PDFWAC 296-155-56115

Compression hardware.

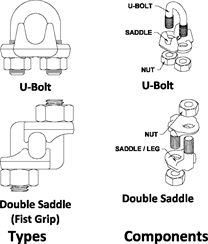

(1) Wire rope clips. Follow these assembly requirements for wire rope clips:

(a) Before installing a wire rope clip on plastic coated or plastic impregnated wire rope, you must consult the wire rope clip manufacturer, wire rope manufacturer or a qualified person.

(b) For U-bolt clips used to create end terminations, you must place the saddle on the live end of the wire rope, with the U-bolt on the dead end side. (See Figure 35, Wire Rope Clips.)

(c) You must test the assembly by loading the connection to at least the expected working load. After unloading, retighten the wire rope clips to the torque recommended by the manufacturer or a qualified person.

(d) Follow the manufacturer's recommendations for the minimum number of clips, spacing and turn-back measurements, and to the recommended torque values. In the absence of the manufacturer's recommendations follow Table 15.

|

Figure 35 Wire Rope Clips |

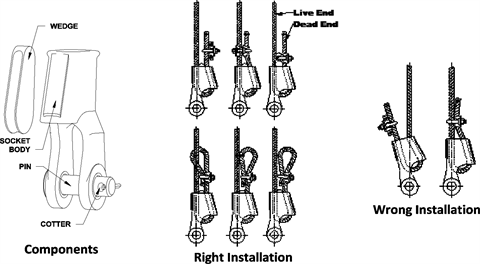

(2) Wedge sockets. Follow these assembly requirements for wedge sockets:

(a) You must assemble wedge sockets as recommended by the manufacturer or a qualified person.

(b) Before installing a wedge socket on plastic coated or plastic impregnated wire rope you must consult the wedge socket manufacturer, wire rope manufacturer or a qualified person.

(c) The assembler must match the proper wedge with the socket for the wire rope to be installed. You must not interchange wedges between different manufacturers' sockets or models.

(d) The live end of the wire rope in the wedge socket cavity must be in alignment with the socket's pin. (See Figure 36, Wedge Sockets.)

(e) The length of the dead end tail of the wire rope must be as required by the manufacturer or a qualified person.

(f) You must secure the tail of the dead end of the wire rope extending beyond the wedge socket as recommended by the wedge socket manufacturer or a qualified person.

(g) You must not secure the dead end of the wire rope to the live end of the wire rope in a way that restricts the movement of the live end. (See Figure 36.)

(h) After assembly you must load the connection to fully seat the wedge before use.

|

Figure 36 Wedge Sockets |

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 16-09-085, § 296-155-56115, filed 4/19/16, effective 5/20/16. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.440, 49.17.060, and 29 C.F.R. 1926, Subpart CC. WSR 12-01-086, § 296-155-56115, filed 12/20/11, effective 2/1/12.]