Chapter 296-307 WAC

Last Update: 8/20/24SAFETY STANDARDS FOR AGRICULTURE

WAC Sections

FIELD OPERATIONS AND GENERAL REQUIREMENTS Part A General and Educational Requirements | ||||

| HTMLPDF | 296-307-003 | Navigating this chapter. | ||

| HTMLPDF | 296-307-006 | Scope. | ||

| HTMLPDF | 296-307-009 | Definitions that apply to this chapter. | ||

| HTMLPDF | 296-307-012 | Equipment approved by a nonstate organization. | ||

| HTMLPDF | 296-307-018 | Employer responsibilities. | ||

| HTMLPDF | 296-307-021 | Employee responsibilities. | ||

| HTMLPDF | 296-307-024 | Applying for a variance. | ||

Part B Accident Prevention Program; First-aid Requirements; Safe Place Standard | ||||

| HTMLPDF | 296-307-030 | Required elements of an accident prevention program. | ||

| HTMLPDF | 296-307-033 | Requirements for how often safety meetings must be held. | ||

| HTMLPDF | 296-307-036 | Items to go on the safety bulletin board. | ||

| HTMLPDF | 296-307-039 | First-aid rule summary. | ||

| HTMLPDF | 296-307-03905 | Make sure that first-aid trained personnel are available to provide quick and effective first aid. | ||

| HTMLPDF | 296-307-03920 | Make sure appropriate first-aid supplies are readily available. | ||

| HTMLPDF | 296-307-03930 | Make sure emergency washing facilities are functional and readily accessible. | ||

| HTMLPDF | 296-307-03935 | Inspect and activate emergency washing facilities. | ||

| HTMLPDF | 296-307-03940 | Make sure supplemental flushing equipment provides sufficient water. | ||

| HTMLPDF | 296-307-03945 | Definitions. | ||

| HTMLPDF | 296-307-045 | Requirements for safe place standard. | ||

Part C Hand Tools | ||||

| HTMLPDF | 296-307-050 | Requirements that apply to hand tools. | ||

Part D Ladders, Bulk Storage, Pits, and Trenches | ||||

| HTMLPDF | 296-307-055 | Ladders. | ||

| HTMLPDF | 296-307-05501 | Ladder care and maintenance. | ||

| HTMLPDF | 296-307-05503 | Instructing employees on the use of ladders. | ||

| HTMLPDF | 296-307-05505 | Use of orchard ladders. | ||

| HTMLPDF | 296-307-05507 | Ladder requirements. | ||

| HTMLPDF | 296-307-060 | Requirements that apply to job-made ladders. | ||

| HTMLPDF | 296-307-061 | Requirements that apply to working around bins, bunkers, hoppers, tanks, pits, and trenches. | ||

Part E Vehicles and Farm Field Equipment | ||||

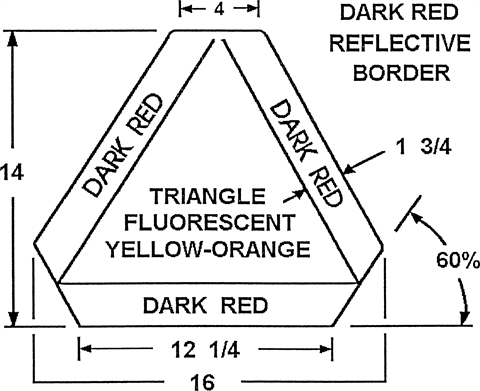

| HTMLPDF | 296-307-065 | Identification of slow-moving vehicles. | ||

| HTMLPDF | 296-307-070 | Motor vehicles. | ||

| HTMLPDF | 296-307-07001 | Motor vehicle maintenance. | ||

| HTMLPDF | 296-307-07003 | Motor vehicle operation. | ||

| HTMLPDF | 296-307-07005 | Qualifications to operate motor vehicle. | ||

| HTMLPDF | 296-307-07007 | Requirements that apply to motor vehicle brakes. | ||

| HTMLPDF | 296-307-07009 | Loading and unloading motor vehicles. | ||

| HTMLPDF | 296-307-07011 | Required safety equipment for motor vehicles. | ||

| HTMLPDF | 296-307-07013 | Rules that apply to vehicles used to transport employees. | ||

| HTMLPDF | 296-307-073 | Requirements that apply to changing and charging, and storage of batteries. | ||

| HTMLPDF | 296-307-076 | Guarding farm field equipment. | ||

Part F Rollover Protective Structures (ROPS) for Tractors | ||||

| HTMLPDF | 296-307-080 | Rollover protective structures (ROPS) for tractors. | ||

| HTMLPDF | 296-307-08003 | Agricultural tractors covered by this section. | ||

| HTMLPDF | 296-307-08006 | Definitions that apply to rollover protective structures (ROPS) for agricultural tractors. | ||

| HTMLPDF | 296-307-08009 | Requirements that apply to the testing and performance of ROPS used on agricultural tractors. | ||

| HTMLPDF | 296-307-08012 | Requirements that apply to seatbelts used with ROPS on agricultural tractors. | ||

| HTMLPDF | 296-307-08015 | ROPS requirements that apply to agricultural tractors. | ||

| HTMLPDF | 296-307-08018 | Required employee training that apply to ROPS used on agricultural tractors. | ||

| HTMLPDF | 296-307-08021 | Requirements that apply to ROPS used on agricultural tractors. | ||

| HTMLPDF | 296-307-085 | Requirements for ROPS to be provided for material handling equipment. | ||

| HTMLPDF | 296-307-090 | Requirements that apply to overhead protection for operators of agricultural and industrial tractors. | ||

Part G Field Sanitation | ||||

| HTMLPDF | 296-307-095 | Field sanitation. | ||

| HTMLPDF | 296-307-09503 | Scope. | ||

| HTMLPDF | 296-307-09506 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-09509 | Required field sanitation training. | ||

| HTMLPDF | 296-307-09512 | The employer must provide potable water sources. | ||

| HTMLPDF | 296-307-09515 | Handwashing facilities. | ||

| HTMLPDF | 296-307-09518 | Toilet facilities. | ||

Part G-1 | ||||

| HTMLPDF | 296-307-097 | Outdoor heat exposure. | ||

| HTMLPDF | 296-307-09710 | Scope and purpose. | ||

| HTMLPDF | 296-307-09720 | Definitions. | ||

| HTMLPDF | 296-307-09730 | Employer and employee responsibility. | ||

| HTMLPDF | 296-307-09735 | Access to shade. | ||

| HTMLPDF | 296-307-09740 | Drinking water. | ||

| HTMLPDF | 296-307-09745 | Acclimatization. | ||

| HTMLPDF | 296-307-09747 | High heat procedures. | ||

| HTMLPDF | 296-307-09750 | Responding to signs and symptoms of heat-related illness. | ||

| HTMLPDF | 296-307-09760 | Information and training. | ||

| HTMLPDF | 296-307-098 | Wildfire smoke. | ||

| HTMLPDF | 296-307-09805 | Purpose and scope. | ||

| HTMLPDF | 296-307-09810 | Definitions. | ||

| HTMLPDF | 296-307-09815 | Identification of harmful exposures. | ||

| HTMLPDF | 296-307-09820 | Hazard communication. | ||

| HTMLPDF | 296-307-09825 | Information and training. | ||

| HTMLPDF | 296-307-09830 | Exposure symptom response. | ||

| HTMLPDF | 296-307-09835 | Exposure controls. | ||

| HTMLPDF | 296-307-09840 | Respiratory protection. | ||

| HTMLPDF | 296-307-09845 | Measuring PM2.5 levels at the worksite. | ||

| HTMLPDF | 296-307-09850 | Appendix A: Protection from wildfire smoke information and training (mandatory). | ||

| HTMLPDF | 296-307-09860 | Appendix B: Calculating the Air Quality Index for PM2.5 (nonmandatory). | ||

Part H Personal Protective Equipment | ||||

| HTMLPDF | 296-307-100 | Personal protective equipment. | ||

| HTMLPDF | 296-307-10005 | Personal protective equipment. | ||

| HTMLPDF | 296-307-10010 | Requirements that apply to eye protection. | ||

| HTMLPDF | 296-307-10015 | Requirements for personal protective equipment. | ||

| HTMLPDF | 296-307-10020 | Preventing heat-related illnesses. | ||

| HTMLPDF | 296-307-10025 | Training for personal protective equipment. | ||

| HTMLPDF | 296-307-10030 | Voluntary use of personal protective equipment (PPE). | ||

Part I Worker Protection Standard | ||||

| HTMLPDF | 296-307-108 | General provisions. | ||

| HTMLPDF | 296-307-10805 | Federal worker protection standard—Washington state department of labor and industries. | ||

| HTMLPDF | 296-307-10810 | Scope and purpose—40 C.F.R., Sec. 170.301. | ||

| HTMLPDF | 296-307-10815 | Applicability—40 C.F.R., Sec. 170.303. | ||

| HTMLPDF | 296-307-10820 | Definitions—40 C.F.R., Sec. 170.305. | ||

| HTMLPDF | 296-307-10825 | Agricultural employer duties—40 C.F.R., Sec. 170.309. | ||

| HTMLPDF | 296-307-10830 | Display requirements for pesticide safety information and pesticide application and hazard information—40 C.F.R., Sec. 170.311. | ||

| HTMLPDF | 296-307-10835 | Commercial pesticide handler employer duties—40 C.F.R., Sec. 170.313. | ||

| HTMLPDF | 296-307-10840 | Prohibited actions—40 C.F.R., Sec. 170.315. | ||

| HTMLPDF | 296-307-10845 | Violations of this part—40 C.F.R., Sec. 170.317. | ||

Requirements for Protection of Agricultural Workers | ||||

| HTMLPDF | 296-307-109 | Requirements for protection of agricultural workers. | ||

| HTMLPDF | 296-307-10905 | Training requirements for workers—40 C.F.R., Sec. 170.401. | ||

| HTMLPDF | 296-307-10910 | Establishment-specific information for workers—40 C.F.R., Sec. 170.403. | ||

| HTMLPDF | 296-307-10915 | Entry restrictions associated with pesticide applications—40 C.F.R., Sec. 170.405. | ||

| HTMLPDF | 296-307-10920 | Worker entry restrictions after pesticide applications—40 C.F.R., Sec. 170.407. | ||

| HTMLPDF | 296-307-10925 | Oral and posted notification of worker entry restrictions—40 C.F.R., Sec. 170.409. | ||

| HTMLPDF | 296-307-10930 | Decontamination supplies for workers—40 C.F.R., Sec. 170.411. | ||

Requirements for the Protection of Agricultural Pesticide Handlers | ||||

| HTMLPDF | 296-307-112 | Requirements for protection of agricultural pesticide handlers. | ||

| HTMLPDF | 296-307-11205 | Training requirements for handlers—40 C.F.R., Sec. 170.501. | ||

| HTMLPDF | 296-307-11210 | Knowledge of labeling, application-specific, and establishment-specific information for handlers—40 C.F.R., Sec. 170.503. | ||

| HTMLPDF | 296-307-11215 | Requirements during applications to protect handlers, workers, and other persons—40 C.F.R., Sec. 170.505. | ||

| HTMLPDF | 296-307-11220 | Personal protective equipment—40 C.F.R., Sec. 170.507. | ||

| HTMLPDF | 296-307-11225 | Decontamination and eye flushing supplies for handlers—40 C.F.R., Sec. 170.509. | ||

Exemptions, Exceptions and Equivalency | ||||

| HTMLPDF | 296-307-114 | Exemptions, exceptions and equivalency. | ||

| HTMLPDF | 296-307-11405 | Exemptions—40 C.F.R., Sec. 170.601. | ||

| HTMLPDF | 296-307-11410 | Exceptions for entry by workers during restricted-entry intervals—40 C.F.R., Sec. 170.603. | ||

| HTMLPDF | 296-307-11415 | Agricultural employer responsibilities to protect workers entering treated areas during a restricted-entry interval—40 C.F.R., Sec. 170.605. | ||

| HTMLPDF | 296-307-11420 | Exceptions to personal protective equipment requirements specified on pesticide product labeling—40 C.F.R., Sec. 170.607. | ||

Part J Pesticides Recordkeeping | ||||

| HTMLPDF | 296-307-145 | Pesticides recordkeeping. | ||

| HTMLPDF | 296-307-14505 | Recordkeeping for pesticide applications. | ||

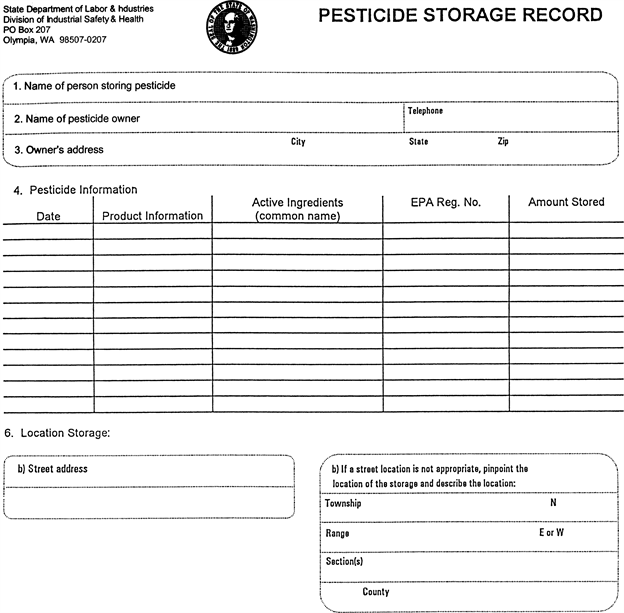

| HTMLPDF | 296-307-14510 | Sample pesticide storage record. | ||

Part J-1 Cholinesterase Monitoring | ||||

| HTMLPDF | 296-307-148 | Scope and summary. | ||

| HTMLPDF | 296-307-14805 | Maintain handling records for covered pesticides. | ||

| HTMLPDF | 296-307-14810 | Implement a medical monitoring program. | ||

| HTMLPDF | 296-307-14815 | Identify a physician or other licensed health care professional. | ||

| HTMLPDF | 296-307-14820 | Make cholinesterase testing available. | ||

| HTMLPDF | 296-307-14825 | Respond to depressed cholinesterase levels. | ||

| HTMLPDF | 296-307-14830 | Provide medical removal protection benefits. | ||

| HTMLPDF | 296-307-14835 | Maintain records. | ||

| HTMLPDF | 296-307-14840 | Provide training. | ||

| HTMLPDF | 296-307-14845 | Implementation plan. | ||

Part K Working Near Overhead Lines | ||||

| HTMLPDF | 296-307-150 | Employees working near overhead lines. | ||

| HTMLPDF | 296-307-15003 | Scope. | ||

| HTMLPDF | 296-307-15006 | Clearance and safeguards required to protect employees working near overhead lines. | ||

| HTMLPDF | 296-307-15009 | Signs an employer must post to warn employees working near overhead lines. | ||

| HTMLPDF | 296-307-15012 | The employer must notify the utility when employees are working near overhead lines. | ||

Part L Temporary Worker Housing (TWH) | ||||

| HTMLPDF | 296-307-161 | Temporary worker housing and cherry harvest camps. | ||

| HTMLPDF | 296-307-16101 | Purpose and applicability. | ||

| HTMLPDF | 296-307-16103 | Definitions. | ||

| HTMLPDF | 296-307-16104 | Technical assistance—Notice of violation. | ||

| HTMLPDF | 296-307-16115 | Maximum capacity for TWH occupants. | ||

| HTMLPDF | 296-307-16120 | Variance and procedure. | ||

| HTMLPDF | 296-307-16125 | Temporary worker housing sites and cherry harvest campsites. | ||

| HTMLPDF | 296-307-16127 | TWH management plan. | ||

| HTMLPDF | 296-307-16130 | Water supply. | ||

| HTMLPDF | 296-307-16135 | Sewage disposal. | ||

| HTMLPDF | 296-307-16140 | Electricity and lighting. | ||

| HTMLPDF | 296-307-16145 | Building requirements and maintenance. | ||

| HTMLPDF | 296-307-16146 | Ventilation. | ||

| HTMLPDF | 296-307-16147 | Tents. | ||

| HTMLPDF | 296-307-16149 | Carbon monoxide alarms, smoke detectors, and fire extinguishers. | ||

| HTMLPDF | 296-307-16150 | Laundry facilities. | ||

| HTMLPDF | 296-307-16155 | Handwashing and bathing facilities. | ||

| HTMLPDF | 296-307-16160 | Toilet facilities. | ||

| HTMLPDF | 296-307-16165 | Cooking and food-handling facilities. | ||

| HTMLPDF | 296-307-16170 | Cots, beds, bedding, and personal storage. | ||

| HTMLPDF | 296-307-16175 | First aid and safety. | ||

| HTMLPDF | 296-307-16180 | Refuse (waste) disposal. | ||

| HTMLPDF | 296-307-16185 | Insect and rodent control. | ||

| HTMLPDF | 296-307-16190 | Disease prevention and control. | ||

INDOOR OPERATIONS Part M Guarding Tools and Equipment; Farm Shops; Materials Handling | ||||

| HTMLPDF | 296-307-18005 | Guarding fan blades. | ||

| HTMLPDF | 296-307-18010 | Guarding constant-running drives. | ||

| HTMLPDF | 296-307-18015 | Training an employer must provide for employees who use agricultural equipment. | ||

| HTMLPDF | 296-307-18020 | Machine controls. | ||

| HTMLPDF | 296-307-18025 | Steam pipe guarding. | ||

| HTMLPDF | 296-307-185 | Guarding powered saws. | ||

| HTMLPDF | 296-307-18503 | Powered saws. | ||

| HTMLPDF | 296-307-18506 | Guarding band saws. | ||

| HTMLPDF | 296-307-18509 | Guarding radial arm saws. | ||

| HTMLPDF | 296-307-18512 | Guarding table saws. | ||

| HTMLPDF | 296-307-18515 | Guarding circular fuel-wood saws. | ||

| HTMLPDF | 296-307-190 | Guarding bench grinders, abrasive wheels, and portable grinders. | ||

| HTMLPDF | 296-307-19003 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-19006 | Guarding abrasive wheels. | ||

| HTMLPDF | 296-307-19009 | The use, mounting, and guarding rules for abrasive wheels. | ||

| HTMLPDF | 296-307-19012 | Flanges. | ||

| HTMLPDF | 296-307-19015 | Guarding vertical portable grinders. | ||

| HTMLPDF | 296-307-19018 | Guarding other portable grinders. | ||

| HTMLPDF | 296-307-195 | Grounding and "dead man" controls for hand-held portable power tools. | ||

| HTMLPDF | 296-307-200 | Compressed air. | ||

| HTMLPDF | 296-307-20005 | Compressed air for cleaning. | ||

| HTMLPDF | 296-307-20010 | Compressed air tools. | ||

| HTMLPDF | 296-307-205 | Guarding portable powered tools. | ||

| HTMLPDF | 296-307-20505 | Guarding portable powered tools. | ||

| HTMLPDF | 296-307-20510 | Switches and controls on portable powered tools. | ||

| HTMLPDF | 296-307-20515 | Pneumatic powered tools and hose. | ||

| HTMLPDF | 296-307-220 | Power lawnmowers. | ||

| HTMLPDF | 296-307-22003 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-22006 | Guarding power lawnmowers. | ||

| HTMLPDF | 296-307-22009 | Walk-behind and riding rotary mowers. | ||

| HTMLPDF | 296-307-22012 | Walk-behind rotary mowers. | ||

| HTMLPDF | 296-307-22015 | Riding rotary mowers. | ||

| HTMLPDF | 296-307-225 | Jacks. | ||

| HTMLPDF | 296-307-22503 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-22506 | The rated load must be marked on a jack. | ||

| HTMLPDF | 296-307-22509 | Operation and maintenance of jacks. | ||

| HTMLPDF | 296-307-230 | General requirements for materials handling and storage. | ||

| HTMLPDF | 296-307-232 | Conveyors. | ||

Part N Sanitation for Indoor Workplaces | ||||

| HTMLPDF | 296-307-240 | Sanitation for fixed, indoor workplaces. | ||

| HTMLPDF | 296-307-24001 | The employer must comply with state health regulations. | ||

| HTMLPDF | 296-307-24003 | Scope. | ||

| HTMLPDF | 296-307-24006 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-24009 | Housekeeping requirements that apply to fixed, indoor workplaces. | ||

| HTMLPDF | 296-307-24012 | Maintenance of potable water supply. | ||

| HTMLPDF | 296-307-24015 | Maintenance of nonpotable water supply. | ||

| HTMLPDF | 296-307-24018 | Toilet facilities. | ||

| HTMLPDF | 296-307-24021 | Employer provided washing facilities. | ||

| HTMLPDF | 296-307-24024 | Lavatories. | ||

| HTMLPDF | 296-307-24027 | Employer provided change rooms. | ||

| HTMLPDF | 296-307-24030 | Consumption of food and beverages in the workplace. | ||

| HTMLPDF | 296-307-24033 | Waste storage and removal. | ||

| HTMLPDF | 296-307-24036 | Employer vermin control programs. | ||

Part O Walking Working Surfaces; Fixed Industrial Stairs; Aerial Manlifts | ||||

| HTMLPDF | 296-307-250 | Walking working surfaces, elevated walkways, and platforms. | ||

| HTMLPDF | 296-307-25003 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-25006 | When railings may be omitted. | ||

| HTMLPDF | 296-307-25009 | Protection an employer must provide for openings. | ||

| HTMLPDF | 296-307-25012 | Protection an employer must provide for openings and holes. | ||

| HTMLPDF | 296-307-25015 | Protection an employer must provide for open-sided floors, platforms, and runways. | ||

| HTMLPDF | 296-307-25018 | Requirements that apply to stairway railings and guards. | ||

| HTMLPDF | 296-307-25021 | Standard railing construction. | ||

| HTMLPDF | 296-307-25024 | Stair railing construction. | ||

| HTMLPDF | 296-307-25027 | Requirements for railing dimensions. | ||

| HTMLPDF | 296-307-25030 | Requirements that apply to toeboards. | ||

| HTMLPDF | 296-307-25033 | Handrails and railings construction. | ||

| HTMLPDF | 296-307-25036 | Materials for floor opening covers. | ||

| HTMLPDF | 296-307-25039 | Constructing and mounting skylight screens. | ||

| HTMLPDF | 296-307-25042 | Protection the employer is required to provide for openings. | ||

| HTMLPDF | 296-307-260 | Fixed industrial stairs. | ||

| HTMLPDF | 296-307-26003 | Scope. | ||

| HTMLPDF | 296-307-26006 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-26009 | How to determine if fixed stairs are required. | ||

| HTMLPDF | 296-307-26012 | Spiral stairs. | ||

| HTMLPDF | 296-307-26015 | Strength requirements for fixed stairs. | ||

| HTMLPDF | 296-307-26018 | Width requirements for fixed stairs. | ||

| HTMLPDF | 296-307-26021 | Angle requirements for installing stairways. | ||

| HTMLPDF | 296-307-26024 | Requirements that apply to stair treads. | ||

| HTMLPDF | 296-307-26027 | Requirements that apply to the length of stairways. | ||

| HTMLPDF | 296-307-26030 | Requirements that apply to railings and handrails on fixed stairs. | ||

| HTMLPDF | 296-307-26033 | Requirements that apply to alternating tread-type stairs. | ||

| HTMLPDF | 296-307-26036 | Other requirements that apply to fixed stairs. | ||

| HTMLPDF | 296-307-270 | Aerial manlift equipment. | ||

| HTMLPDF | 296-307-27005 | Requirements that apply to aerial manlift equipment. | ||

| HTMLPDF | 296-307-27010 | Requirements that apply to using aerial manlift equipment. | ||

Part P Guarding Power Transmission Machinery | ||||

| HTMLPDF | 296-307-280 | Guarding power transmission machinery. | ||

| HTMLPDF | 296-307-28002 | Power transmission belts covered by this section. | ||

| HTMLPDF | 296-307-28004 | Definition of guarded by location. | ||

| HTMLPDF | 296-307-28006 | General requirements that apply to machine guarding. | ||

| HTMLPDF | 296-307-28014 | Requirements that apply to prime-mover guards. | ||

| HTMLPDF | 296-307-28016 | Guarding shafting. | ||

| HTMLPDF | 296-307-28018 | Guarding pulleys. | ||

| HTMLPDF | 296-307-28020 | Guarding horizontal belt, rope, and chain drives. | ||

| HTMLPDF | 296-307-28022 | Guarding overhead horizontal belt, rope, and chain drives. | ||

| HTMLPDF | 296-307-28024 | Guarding vertical and inclined belts. | ||

| HTMLPDF | 296-307-28026 | Guarding cone-pulley belts. | ||

| HTMLPDF | 296-307-28028 | Guarding belt tighteners. | ||

| HTMLPDF | 296-307-28030 | Guarding gears, sprockets, and chains. | ||

| HTMLPDF | 296-307-28032 | Guarding friction drives. | ||

| HTMLPDF | 296-307-28034 | Guarding keys, set screws, and other projections. | ||

| HTMLPDF | 296-307-28036 | Guarding collars and couplings. | ||

| HTMLPDF | 296-307-28038 | Self-lubricating bearings. | ||

| HTMLPDF | 296-307-28040 | Guarding clutches, cutoff couplings, and clutch pulleys. | ||

| HTMLPDF | 296-307-28042 | Guarding belt shifters, clutches, shippers, poles, perches, and fasteners. | ||

| HTMLPDF | 296-307-28044 | Materials required to use standard guards. | ||

| HTMLPDF | 296-307-28046 | Manufacturing standard guards. | ||

| HTMLPDF | 296-307-28048 | Disk, shield, and U-guards. | ||

| HTMLPDF | 296-307-28050 | Materials used for guards. | ||

| HTMLPDF | 296-307-28052 | Wood guards. | ||

| HTMLPDF | 296-307-28054 | Materials used for guarding horizontal overhead belts. | ||

| HTMLPDF | 296-307-28056 | Clearance maintained between guards and power transmission machinery. | ||

| HTMLPDF | 296-307-28058 | Construction of overhead rope and chain-drive guards. | ||

| HTMLPDF | 296-307-28060 | Materials used for guardrails and toeboards. | ||

| HTMLPDF | 296-307-28062 | Shafting maintenance. | ||

| HTMLPDF | 296-307-28064 | Pulley maintenance. | ||

| HTMLPDF | 296-307-28066 | Belt maintenance. | ||

| HTMLPDF | 296-307-28068 | Maintenance for other equipment. | ||

| HTMLPDF | 296-307-290 | Auger conveying equipment. | ||

| HTMLPDF | 296-307-29005 | Requirements that apply to auger conveying equipment. | ||

| HTMLPDF | 296-307-29010 | Other requirements that apply to auger conveying equipment manufactured after October 25, 1976. | ||

| HTMLPDF | 296-307-300 | Guarding farmstead equipment. | ||

| HTMLPDF | 296-307-30003 | Scope. | ||

| HTMLPDF | 296-307-30006 | Guarding power takeoff shafts of farmstead equipment. | ||

| HTMLPDF | 296-307-30009 | Guarding other power transmission components of farmstead equipment. | ||

| HTMLPDF | 296-307-30012 | Guarding functional components of farmstead equipment. | ||

| HTMLPDF | 296-307-30015 | Removing guards on farmstead equipment. | ||

| HTMLPDF | 296-307-30018 | Requirements that apply to electrical control used for maintaining and servicing farmstead equipment. | ||

| HTMLPDF | 296-307-30021 | Additional guarding requirements that apply to farmstead equipment. | ||

Part Q Control of Hazardous Energy (Lockout-tagout) | ||||

| HTMLPDF | 296-307-320 | Control of hazardous energy (lockout-tagout). | ||

| HTMLPDF | 296-307-32001 | Scope. | ||

| HTMLPDF | 296-307-32003 | Operations not in scope. | ||

| HTMLPDF | 296-307-32005 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-32007 | Required elements of an energy control program. | ||

| HTMLPDF | 296-307-32009 | Employer requirements for determining when to use lockout vs. tagout. | ||

| HTMLPDF | 296-307-32011 | Requirements that must be met to substitute tagout for lockout. | ||

| HTMLPDF | 296-307-32013 | Required elements for energy control procedures. | ||

| HTMLPDF | 296-307-32015 | Requirements that apply to lockout and tagout devices and materials. | ||

| HTMLPDF | 296-307-32017 | Inspecting the energy control procedure. | ||

| HTMLPDF | 296-307-32019 | General requirements that apply to energy control program training and communication. | ||

| HTMLPDF | 296-307-32021 | Additional requirements that apply to tagout training and communication. | ||

| HTMLPDF | 296-307-32023 | Employee retraining. | ||

| HTMLPDF | 296-307-32025 | Retention of training records. | ||

| HTMLPDF | 296-307-32027 | Qualifications to perform lockout or tagout. | ||

| HTMLPDF | 296-307-32029 | Notification of lockout and tagout. | ||

| HTMLPDF | 296-307-32031 | Order of events for lockout or tagout procedures. | ||

| HTMLPDF | 296-307-32033 | Order of events to be followed to remove lockout or tagout devices. | ||

| HTMLPDF | 296-307-32035 | Testing and positioning machines and equipment. | ||

| HTMLPDF | 296-307-32037 | Outside servicing contractors. | ||

| HTMLPDF | 296-307-32039 | Group lockout or tagout. | ||

| HTMLPDF | 296-307-32041 | Lockout/tagout during shift changes. | ||

Part R Safety Color Coding; Accident Prevention Signs and Tags | ||||

| HTMLPDF | 296-307-330 | Safety color coding; accident prevention signs and tags. | ||

| HTMLPDF | 296-307-33001 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-33003 | Use of red in safety color coding. | ||

| HTMLPDF | 296-307-33005 | Use of yellow in safety color coding. | ||

| HTMLPDF | 296-307-33007 | Use of "danger" versus "caution" on signs and tags. | ||

| HTMLPDF | 296-307-33009 | Design and color specifications for accident prevention signs. | ||

| HTMLPDF | 296-307-33011 | Proper uses of accident prevention tags. | ||

Part S Fire Protection and Ignition Sources; Exit Routes | ||||

| HTMLPDF | 296-307-340 | Portable fire extinguishers. | ||

| HTMLPDF | 296-307-34003 | Scope. | ||

| HTMLPDF | 296-307-34006 | Exemption from the requirements of this section. | ||

| HTMLPDF | 296-307-34009 | Portable fire extinguishers. | ||

| HTMLPDF | 296-307-34012 | Selection and distribution of portable fire extinguishers. | ||

| HTMLPDF | 296-307-34015 | Inspection, maintenance and testing of portable fire extinguishers. | ||

| HTMLPDF | 296-307-34018 | Hydrostatic testing. | ||

| HTMLPDF | 296-307-34021 | Training requirements for portable fire extinguishers. | ||

| HTMLPDF | 296-307-345 | Employee alarm systems. | ||

| HTMLPDF | 296-307-34503 | Scope. | ||

| HTMLPDF | 296-307-34506 | Employee alarm systems. | ||

| HTMLPDF | 296-307-34509 | Installation and restoration requirements for employee alarm systems. | ||

| HTMLPDF | 296-307-34512 | Employee alarm system maintenance and testing. | ||

| HTMLPDF | 296-307-34515 | Location(s) of manually operated devices. | ||

| HTMLPDF | 296-307-350 | Exit routes. | ||

| HTMLPDF | 296-307-35003 | Scope. | ||

| HTMLPDF | 296-307-35006 | Definitions apply to this section. | ||

| HTMLPDF | 296-307-35009 | Design requirements for exit routes. | ||

| HTMLPDF | 296-307-35012 | Operation and maintenance requirements for exit routes. | ||

| HTMLPDF | 296-307-35015 | Emergency action plan. | ||

| HTMLPDF | 296-307-35018 | Fire prevention plan. | ||

Part T Electrical | ||||

| HTMLPDF | 296-307-360 | Electrical. | ||

| HTMLPDF | 296-307-36005 | Scope. | ||

| HTMLPDF | 296-307-36010 | Definitions that apply to this part. | ||

| HTMLPDF | 296-307-362 | General electrical requirements. | ||

| HTMLPDF | 296-307-36203 | The following electrical equipment must be approved. | ||

| HTMLPDF | 296-307-36206 | Determining electrical equipment safety. | ||

| HTMLPDF | 296-307-36209 | Guarding live parts. | ||

| HTMLPDF | 296-307-36212 | Workspace that must be provided by the employer. | ||

| HTMLPDF | 296-307-36215 | Splices. | ||

| HTMLPDF | 296-307-36218 | Protection provided against combustible materials. | ||

| HTMLPDF | 296-307-36221 | Marking electrical equipment. | ||

| HTMLPDF | 296-307-36224 | Marking disconnecting means. | ||

| HTMLPDF | 296-307-36227 | Access and working space for electrical equipment of 600 volts, nominal, or less. | ||

| HTMLPDF | 296-307-36230 | Access and working space for electrical equipment over 600 volts, nominal. | ||

| HTMLPDF | 296-307-364 | Electrical installation and maintenance. | ||

| HTMLPDF | 296-307-36403 | Installation and maintenance of flexible cords and cables. | ||

| HTMLPDF | 296-307-36406 | Installation and maintenance of attachment plugs and receptacles. | ||

| HTMLPDF | 296-307-36409 | Safety measures employees must take when equipment causes electrical shock. | ||

| HTMLPDF | 296-307-36412 | Grounding and bonding requirements that apply to equipment installation and maintenance. | ||

| HTMLPDF | 296-307-36415 | Disconnecting means. | ||

| HTMLPDF | 296-307-36418 | Identification and load rating of electrical equipment. | ||

| HTMLPDF | 296-307-36421 | Installing equipment in wet locations. | ||

| HTMLPDF | 296-307-366 | Wiring design and protection. | ||

| HTMLPDF | 296-307-36603 | Use and identification of grounded and grounding conductors. | ||

| HTMLPDF | 296-307-36606 | Ampere rating for outlet devices. | ||

| HTMLPDF | 296-307-36609 | Conductors. | ||

| HTMLPDF | 296-307-36612 | Design and protection requirements that apply to service-entrances. | ||

| HTMLPDF | 296-307-36615 | Overcurrent protection. | ||

| HTMLPDF | 296-307-36618 | Grounding for premises wiring systems. | ||

| HTMLPDF | 296-307-36621 | Grounding the conductor in AC premises wiring. | ||

| HTMLPDF | 296-307-36624 | General requirements that apply to grounding conductors. | ||

| HTMLPDF | 296-307-36627 | Continuous path to ground. | ||

| HTMLPDF | 296-307-36630 | Grounding supports, enclosures, and equipment. | ||

| HTMLPDF | 296-307-36633 | Grounding fixed equipment. | ||

| HTMLPDF | 296-307-36636 | Grounding high voltage systems. | ||

| HTMLPDF | 296-307-368 | Wiring methods, components, and equipment for general use. | ||

| HTMLPDF | 296-307-36803 | Factory-assembled equipment. | ||

| HTMLPDF | 296-307-36806 | Temporary wiring. | ||

| HTMLPDF | 296-307-36809 | Cable trays. | ||

| HTMLPDF | 296-307-36812 | Open wiring on insulators. | ||

| HTMLPDF | 296-307-36815 | Wiring requirements that apply to cabinets, boxes, and fittings. | ||

| HTMLPDF | 296-307-36818 | Switches. | ||

| HTMLPDF | 296-307-36821 | Location of switchboards and panelboards. | ||

| HTMLPDF | 296-307-36824 | Insulating conductors. | ||

| HTMLPDF | 296-307-36827 | Use of flexible cords and cables. | ||

| HTMLPDF | 296-307-36830 | Identification, splicing and termination of flexible cords and cables. | ||

| HTMLPDF | 296-307-36833 | Multiconductor portable cable. | ||

| HTMLPDF | 296-307-36836 | Use of fixture wires. | ||

| HTMLPDF | 296-307-36839 | Wiring for lighting fixtures, lampholders, lamps, and receptacles. | ||

| HTMLPDF | 296-307-36842 | Wiring for receptacles, cord connectors, and attachment plugs (caps). | ||

| HTMLPDF | 296-307-36845 | Wiring for appliances. | ||

| HTMLPDF | 296-307-36848 | Wiring for motors, motor circuits, and controllers. | ||

| HTMLPDF | 296-307-36851 | Wiring for transformers. | ||

| HTMLPDF | 296-307-36854 | Wiring for capacitors. | ||

| HTMLPDF | 296-307-36857 | Ventilation for stored batteries. | ||

| HTMLPDF | 296-307-36860 | Miscellaneous requirements that apply to wiring methods. | ||

| HTMLPDF | 296-307-370 | Special purpose equipment and installations. | ||

| HTMLPDF | 296-307-37003 | Cranes, hoists, and runways. | ||

| HTMLPDF | 296-307-37006 | Elevators, dumbwaiters, escalators, and moving walks. | ||

| HTMLPDF | 296-307-37009 | Disconnecting means for electric welders. | ||

| HTMLPDF | 296-307-37012 | Electrically driven or controlled irrigation machines. | ||

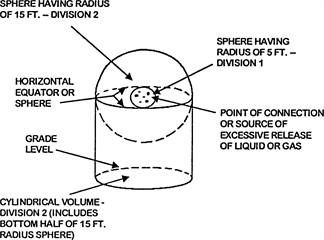

| HTMLPDF | 296-307-372 | Hazardous (classified) locations. | ||

| HTMLPDF | 296-307-37203 | Scope. | ||

| HTMLPDF | 296-307-37206 | Classifications that apply to this section. | ||

| HTMLPDF | 296-307-37209 | Equipment, wiring methods, and installations in hazardous locations. | ||

| HTMLPDF | 296-307-37212 | Installing conduit in hazardous locations. | ||

| HTMLPDF | 296-307-37215 | Equipment to be used in Division 1 and 2 locations. | ||

| HTMLPDF | 296-307-37218 | Motors and generators used in hazardous locations. | ||

| HTMLPDF | 296-307-374 | Special systems. | ||

| HTMLPDF | 296-307-37403 | Systems over 600 volts, nominal. | ||

| HTMLPDF | 296-307-37406 | Emergency power systems. | ||

| HTMLPDF | 296-307-37409 | Classification of Class 1, Class 2, and Class 3 remote control, signaling, and power-limited circuits. | ||

| HTMLPDF | 296-307-37412 | Fire protective signaling systems. | ||

| HTMLPDF | 296-307-376 | Working on or near exposed energized parts. | ||

| HTMLPDF | 296-307-37603 | Scope. | ||

| HTMLPDF | 296-307-37606 | Qualified person working on energized parts. | ||

| HTMLPDF | 296-307-37609 | Working near low voltage lines. | ||

| HTMLPDF | 296-307-37612 | Qualified persons working near overhead lines. | ||

| HTMLPDF | 296-307-37615 | Vehicles and mechanical equipment near overhead lines. | ||

| HTMLPDF | 296-307-37618 | Lighting for employees working near exposed energized parts. | ||

| HTMLPDF | 296-307-37621 | Working near exposed energized parts in confined spaces. | ||

| HTMLPDF | 296-307-37624 | Housekeeping requirements that apply to working near exposed energized parts. | ||

| HTMLPDF | 296-307-37627 | Qualified persons that may defeat an electrical safety interlock. | ||

| HTMLPDF | 296-307-378 | Safety-related work practices. | ||

| HTMLPDF | 296-307-37801 | Scope. | ||

| HTMLPDF | 296-307-37803 | Training employees on safety practices. | ||

| HTMLPDF | 296-307-37805 | Identification and use of safety-related work practices. | ||

| HTMLPDF | 296-307-37807 | Work on exposed deenergized parts. | ||

| HTMLPDF | 296-307-37809 | An employer must have a written copy of lockout-tagout procedures. | ||

| HTMLPDF | 296-307-37811 | Deenergizing equipment. | ||

| HTMLPDF | 296-307-37813 | Application of locks and tags. | ||

| HTMLPDF | 296-307-37815 | Verifying deenergization. | ||

| HTMLPDF | 296-307-37817 | Reenergizing equipment. | ||

| HTMLPDF | 296-307-37819 | Portable electric equipment. | ||

| HTMLPDF | 296-307-37821 | Electric power and lighting circuits. | ||

| HTMLPDF | 296-307-37823 | Test instruments and equipment. | ||

| HTMLPDF | 296-307-37825 | Flammable materials. | ||

| HTMLPDF | 296-307-380 | Electrical protective equipment. | ||

| HTMLPDF | 296-307-38003 | Use of protective equipment. | ||

| HTMLPDF | 296-307-38006 | General protective equipment and tools. | ||

| HTMLPDF | 296-307-38009 | Manufacturing and marking requirements that apply to electrical protective devices. | ||

| HTMLPDF | 296-307-38012 | Electrical requirements that apply to electrical protective devices. | ||

| HTMLPDF | 296-307-38015 | Workmanship and finish requirements that apply to electrical protective devices. | ||

| HTMLPDF | 296-307-38018 | Use and maintenance of electrical protective devices. | ||

SPECIALIZED OPERATIONS Part U-1 Hazardous Materials—Anhydrous Ammonia | ||||

| HTMLPDF | 296-307-400 | Anhydrous ammonia. | ||

| HTMLPDF | 296-307-40001 | Scope. | ||

| HTMLPDF | 296-307-40003 | Definitions that apply to this section. | ||

| HTMLPDF | 296-307-40005 | Storage and handling of anhydrous ammonia. | ||

| HTMLPDF | 296-307-40007 | Systems mounted on farm wagons (implements of husbandry) for the transportation of ammonia. | ||

| HTMLPDF | 296-307-40009 | Systems mounted on farm wagons (implements of husbandry) for the application of ammonia. | ||

| HTMLPDF | 296-307-40011 | Approved anhydrous ammonia equipment. | ||

| HTMLPDF | 296-307-40013 | Construction, original test, and requalification of nonrefrigerated containers. | ||

| HTMLPDF | 296-307-40015 | Marking nonrefrigerated containers and systems (other than DOT containers). | ||

| HTMLPDF | 296-307-40017 | Locations for anhydrous ammonia containers. | ||

| HTMLPDF | 296-307-40019 | Container accessories. | ||

| HTMLPDF | 296-307-40021 | Piping, tubing, and fittings. | ||

| HTMLPDF | 296-307-40023 | Specifications for hoses. | ||

| HTMLPDF | 296-307-40025 | Safety-relief devices. | ||

| HTMLPDF | 296-307-40027 | Emergency precautions when handling anhydrous ammonia. | ||

| HTMLPDF | 296-307-40029 | Filling densities. | ||

| HTMLPDF | 296-307-40031 | Transfer of liquids. | ||

| HTMLPDF | 296-307-40033 | Tank car unloading points and operations. | ||

| HTMLPDF | 296-307-40035 | Liquid-level gauging device. | ||

| HTMLPDF | 296-307-40037 | Maintenance of aboveground uninsulated containers. | ||

| HTMLPDF | 296-307-40039 | Electrical equipment and wiring. | ||

Part U-2 Hazardous Materials—Liquified Petroleum Gas | ||||

| HTMLPDF | 296-307-410 | Storage and handling of liquefied petroleum gases. | ||

| HTMLPDF | 296-307-41001 | Scope. | ||

| HTMLPDF | 296-307-41003 | LP-gas installations not covered by this part. | ||

| HTMLPDF | 296-307-41005 | Definitions that apply to this part. | ||

| HTMLPDF | 296-307-41007 | Odorizing LP-gas. | ||

| HTMLPDF | 296-307-41009 | Approval of LP-gas containers and equipment. | ||

| HTMLPDF | 296-307-41011 | Construction and test requirements for containers. | ||

| HTMLPDF | 296-307-41013 | Welding containers. | ||

| HTMLPDF | 296-307-41015 | Marking containers. | ||

| HTMLPDF | 296-307-41017 | Container locations. | ||

| HTMLPDF | 296-307-41019 | Valves and accessories. | ||

| HTMLPDF | 296-307-41021 | Piping, tubing, and fittings. | ||

| HTMLPDF | 296-307-41023 | Specifications for hoses. | ||

| HTMLPDF | 296-307-41025 | Safety devices. | ||

| HTMLPDF | 296-307-41027 | Construction and installation of indirect fired vaporizers. | ||

| HTMLPDF | 296-307-41029 | Construction and installation of atmospheric vaporizers. | ||

| HTMLPDF | 296-307-41031 | Construction and installation of direct gas-fired vaporizers. | ||

| HTMLPDF | 296-307-41033 | Construction and installation of direct gas-fired tank heaters. | ||

| HTMLPDF | 296-307-41035 | Construction and installation of dehydrators. | ||

| HTMLPDF | 296-307-41037 | Maximum filling densities. | ||

| HTMLPDF | 296-307-41039 | LP-gas in buildings. | ||

| HTMLPDF | 296-307-41041 | Transferring of liquids. | ||

| HTMLPDF | 296-307-41043 | Training for workers. | ||

| HTMLPDF | 296-307-41045 | Fire protection for LP-gas installations. | ||

| HTMLPDF | 296-307-41047 | Electrical requirements that apply to LP-gas installations. | ||

| HTMLPDF | 296-307-41049 | Liquid-level gauging devices. | ||

| HTMLPDF | 296-307-41051 | Requirements that apply to appliances. | ||

| HTMLPDF | 296-307-415 | Cylinder systems. | ||

| HTMLPDF | 296-307-41501 | Scope. | ||

| HTMLPDF | 296-307-41503 | Cylinder system. | ||

| HTMLPDF | 296-307-41505 | Marking containers used in cylinder systems. | ||

| HTMLPDF | 296-307-41507 | Additional requirements that apply to cylinder systems installed outdoors. | ||

| HTMLPDF | 296-307-41509 | Additional requirements that apply to cylinder system installed indoors. | ||

| HTMLPDF | 296-307-41511 | Valves and accessories. | ||

| HTMLPDF | 296-307-41513 | Safety devices for cylinder systems. | ||

| HTMLPDF | 296-307-41515 | Other requirements that apply to cylinder systems. | ||

| HTMLPDF | 296-307-420 | Systems using non-DOT containers. | ||

| HTMLPDF | 296-307-42001 | Scope. | ||

| HTMLPDF | 296-307-42003 | Design and classification of non-DOT containers. | ||

| HTMLPDF | 296-307-42005 | Valves and accessories, filler pipes, and discharge pipes for non-DOT containers. | ||

| HTMLPDF | 296-307-42007 | Additional requirements that apply to safety devices for non-DOT containers. | ||

| HTMLPDF | 296-307-42009 | Reinstallation of non-DOT containers. | ||

| HTMLPDF | 296-307-42011 | Maximum capacity for non-DOT containers. | ||

| HTMLPDF | 296-307-42013 | Installing non-DOT containers. | ||

| HTMLPDF | 296-307-42015 | Protecting non-DOT containers. | ||

| HTMLPDF | 296-307-42017 | Non-DOT containers in industrial plants. | ||

| HTMLPDF | 296-307-42019 | Container-charging plants. | ||

| HTMLPDF | 296-307-42021 | Fire protection for non-DOT containers. | ||

| HTMLPDF | 296-307-42023 | Other requirements that apply to non-DOT containers. | ||

| HTMLPDF | 296-307-425 | LP-gas as a motor fuel. | ||

| HTMLPDF | 296-307-42501 | Scope. | ||

| HTMLPDF | 296-307-42503 | Using LP-gas used as a motor fuel. | ||

| HTMLPDF | 296-307-42505 | Design and classification of fuel containers. | ||

| HTMLPDF | 296-307-42507 | Installing fuel containers. | ||

| HTMLPDF | 296-307-42509 | Valves and accessories. | ||

| HTMLPDF | 296-307-42511 | Piping, tubing, and fittings. | ||

| HTMLPDF | 296-307-42513 | Safety devices. | ||

| HTMLPDF | 296-307-42515 | Vaporizers. | ||

| HTMLPDF | 296-307-42517 | Gas regulating and mixing equipment. | ||

| HTMLPDF | 296-307-42519 | Maximum container capacity. | ||

| HTMLPDF | 296-307-42521 | Stationary engines used indoors. | ||

| HTMLPDF | 296-307-42523 | Portable engines used indoors. | ||

| HTMLPDF | 296-307-42525 | Industrial trucks used indoors. | ||

| HTMLPDF | 296-307-42527 | LP-gas-fueled vehicles to be garaged. | ||

| HTMLPDF | 296-307-430 | Storage of containers awaiting use or resale. | ||

| HTMLPDF | 296-307-43001 | Scope. | ||

| HTMLPDF | 296-307-43003 | Storage of containers. | ||

| HTMLPDF | 296-307-43005 | Containers stored within buildings frequented by the public. | ||

| HTMLPDF | 296-307-43007 | Containers stored in buildings not frequented by the public. | ||

| HTMLPDF | 296-307-43009 | Containers stored within special buildings or rooms. | ||

| HTMLPDF | 296-307-43011 | Containers stored outdoors. | ||

| HTMLPDF | 296-307-43013 | Fire protection provided for stored containers. | ||

| HTMLPDF | 296-307-435 | LP-gas system installations on commercial vehicles. | ||

| HTMLPDF | 296-307-43501 | Scope. | ||

| HTMLPDF | 296-307-43503 | Container construction. | ||

| HTMLPDF | 296-307-43505 | Maximum capacity allowed for LP-gas installations on commercial vehicles. | ||

| HTMLPDF | 296-307-43507 | Location of systems. | ||

| HTMLPDF | 296-307-43509 | Valves and accessories. | ||

| HTMLPDF | 296-307-43511 | Safety devices. | ||

| HTMLPDF | 296-307-43513 | Systems used on commercial vehicles. | ||

| HTMLPDF | 296-307-43515 | Enclosures and mounting. | ||

| HTMLPDF | 296-307-43517 | Piping, tubing, and fittings. | ||

| HTMLPDF | 296-307-43519 | Appliances. | ||

| HTMLPDF | 296-307-43521 | General precautions the employer must follow for LP-gas system installations on commercial vehicles. | ||

| HTMLPDF | 296-307-43523 | Containers to be charged. | ||

| HTMLPDF | 296-307-43525 | Fire protection for mobile cook units. | ||

| HTMLPDF | 296-307-440 | LP-gas service stations. | ||

| HTMLPDF | 296-307-44001 | Scope. | ||

| HTMLPDF | 296-307-44003 | Design and classification of storage containers. | ||

| HTMLPDF | 296-307-44005 | Valves and accessories. | ||

| HTMLPDF | 296-307-44007 | Safety devices. | ||

| HTMLPDF | 296-307-44009 | Maximum capacity allowed for containers. | ||

| HTMLPDF | 296-307-44011 | Installation of storage containers. | ||

| HTMLPDF | 296-307-44013 | Protecting equipment against tampering. | ||

| HTMLPDF | 296-307-44015 | Transport truck unloading point. | ||

| HTMLPDF | 296-307-44017 | Piping, valves, and fittings. | ||

| HTMLPDF | 296-307-44019 | Pumps and accessory equipment. | ||

| HTMLPDF | 296-307-44021 | LP-gas dispensing devices. | ||

| HTMLPDF | 296-307-44023 | Smoking is prohibited at LP-gas service stations. | ||

| HTMLPDF | 296-307-44025 | Fire protection at LP-gas service stations. | ||

Part U-3 Other Hazardous Materials Dipping and Coating Operations (Dip Tanks) | ||||

| HTMLPDF | 296-307-445 | Scope. | ||

| HTMLPDF | 296-307-450 | General requirements. | ||

Construction | ||||

| HTMLPDF | 296-307-45005 | Construct safe dip tanks. | ||

Ventilation | ||||

| HTMLPDF | 296-307-45010 | Provide proper ventilation for the vapor area. | ||

| HTMLPDF | 296-307-45015 | Additional precautions if recirculating ventilation system exhaust air into the workplace. | ||

| HTMLPDF | 296-307-45020 | Take additional precautions when using an exhaust hood. | ||

Inspection | ||||

| HTMLPDF | 296-307-45025 | Periodically inspect dip tanks and associated equipment and correct any deficiencies. | ||

First Aid | ||||

| HTMLPDF | 296-307-45030 | Make sure employees working near dip tanks know appropriate first-aid procedures. | ||

Cleaning | ||||

| HTMLPDF | 296-307-45035 | Prepare dip tanks before cleaning. | ||

Welding | ||||

| HTMLPDF | 296-307-45045 | Protect employees during welding, burning, or other work using open flames. | ||

Liquids Harmful to Skin | ||||

| HTMLPDF | 296-307-45050 | Protect employees that use liquids that may burn, irritate, or otherwise harm the skin. | ||

| HTMLPDF | 296-307-455 | Additional requirements for dip tanks using flammable or combustible liquids. | ||

Construction | ||||

| HTMLPDF | 296-307-45505 | Additional safeguards when constructing dip tanks. | ||

| HTMLPDF | 296-307-45510 | Provide overflow pipes. | ||

| HTMLPDF | 296-307-45515 | Provide bottom drains. | ||

Fire Protection | ||||

| HTMLPDF | 296-307-45520 | Fire protection in the vapor area. | ||

| HTMLPDF | 296-307-45525 | Additional fire protection for large dip tanks. | ||

Electrical Wiring and Equipment and Sources of Ignition | ||||

| HTMLPDF | 296-307-45535 | Prevention of static electricity sparks or arcs when adding liquids to a dip tank. | ||

| HTMLPDF | 296-307-45540 | Control ignition sources. | ||

| HTMLPDF | 296-307-45545 | Provide safe electrical wiring and equipment where the liquid can drip or splash. | ||

Housekeeping | ||||

| HTMLPDF | 296-307-45550 | Keep the area around dip tanks clear of combustible material and properly dispose of waste. | ||

Heating Liquid | ||||

| HTMLPDF | 296-307-45555 | Make sure heating the liquid in dip tanks does not cause a fire. | ||

Heat Drying | ||||

| HTMLPDF | 296-307-45560 | Make sure a heating system used for drying objects does not cause a fire. | ||

Conveyors | ||||

| HTMLPDF | 296-307-45565 | Make sure conveyor systems are safe. | ||

| HTMLPDF | 296-307-460 | Additional requirements for dip tanks used for specific processes. | ||

Hardening or Tempering | ||||

| HTMLPDF | 296-307-46005 | Meet specific requirements if using a hardening or tempering tank. | ||

Vapor Degreasing | ||||

| HTMLPDF | 296-307-46025 | Additional safeguards for vapor degreasing tanks. | ||

Spray Cleaning or Degreasing | ||||

| HTMLPDF | 296-307-46030 | Control liquid spray over an open surface cleaning or degreasing tank. | ||

| HTMLPDF | 296-307-465 | Definitions. | ||

Part V Welding | ||||

| HTMLPDF | 296-307-475 | Welding, cutting, and brazing. | ||

| HTMLPDF | 296-307-47501 | Definitions that apply to this part. | ||

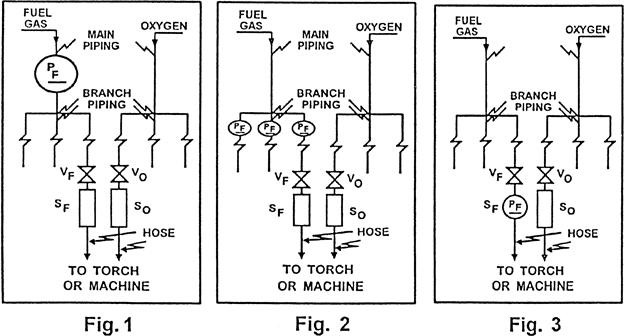

| HTMLPDF | 296-307-480 | Installation and operation of oxygen fuel gas systems for welding and cutting. | ||

| HTMLPDF | 296-307-48001 | Oxygen fuel gas systems. | ||

| HTMLPDF | 296-307-48003 | Portable cylinders. | ||

| HTMLPDF | 296-307-48005 | Storing compressed gas cylinders. | ||

| HTMLPDF | 296-307-48007 | Storing fuel-gas cylinders. | ||

| HTMLPDF | 296-307-48009 | Storing oxygen cylinders. | ||

| HTMLPDF | 296-307-48011 | Working with cylinders and containers. | ||

| HTMLPDF | 296-307-48013 | Safety devices on cylinders. | ||

| HTMLPDF | 296-307-48015 | Transporting cylinders. | ||

| HTMLPDF | 296-307-48017 | Handling cylinders. | ||

| HTMLPDF | 296-307-48019 | Cylinder valves. | ||

| HTMLPDF | 296-307-48021 | Cylinder regulators. | ||

| HTMLPDF | 296-307-48023 | Fuel-gas manifolds. | ||

| HTMLPDF | 296-307-48025 | High-pressure oxygen manifolds. | ||

| HTMLPDF | 296-307-48027 | Low-pressure oxygen manifolds. | ||

| HTMLPDF | 296-307-48029 | Manifolding portable outlet headers. | ||

| HTMLPDF | 296-307-48031 | Operating procedures for cylinder manifolds. | ||

| HTMLPDF | 296-307-48033 | Design of service piping systems. | ||

| HTMLPDF | 296-307-48035 | Piping joints. | ||

| HTMLPDF | 296-307-48037 | Installation of service piping systems. | ||

| HTMLPDF | 296-307-48039 | Painting and marking service piping systems. | ||

| HTMLPDF | 296-307-48041 | Testing service piping systems. | ||

| HTMLPDF | 296-307-48043 | Equipment installation. | ||

| HTMLPDF | 296-307-48045 | Protecting piping systems. | ||

| HTMLPDF | 296-307-48047 | Piping protective equipment. | ||

| HTMLPDF | 296-307-48049 | Station outlet protective equipment. | ||

| HTMLPDF | 296-307-48051 | Hose and hose connections. | ||

| HTMLPDF | 296-307-48053 | Pressure-reducing regulators. | ||

| HTMLPDF | 296-307-485 | Installation and operation of resistance welding equipment. | ||

| HTMLPDF | 296-307-48501 | Resistance welding equipment. | ||

| HTMLPDF | 296-307-48503 | Portable welding machines. | ||

| HTMLPDF | 296-307-48505 | Flash welding equipment. | ||

| HTMLPDF | 296-307-48507 | Job hazard analysis. | ||

| HTMLPDF | 296-307-48509 | Maintenance of resistance welding equipment. | ||

| HTMLPDF | 296-307-490 | Application, installation, and operation of arc welding and cutting equipment. | ||

| HTMLPDF | 296-307-49001 | Environmental conditions required to be taken into account when selecting arc welding equipment. | ||

| HTMLPDF | 296-307-49003 | Voltages when using arc welding equipment. | ||

| HTMLPDF | 296-307-49005 | Designing arc welding equipment. | ||

| HTMLPDF | 296-307-49007 | Installing arc welding equipment. | ||

| HTMLPDF | 296-307-49009 | Grounding arc welding equipment. | ||

| HTMLPDF | 296-307-49011 | Supply connections and conductors. | ||

| HTMLPDF | 296-307-49013 | Operating arc welding equipment. | ||

| HTMLPDF | 296-307-49015 | Maintaining arc welding equipment. | ||

| HTMLPDF | 296-307-495 | Fire prevention and protection. | ||

| HTMLPDF | 296-307-49501 | Basic fire prevention precautions. | ||

| HTMLPDF | 296-307-49503 | Special fire prevention precautions. | ||

| HTMLPDF | 296-307-49505 | Precautions to be taken when welding or cutting containers. | ||

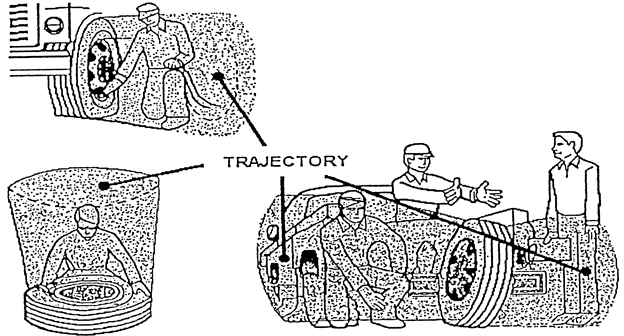

| HTMLPDF | 296-307-49507 | Precautions to be taken when welding in confined spaces. | ||

| HTMLPDF | 296-307-500 | Protection of employees. | ||

| HTMLPDF | 296-307-50001 | Eye protection. | ||

| HTMLPDF | 296-307-50003 | Specifications for eye protection. | ||

| HTMLPDF | 296-307-50005 | Protective clothing for welders. | ||

| HTMLPDF | 296-307-50007 | Other requirements that apply to employee protection. | ||

| HTMLPDF | 296-307-50009 | Employee protection for work in confined spaces. | ||

| HTMLPDF | 296-307-50011 | General requirements that apply to welding ventilation. | ||

| HTMLPDF | 296-307-50013 | Ventilation must be provided for general welding and cutting. | ||

| HTMLPDF | 296-307-50015 | Local exhaust hoods and booths. | ||

| HTMLPDF | 296-307-50017 | Ventilation must be provided in confined spaces. | ||

| HTMLPDF | 296-307-50019 | Welding fluorine compounds. | ||

| HTMLPDF | 296-307-50021 | Welding zinc. | ||

| HTMLPDF | 296-307-50023 | Welding lead. | ||

| HTMLPDF | 296-307-50025 | Welding beryllium. | ||

| HTMLPDF | 296-307-50027 | Welding cadmium. | ||

| HTMLPDF | 296-307-50029 | Welding mercury. | ||

Part W Powered Industrial Trucks (Forklifts) | ||||

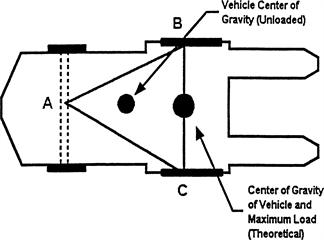

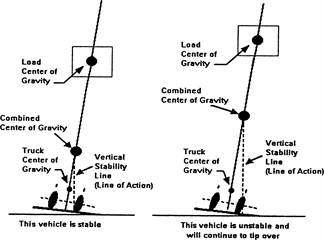

| HTMLPDF | 296-307-520 | Powered industrial trucks (forklifts). | ||

| HTMLPDF | 296-307-52001 | Scope. | ||

| HTMLPDF | 296-307-52003 | Powered industrial truck. | ||

| HTMLPDF | 296-307-52005 | Manufacturer's requirements that apply to powered industrial trucks. | ||

| HTMLPDF | 296-307-52007 | Classifications of powered industrial trucks. | ||

| HTMLPDF | 296-307-52009 | The employer must consider the following before choosing a powered industrial truck. | ||

| HTMLPDF | 296-307-52011 | Requirements for determining which trucks to use in specific hazardous environments. | ||

| HTMLPDF | 296-307-52013 | Using converted trucks. | ||

| HTMLPDF | 296-307-52015 | Overhead safety guards. | ||

| HTMLPDF | 296-307-52017 | Load backrests. | ||

| HTMLPDF | 296-307-52019 | Requirements that apply to fuel handling and storage. | ||

| HTMLPDF | 296-307-52021 | Lighting for operating areas. | ||

| HTMLPDF | 296-307-52023 | Carbon monoxide gas levels. | ||

| HTMLPDF | 296-307-52025 | Dockboards (bridge plates). | ||

| HTMLPDF | 296-307-52027 | Loading trucks, trailers, and railroad cars with powered industrial trucks. | ||

| HTMLPDF | 296-307-52029 | Operator training requirements for powered industrial trucks. | ||

| HTMLPDF | 296-307-52030 | Additional (nonmandatory) information that may assist with powered industrial truck operator training. | ||

| HTMLPDF | 296-307-52031 | Operating powered industrial trucks. | ||

| HTMLPDF | 296-307-52033 | Use of trucks to open or close freight car doors. | ||

| HTMLPDF | 296-307-52035 | Lifting employees on the forks of trucks. | ||

| HTMLPDF | 296-307-52037 | Using platforms for hoisting employees. | ||

| HTMLPDF | 296-307-52039 | Traveling in a powered industrial truck. | ||

| HTMLPDF | 296-307-52041 | Traveling speeds of powered industrial trucks. | ||

| HTMLPDF | 296-307-52043 | Loading powered industrial trucks. | ||

| HTMLPDF | 296-307-52045 | Servicing powered industrial trucks. | ||

| HTMLPDF | 296-307-52047 | Maintaining powered industrial trucks. | ||

Part X Rim Wheel Servicing | ||||

| HTMLPDF | 296-307-530 | Rim wheel servicing. | ||

| HTMLPDF | 296-307-53001 | Scope. | ||

| HTMLPDF | 296-307-53003 | Definitions that apply to rim wheel servicing. | ||

| HTMLPDF | 296-307-53005 | Employer provided training for employees who service rim wheels. | ||

| HTMLPDF | 296-307-53007 | Restraining devices. | ||

| HTMLPDF | 296-307-53009 | Equipment an employer must provide for rim wheel servicing. | ||

| HTMLPDF | 296-307-53011 | Wheel component assembly. | ||

| HTMLPDF | 296-307-53013 | Safe operating procedures for servicing multipiece rim wheels. | ||

| HTMLPDF | 296-307-53015 | Safe operating procedures for servicing single-piece rim wheels. | ||

| HTMLPDF | 296-307-53017 | Ordering the OSHA charts. | ||

Part Y Occupational Health Standards Part Y-1 Employer Chemical Hazard Communication

| ||||

Part Y-2 Material Safety Data Sheets and Label Preparation

| ||||

Part Y-3 Lighting | ||||

| HTMLPDF | 296-307-570 | Lighting rule. | ||

| HTMLPDF | 296-307-57005 | Provide and maintain adequate lighting. | ||

Part Y-4 Environmental Tobacco Smoke in the Office | ||||

| HTMLPDF | 296-307-590 | Environmental tobacco smoke in the office—Summary. | ||

| HTMLPDF | 296-307-59005 | Prohibit tobacco smoke in the office work environment. | ||

Part Y-5 Respirators | ||||

| HTMLPDF | 296-307-594 | Scope. | ||

| HTMLPDF | 296-307-596 | Respirator program administrator. | ||

| HTMLPDF | 296-307-59605 | Designate a program administrator. | ||

| HTMLPDF | 296-307-598 | Voluntary respirator use requirements. | ||

| HTMLPDF | 296-307-59805 | Make sure voluntary use of respirators is safe. | ||

| HTMLPDF | 296-307-59810 | Keep voluntary use program records. | ||

| HTMLPDF | 296-307-600 | Written respirator program and recordkeeping. | ||

| HTMLPDF | 296-307-60005 | Develop and maintain a written program. | ||

| HTMLPDF | 296-307-60010 | Keep respirator program records. | ||

| HTMLPDF | 296-307-602 | Respirator selection. | ||

| HTMLPDF | 296-307-60205 | Select and provide appropriate respirators. | ||

| HTMLPDF | 296-307-604 | Medical evaluations. | ||

| HTMLPDF | 296-307-60405 | Provide medical evaluations. | ||

| HTMLPDF | 296-307-606 | Fit testing. | ||

| HTMLPDF | 296-307-60605 | Conduct fit testing. | ||

| HTMLPDF | 296-307-608 | Training. | ||

| HTMLPDF | 296-307-60805 | Provide effective training. | ||

| HTMLPDF | 296-307-610 | Maintenance. | ||

| HTMLPDF | 296-307-61005 | Maintain respirators in a clean and reliable condition. | ||

| HTMLPDF | 296-307-61010 | Store respirators properly. | ||

| HTMLPDF | 296-307-61015 | Inspect and repair respirators. | ||

| HTMLPDF | 296-307-612 | Safe use and removal of respirators. | ||

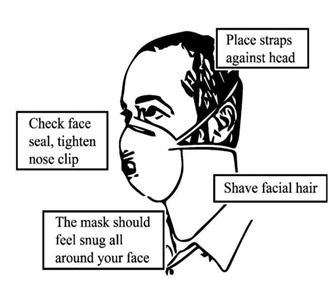

| HTMLPDF | 296-307-61205 | Prevent sealing problems with tight-fitting respirators. | ||

| HTMLPDF | 296-307-61210 | Make sure employees leave the use area before removing respirators. | ||

| HTMLPDF | 296-307-614 | Standby requirements for immediately dangerous to life or health (IDLH) conditions. | ||

| HTMLPDF | 296-307-61405 | Provide standby assistance in immediately dangerous to life or health (IDLH) conditions. | ||

| HTMLPDF | 296-307-616 | Air quality for self-contained breathing apparatus (SCBA) and air-line respirators. | ||

| HTMLPDF | 296-307-61605 | Make sure breathing air and oxygen meet established specifications. | ||

| HTMLPDF | 296-307-61610 | Prevent conditions that could create a hazardous breathing air supply. | ||

| HTMLPDF | 296-307-61615 | Make sure compressors do not create a hazardous breathing air supply. | ||

| HTMLPDF | 296-307-618 | Labeling of air-purifying respirator filters, cartridges, and canisters. | ||

| HTMLPDF | 296-307-61805 | Keep labels readable on respirator filters, cartridges, and canisters during use. | ||

| HTMLPDF | 296-307-620 | Required procedures for respiratory protection program. | ||

| HTMLPDF | 296-307-62005 | Use this medical questionnaire for medical evaluations. | ||

| HTMLPDF | 296-307-62010 | Follow these fit-testing procedures for tight-fitting respirators. | ||

| HTMLPDF | 296-307-62015 | Follow procedures established for cleaning and disinfecting respirators. | ||

| HTMLPDF | 296-307-62020 | Follow procedures established for seal checking respirators. | ||

| HTMLPDF | 296-307-622 | Definitions. | ||

Part Y-6 Respiratory Hazards | ||||

| HTMLPDF | 296-307-624 | Scope. | ||

| HTMLPDF | 296-307-626 | Evaluate and control employee exposures. | ||

| HTMLPDF | 296-307-62605 | Identify and evaluate respiratory hazards. | ||

| HTMLPDF | 296-307-62610 | Control employee exposures. | ||

| HTMLPDF | 296-307-62615 | Use respirators. | ||

| HTMLPDF | 296-307-62620 | Notify employees. | ||

| HTMLPDF | 296-307-62625 | Permissible exposure limits of air contaminants. | ||

| HTMLPDF | 296-307-628 | Definitions. | ||

Part Y-7 Hearing Loss Prevention (Noise) | ||||

| HTMLPDF | 296-307-630 | Scope. | ||

Hearing Loss Prevention Program | ||||

| HTMLPDF | 296-307-632 | Summary. | ||

| HTMLPDF | 296-307-63205 | Conduct employee noise exposure monitoring. | ||

| HTMLPDF | 296-307-63210 | Control employee noise exposures that equal or exceed 90 dBA TWA8. | ||

| HTMLPDF | 296-307-63215 | Make sure employees use hearing protection when their noise exposure equals or exceeds 85 dBA TWA8. | ||

| HTMLPDF | 296-307-63220 | Make sure exposed employees receive training about noise and hearing protection. | ||

| HTMLPDF | 296-307-63225 | Make sure warning signs are posted for areas where noise levels equal or exceed 115 dBA. | ||

| HTMLPDF | 296-307-63230 | Arrange for oversight of audiometric testing. | ||

| HTMLPDF | 296-307-63235 | Identification and correction of deficiencies in a hearing loss prevention program. | ||

| HTMLPDF | 296-307-63240 | Documenting hearing loss prevention activities. | ||

Noise Measurement and Computation | ||||

| HTMLPDF | 296-307-634 | Summary. | ||

| HTMLPDF | 296-307-63405 | Make sure that noise-measuring equipment meets recognized standards. | ||

| HTMLPDF | 296-307-63410 | Measure employee noise exposure. | ||

| HTMLPDF | 296-307-63415 | Use these equations when estimating full-day noise exposure from sound level measurements. | ||

Audiometric Testing | ||||

| HTMLPDF | 296-307-636 | Summary. | ||

| HTMLPDF | 296-307-63605 | Provide audiometric testing at no cost to employees. | ||

| HTMLPDF | 296-307-63610 | Establish a baseline audiogram for each exposed employee. | ||

| HTMLPDF | 296-307-63615 | Conduct annual audiograms. | ||

| HTMLPDF | 296-307-63620 | Review audiograms that indicate a standard threshold shift. | ||

| HTMLPDF | 296-307-63625 | Keep the baseline audiogram without revision, unless annual audiograms indicate a persistent threshold shift or a significant improvement in hearing. | ||

| HTMLPDF | 296-307-63630 | Make sure a record is kept of audiometric tests. | ||

| HTMLPDF | 296-307-63635 | Make sure audiometric testing equipment meets these requirements. | ||

Options to Audiometric Testing | ||||

| HTMLPDF | 296-307-638 | Summary. | ||

| HTMLPDF | 296-307-63805 | Conduct hearing protection audits at least quarterly. | ||

| HTMLPDF | 296-307-63810 | Make sure staff conducting audits are properly trained. | ||

| HTMLPDF | 296-307-63815 | Assess the hearing protection used by each employee during audits. | ||

| HTMLPDF | 296-307-63820 | Document hearing protection audits. | ||

Third-party Audiometric Tests | ||||

| HTMLPDF | 296-307-63825 | Make sure third-party hearing loss prevention programs meet the following requirements. | ||

| HTMLPDF | 296-307-640 | Noise definitions. | ||

Part Y-8 Confined Spaces | ||||

| HTMLPDF | 296-307-642 | Scope. | ||

| HTMLPDF | 296-307-644 | Summary. | ||

| HTMLPDF | 296-307-64402 | Identify permit-required confined spaces. | ||

| HTMLPDF | 296-307-64404 | Inform employees and control entry to permit-required confined spaces. | ||

| HTMLPDF | 296-307-64406 | The employer must follow these requirements when contracting with another employer to enter its confined space. | ||

Permit-required Confined Space Program | ||||

| HTMLPDF | 296-307-646 | Summary. | ||

| HTMLPDF | 296-307-64602 | Develop a written permit-required confined space program. | ||

| HTMLPDF | 296-307-64604 | Meet these additional requirements if employees enter another employer's confined space. | ||

Employee Training | ||||

| HTMLPDF | 296-307-648 | Summary. | ||

| HTMLPDF | 296-307-64802 | Provide employee training. | ||

| HTMLPDF | 296-307-64804 | Certify employee proficiency. | ||

Permit Entry Procedures | ||||

| HTMLPDF | 296-307-650 | Summary. | ||

| HTMLPDF | 296-307-65002 | Implement procedures for entry permits. | ||

| HTMLPDF | 296-307-65004 | Use an entry permit that contains all required information. | ||

| HTMLPDF | 296-307-65006 | Keep and review entry permits. | ||

| HTMLPDF | 296-307-65008 | Prevent unauthorized entry. | ||

| HTMLPDF | 296-307-65010 | Provide, maintain, and use proper equipment. | ||

| HTMLPDF | 296-307-65012 | Evaluate and control hazards for safe entry. | ||

| HTMLPDF | 296-307-65014 | Make sure adequate rescue and emergency services are available. | ||

| HTMLPDF | 296-307-65016 | Use nonentry rescue systems or methods whenever possible. | ||

| HTMLPDF | 296-307-65018 | Make sure entry supervisors perform their responsibilities and duties. | ||

| HTMLPDF | 296-307-65020 | Provide an attendant outside the permit-required confined space. | ||

| HTMLPDF | 296-307-65022 | Make sure entrants know the hazardous conditions and their duties. | ||

| HTMLPDF | 296-307-65024 | Implement procedures for ending entry. | ||

| HTMLPDF | 296-307-652 | Alternate entry procedures. | ||

| HTMLPDF | 296-307-65202 | Make sure the following conditions are met if using alternate entry procedures. | ||

| HTMLPDF | 296-307-65204 | Follow these alternate entry procedures for permit-required confined spaces. | ||

| HTMLPDF | 296-307-654 | Nonpermit confined spaces requirements. | ||

| HTMLPDF | 296-307-65402 | Follow these requirements when classifying a confined space as a nonpermit confined space. | ||

| HTMLPDF | 296-307-65404 | Reevaluate nonpermit confined spaces if hazards develop. | ||

| HTMLPDF | 296-307-656 | Definitions. | ||

Part Y-10 Emergency Response | ||||

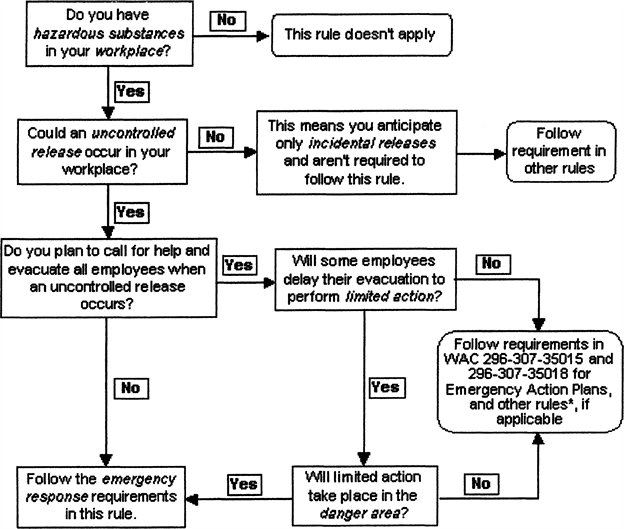

| HTMLPDF | 296-307-704 | Scope. | ||

| HTMLPDF | 296-307-70410 | Planning. | ||

| HTMLPDF | 296-307-70415 | Training. | ||

| HTMLPDF | 296-307-70420 | Medical surveillance. | ||

| HTMLPDF | 296-307-70425 | Keep records. | ||

| HTMLPDF | 296-307-70430 | Incident requirements. | ||

| HTMLPDF | 296-307-70435 | Implement and maintain an incident command system (ICS). | ||

| HTMLPDF | 296-307-70440 | Prepare skilled support personnel. | ||

| HTMLPDF | 296-307-70445 | Make sure the incident commander oversees activities during the response. | ||

| HTMLPDF | 296-307-70450 | Use the buddy system in danger areas. | ||

| HTMLPDF | 296-307-70455 | Provide rescue and medical assistance. | ||

| HTMLPDF | 296-307-70460 | Personal protective equipment. | ||

| HTMLPDF | 296-307-70465 | Control hazards created by personal protective equipment (PPE). | ||

| HTMLPDF | 296-307-70470 | Use personal protective equipment (PPE) properly. | ||

| HTMLPDF | 296-307-70475 | Postemergency response. | ||

| HTMLPDF | 296-307-70480 | Definitions. | ||

DISPOSITION OF SECTIONS FORMERLY CODIFIED IN THIS TITLE

| 296-307-015 | What must an employer do if a serious injury occurs? [Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-015, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-015, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-22-048, § 296-306A-015, filed 10/31/96, effective 12/1/96.] Repealed by WSR 15-11-066, filed 5/19/15, effective 7/1/15. Statutory Authority: RCW 49.17.010, 49.17.040, and 49.17.050. |

| 296-307-03910 | Make sure first-aid training contains required subjects. [Statutory Authority: RCW 49.17.010, [49.17].040, and [49.17].050. WSR 01-17-033, § 296-307-03910, filed 8/8/01, effective 9/1/01.] Repealed by WSR 04-07-160, filed 3/23/04, effective 5/1/04. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. |

| 296-307-03915 | Document your first-aid training. [Statutory Authority: RCW 49.17.010, [49.17].040, and [49.17].050. WSR 01-17-033, § 296-307-03915, filed 8/8/01, effective 9/1/01.] Repealed by WSR 04-07-160, filed 3/23/04, effective 5/1/04. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. |

| 296-307-03925 | Provide a first-aid station when required. [Statutory Authority: RCW 49.17.010, [49.17].040, and [49.17].050. WSR 01-17-033, § 296-307-03925, filed 8/8/01, effective 9/1/01.] Repealed by WSR 04-07-160, filed 3/23/04, effective 5/1/04. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. |

| 296-307-042 | Must an employer provide first-aid kits? [WSR 97-09-013, recodified as § 296-307-042, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-22-048, § 296-306A-042, filed 10/31/96, effective 12/1/96.] Repealed by WSR 01-17-033, filed 8/8/01, effective 9/1/01. Statutory Authority: RCW 49.17.010, [49.17].040, and [49.17].050. |

| 296-307-107 | Federal worker protection standards—Washington state department of agriculture. [Statutory Authority: RCW 49.17.050. WSR 09-17-119, § 296-307-107, filed 8/18/09, effective 10/1/09. Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-107, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-107, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-107, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-110 | Scope and purpose—Worker protection standards—40 C.F.R., § 170.1. [WSR 97-09-013, recodified as § 296-307-110, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-110, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-11005 | Definitions—Worker protection standards—40 C.F.R., § 170.3. [Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-11005, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-11005, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-11005, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-11010 | General duties and prohibited actions—Worker protection standards—40 C.F.R., § 170.7. [Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-11010, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-11010, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-11010, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-11015 | Violations of this part—Worker protection standards—40 C.F.R., § 170.9. [Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. WSR 09-07-098, § 296-307-11015, filed 3/18/09, effective 5/1/09; WSR 05-01-166, § 296-307-11015, filed 12/21/04, effective 4/2/05. WSR 97-09-013, recodified as § 296-307-11015, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-11015, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-120 | Applicability of this section—Standards for workers—40 C.F.R., § 170.102. [Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-120, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-120, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-120, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12005 | Exceptions—Standards for workers—40 C.F.R., § 170.103. [WSR 97-09-013, recodified as § 296-307-12005, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12005, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12010 | Exemptions—Standards for workers—40 C.F.R., § 170.104. [Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-12010, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-12010, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12010, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12015 | Restrictions associated with pesticide applications—Standards for workers—40 C.F.R., § 170.110. [Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-12015, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-12015, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12015, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12020 | Entry restrictions—Standards for workers—40 C.F.R., § 170.112. [Statutory Authority: RCW 49.17.050. WSR 09-17-119, § 296-307-12020, filed 8/18/09, effective 10/1/09. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. WSR 09-07-098, § 296-307-12020, filed 3/18/09, effective 5/1/09. Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-12020, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-12020, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12020, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12025 | Notice of applications—Standards for workers—40 C.F.R., § 170.120. [Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-12025, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-12025, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12025, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12030 | Providing specific information about applications—Standards for workers—40 C.F.R., § 170.122. [Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-12030, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-12030, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12030, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12035 | Notice of applications to handler employers—Standards for workers—40 C.F.R., § 170.124. [WSR 97-09-013, recodified as § 296-307-12035, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-08, § 296-306A-12035, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12040 | Pesticide safety training—Standards for workers—40 C.F.R., § 170.130. [Statutory Authority: RCW 49.17.010, [49.17].040, and [49.17].050. WSR 01-17-033, § 296-307-12040, filed 8/8/01, effective 9/1/01. Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-12040, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-12040, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12040, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12045 | Posted pesticide safety information—Standards for workers—40 C.F.R., § 170.135. [WSR 97-09-013, recodified as § 296-307-12045, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12045, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12050 | Decontamination—Standards for workers—40 C.F.R., § 170.150. [Statutory Authority: RCW 49.17.040. WSR 98-24-096, § 296-307-12050, filed 12/1/98, effective 3/1/99. WSR 97-09-013, recodified as § 296-307-12050, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12050, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |

| 296-307-12055 | Emergency assistance—Standards for workers—40 C.F.R., § 170.160. [WSR 97-09-013, recodified as § 296-307-12055, filed 4/7/97, effective 4/7/97. Statutory Authority: RCW 49.17.040, [49.17.]050 and [49.17.]060. WSR 96-20-082, § 296-306A-12055, filed 9/30/96, effective 11/1/96.] Repealed by WSR 19-21-169, filed 10/22/19, effective 2/3/20. Statutory Authority: RCW 49.17.040, 49.17.050, 49.17.280 and chapter 49.17 RCW. |