator.

(h) You must carry the escape or relief pipe full size to a suitable point outside the building. It must terminate in a hood or bend located at least 12 feet above the ground, preferably above the roof, and as far away as practicable from windows or other openings into buildings and as far away as practicable from sources of ignition such as flues or chimneys and tracks used by locomotives. Generating chamber relief pipes must not be inter-connected but must be separately led to the outside air. The hood or bend must be so constructed that it will not be obstructed by rain, snow, ice, insects, or birds. The outlet must be at least 3 feet from combustible construction.

(i) Gas holders must be constructed on the gasometer principle, the bell being suitably guided. The gas bell must move freely without tendency to bind and must have a clearance of at least 2 inches from the shell.

(j) The gas holder may be located in the generator room, in a separate room or out of doors. In order to prevent collapse of the gas bell or infiltration of air due to a vacuum caused by the compressor or booster pump or cooling of the gas, a compressor or booster cutoff must be provided at a point 12 inches or more above the landing point of the bell. When the gas holder is located indoors, the room must be ventilated in accordance with WAC 296-24-68211 (6)(j) and heated and lighted in accordance with WAC 296-24-68211 (6)(k) and (1).

(k) When the gas holder is not located within a heated building, you must protect gas holder seals against freezing.

(l) You must provide means to stop the generator-feeding mechanism before the gas holder reaches the upper limit of its travel.

(m) When the gas holder is connected to only one generator, the gas capacity of the holder must be not less than 1/3 of the hourly rating of the generator.

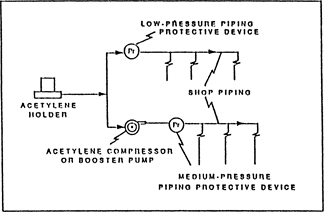

(n) If acetylene is used from the gas holder without increase in pressure at some points but with increase in pressure by a compressor or booster pump at other points, you must install approved piping protective devices in each supply line. You must locate the low-pressure protective device between the gas holder and the shop piping, and you must locate the medium-pressure protective device between the compressor or booster pump and the shop piping (see Figure Q-4). Approved protective equipment (designated PF) is used to prevent: Backflow of oxygen into the fuel-gas supply system; passage of a flashback into the fuel-gas supply system; and excessive back pressure of oxygen in the fuel-gas supply system. The three functions of the protective equipment may be combined in one device or may be provided by separate devices.

|

Figure Q-4 |

(o) The compressor or booster system must be of an approved type.

(p) Wiring and electrical equipment in compressor or booster pump rooms or enclosures must conform to the provisions of chapter 296-24 WAC Part L for Class I, Division 2 locations.

(q) You must locate compressors and booster pump equipment in well-ventilated areas away from open flames, electrical or mechanical sparks, or other ignition sources.

(r) You must provide compressor or booster pumps with pressure relief valves which will relieve pressure exceeding 15 p.s.i.g. to a safe outdoor location as provided in WAC 296-24-68211 (2)(b), or by returning the gas to the inlet side or to the gas supply source.

(s) You must provide compressor or booster pump discharge outlets with approved protective equipment. (See WAC 296-24-68211 (4)(e).)

(5) Portable acetylene generators.

(a) All portable generators must be of a type approved for portable use.

(b) You must not use portable generators within 10 feet of combustible material other than the floor.

(c) You must not use portable generators in rooms of total volume less than 35 times the total gas-generating capacity per charge of all generators in the room. You must not use generators in rooms having a ceiling height of less than 10 feet. (To obtain the gas-generating capacity in cubic feet per charge, multiply the pounds of carbide per charge by 4.5.)

(d) You must protect portable generators against freezing. The use of salt or other corrosive chemical to prevent freezing is prohibited.

(e) You must clean and recharge generators and the air mixture blown off outside buildings.

(f) When charged with carbide, you must not move portable generators by crane or derrick.

(g) When not in use, you must not store portable generators in rooms in which open flames are used unless the generators contain no carbide and have been thoroughly purged of acetylene. Storage rooms must be well ventilated.

(h) When portable acetylene generators are to be transported and operated on vehicles, you must securely anchor them to the vehicles. If transported by truck, you must turn off the motor during charging, cleaning, and generating periods.

(i) You must locate portable generators at a safe distance from the welding position so that they will not be exposed to sparks, slag, or misdirection of the torch flame or overheating from hot materials or processes.

(6) Outside generator houses and inside generator rooms for stationary acetylene generators.

(a) You must not locate any opening in any outside generator house within 5 feet of any opening in another building.

(b) Walls, floors and roofs of outside generator houses must be of noncombustible construction.

(c) When a part of the generator house is to be used for the storage or manifolding of oxygen cylinders, you must separate the space to be so occupied from the generator carbide storage section by partition walls continuous from floor to roof or ceiling, of the type of construction stated in WAC 296-24-68211 (6)(h). Such separation walls must be without openings and must be joined to the floor, other walls and ceiling or roof in a manner to effect a permanent gas-tight joint.

(d) You must locate exit doors so as to be readily accessible in case of emergency.

(e) You must provide explosion venting for outside generator houses and inside generator rooms in exterior walls or roofs. The venting areas must be equal to not less than 1 square foot per 50 cubic feet of room volume and may consist of any one or any combination of the following: Walls of light, noncombustible material preferably single-thickness, single-strength glass; lightly fastened hatch covers; lightly fastened swinging doors in exterior walls opening outward; lightly fastened walls or roof designed to relieve at a maximum pressure of 25 pounds per square foot.

(f) You must restrict the installation of acetylene generators within buildings to buildings not exceeding one story in height: Provided, however, That this will not be construed as prohibiting such installations on the roof or top floor of a building exceeding such height.

(g) You must enclose generators installed inside buildings in a separate room of ample size.

(h) The walls, partitions, floors, and ceilings of inside generator rooms must be of noncombustible construction having a fire-resistance rating of at least one hour. The walls or partitions must be continuous from floor to ceiling and must be securely anchored. At least one wall of the room must be an exterior wall.

(i) You must protect openings from an inside generator room to other parts of the building by a swinging type, self-closing fire door for a Class B opening and having a rating of at least one hour. Windows in partitions must be wired glass and approved metal frames with fixed sash. Installation must be in accordance with the Standard for the Installation of Fire Doors and Windows, NFPA 80-1970.

(j) Inside generator rooms or outside generator houses must be well ventilated with vents located at floor and ceiling levels.

(k) Heating must be by steam, hot water, enclosed electrically heated elements or other indirect means. You must prohibit heating by flames or fires in outside generator houses or inside generator rooms, or in any enclosure communicating with them.

(l) Generator houses or rooms must have natural light during daylight hours. Where artificial lighting is necessary you must restrict it to electric lamps installed in a fixed position. Unless specifically approved for use in atmospheres containing acetylene, you must provide such lamps with enclosures of glass or other noncombustible material so designed and constructed as to prevent gas vapors from reaching the lamp or socket and to resist breakage. You must use rigid conduit with threaded connections.

(m) Lamps installed outside of wired-glass panels set in gas-tight frames in the exterior walls or roof of the generator house or room are acceptable.

(n) You must locate electric switches, telephones, and all other electrical apparatus which may cause a spark, unless specifically approved for use inside acetylene generator rooms, outside the generator house or in a room or space separated from the generator room by a gas-tight partition, except that where the generator system is designed so that no carbide fill opening or other part of the generator is open to the generator house or room during the operation of the generator, and so that residue is carried in closed piping from the residue discharge valve to a point outside the generator house or room, electrical equipment in the generator house or room must conform to the provisions of the chapter 296-24 WAC Part L for Class I, Division 2 locations.

(7) Maintenance and operation.

(a) You must not permit unauthorized persons in outside generator houses or inside generator rooms.

(b) You must post operating instructions in a conspicuous place near the generator or kept in a suitable place available for ready reference.

(c) When recharging generators you must follow the order of operations specified in the instructions supplied by the manufacturer.

(d) In the case of batch-type generators, when the charge of carbide is exhausted and before additional carbide is added, you must always flush out the generating chamber with water, renewing the water supply in accordance with the instruction card furnished by the manufacturer.

(e) You must not discharge the water-carbide residue mixture drained from the generator into sewer pipes or stored in areas near open flames. Clear water from residue settling pits may be discharged into sewer pipes.

(f) The carbide added each time the generator is recharged must be sufficient to refill the space provided for carbide without ramming the charge. You must not use steel or other ferrous tools in distributing the charge.

(g) You must keep generator water chambers filled to proper level at all times except while draining during the recharging operation.

(h) Whenever repairs are to be made or the generator is to be charged or carbide is to be removed, you must fill the water chamber to the proper level.

(i) Previous to making repairs involving welding, soldering, or other hot work or other operations which produce a source of ignition, you must completely remove the carbide charge and feed mechanism. You must expel all acetylene by completely flooding the generator shell with water and you must disconnect the generator from the piping system. You must keep the generator filled with water, if possible, or position it to hold as much water as possible.

(j) You must not make hot repairs in a room where there are other generators unless all the generators and piping have been purged of acetylene. Hot repairs should preferably be made out of doors.

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. WSR 15-24-100, § 296-24-68211, filed 12/1/15, effective 1/5/16. Statutory Authority: Chapter 49.17 RCW. WSR 91-24-017 (Order 91-07), § 296-24-68211, filed 11/22/91, effective 12/24/91; Order 73-5, § 296-24-68211, filed 5/9/73 and Order 73-4, § 296-24-68211, filed 5/7/73.]