PDFWAC 296-155-33810

Metal mesh slings.

(1) Identification information on metal mesh slings. You must make sure all slings have legible identification information permanently attached to the sling which includes all of the following information:

(a) Name or trademark of the manufacturer;

(b) Rated loads for the types of hitches used, and the angle they're based on;

(c) Width and gauge;

(d) Number of legs, if more than one;

(e) Individual sling identification (e.g., serial numbers);

(f) Repairing agency, if the sling has ever been repaired.

(2) Inspection.

(a) A qualified person must inspect metal mesh slings before their initial use, according to Table 12, both:

(i) When the sling is new; and

(ii) Whenever a repair, alteration, or modification has been done.

(b) A qualified person must perform a visual inspection for damage, each day or shift the metal mesh sling is used. Immediately remove from service any sling damaged beyond the criteria in Table 12.

(c) A qualified person must perform periodic inspections on metal mesh slings according to Table 12.

(i) Inspect the entire length, including splices, end attachments, and fittings.

(ii) Remove slings from use if any of the conditions in Table 12 are found.

(iii) Keep a record of the most recent periodic inspection available, including the condition of the sling.

Note: | An external code mark on the sling is an acceptable means of recording the inspection as long as the code can be traced back to a record. |

Table 12

Metal Mesh Sling Inspection Table

Inspect metal mesh slings for conditions such as the following: | Perform inspections: | |||

• | Missing or illegible sling identification; | • | At least once a year for slings in normal service; | |

• | Broken welds along the sling edge; | • | At least once a quarter for slings in severe service; | |

• | Broken brazed joints along the sling edge; | • | As recommended by a qualified person for slings in special service. | |

• | Broken wire in any part of the mesh; | |||

• | Reduction in wire diameter of: | |||

– | 25% due to abrasion; | |||

– | 15% due to corrosion; | |||

• | Lack of flexibility due to the distortion of the mesh; | |||

• | Distortion of the choker fitting so the depth of the slot is increased by more than 10%; | |||

• | Distortion of either end fitting so the width of the eye opening is decreased by more than 10%; | |||

• | A 15% reduction of the original cross-sectional area of any point around the hook opening of the end fitting; | |||

• | Visible distortion of either end fitting out of its plane; | |||

• | Cracked end fitting; | |||

• | Slings in which the spirals are locked or without free articulation; | |||

• | Fittings that are pitted, corroded, cracked, bent, twisted, gouged, or broken; | |||

• | Other visible damage that raises doubt about the safety of the sling. | |||

(3) Repair, alteration, or modifications. You must repair metal mesh slings as follows:

(a) You must make sure slings are only repaired by the manufacturer or a qualified person;

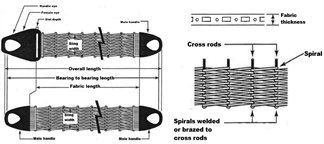

(b) Straightening of spiral or cross rods, or forcing a spiral into position is prohibited (see Figure 11);

(c) You must mark the sling to show the repairing agency;

(d) You must replace cracked, broken, bent or damaged metal mesh or components instead of repairing them;

(e) You must proof load test repaired slings according to subsection (4) of this section.

(4) Proof load testing.

(a) You must make sure the sling manufacturer or a qualified person proof load tests all new and repaired metal mesh slings before initial use;

(b) You must use a proof load test that is a minimum of two times the vertical hitch rated load.

(5) Rated load.

Note: | Rated loads are based on the following factors: |

• Strength of sling material; | |

• Design factor; | |

• Type of hitch; | |

• Angle of loading. |

(a) You must use metal mesh slings within the rated loads shown in Table 7 in ASME B30.9-2010. For angles that are not shown in these tables, use either the rated load for the next lower angle or one calculated by a qualified person.

(b) You must rate slings with the load capacity of the lowest rated component of the sling. For example, if fittings are rated lower than the sling material itself, identify the sling with the lower rated capacity.

(c) The use of horizontal sling angles less than 30 degrees is prohibited, unless recommended by the sling manufacturer or a qualified person.

(d) Rated loads for slings used in a choker hitch must conform to the values shown in the above referenced table, provided that the angle of choke is 120 degrees or greater.

(e) You must have the manufacturer or a qualified person determine the rated load if the angle of choke in a choker hitch is less than 120 degrees.

|

Figure 11 Metal Mesh Sling |

(6) Use of metal mesh slings.

(a) You must use metal mesh slings safely by doing all of the following:

(i) Shorten or adjust slings using only the methods approved by the manufacturer or a qualified person;

(ii) Sling legs must not be kinked;

(iii) Hitch slings in a way that provides control of the load.

(b) You must keep all parts of the human body from between the sling and the load, crane, or hoist hook.

(c) You must prohibit the following:

(i) The use of metal mesh slings as bridles on suspended personnel platforms;

(ii) Intentional shock loading;

(iii) Straightening a spiral or cross rod or forcing a spiral into position;

(iv) Avoid twisting and kinking.

Note: | Slings in contact with edges, corners, or protrusions should be protected with a material of sufficient strength, thickness, and construction to prevent damage. See Figure 3. |

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 16-09-085, § 296-155-33810, filed 4/19/16, effective 5/20/16. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW, and 29 C.F.R. 1926, Subpart CC. WSR 13-02-068, § 296-155-33810, filed 12/31/12, effective 2/1/13.]