Chapter 296-880 WAC

Last Update: 9/3/24UNIFIED SAFETY STANDARDS FOR FALL PROTECTION

WAC Sections

| HTMLPDF | 296-880-080 | Scope. |

| HTMLPDF | 296-880-090 | Quick reference guide. |

| HTMLPDF | 296-880-095 | Definitions. |

| HTMLPDF | 296-880-100 | Application. |

| HTMLPDF | 296-880-10005 | General requirements. |

| HTMLPDF | 296-880-10010 | Fall protection required regardless of height. |

| HTMLPDF | 296-880-10015 | Training. |

| HTMLPDF | 296-880-10020 | Fall protection work plan required at ten feet or more. |

| HTMLPDF | 296-880-200 | Fall protection required at four feet or more. |

| HTMLPDF | 296-880-20005 | Fall protection required at four feet or more. |

| HTMLPDF | 296-880-20010 | Exemption from fall protection requirements in this section. |

| HTMLPDF | 296-880-300 | Specific fall protection requirements. |

| HTMLPDF | 296-880-30005 | Construction work. |

| HTMLPDF | 296-880-30010 | Order pickers (PITS). |

| HTMLPDF | 296-880-30015 | Elevating work platforms. |

| HTMLPDF | 296-880-30020 | Powered platforms. |

| HTMLPDF | 296-880-30025 | Window cleaning. |

| HTMLPDF | 296-880-30030 | Scaffolds. |

| HTMLPDF | 296-880-30035 | Cranes. |

| HTMLPDF | 296-880-30040 | Telecommunication requirements that apply to wireless. |

| HTMLPDF | 296-880-30045 | Ship repairing, shipbuilding and shipbreaking. |

| HTMLPDF | 296-880-30050 | Longshore, stevedore, and waterfront related operations. |

| HTMLPDF | 296-880-30055 | Ski area facilities and operations. |

| HTMLPDF | 296-880-400 | Fall protection system specifications. |

| HTMLPDF | 296-880-40005 | Guardrail systems. |

| HTMLPDF | 296-880-40010 | Ramps, runways, and inclined walkway requirements. |

| HTMLPDF | 296-880-40015 | Cover requirements—Holes and openings. |

| HTMLPDF | 296-880-40020 | Personal fall arrest system requirements. |

| HTMLPDF | 296-880-40025 | Personal fall restraint system requirements. |

| HTMLPDF | 296-880-40030 | Positioning device system requirements. |

| HTMLPDF | 296-880-40035 | Self-rescue device requirements. |

| HTMLPDF | 296-880-40040 | Warning line system requirements. |

| HTMLPDF | 296-880-40045 | Safety monitor system requirements. |

| HTMLPDF | 296-880-40050 | Safety watch system requirements. |

| HTMLPDF | 296-880-40055 | Safety net system requirements. |

| HTMLPDF | 296-880-40060 | Catch platform requirements. |

| HTMLPDF | 296-880-40065 | Canopy requirements. |

| HTMLPDF | 296-880-40070 | Roof bracket requirements. |

| HTMLPDF | 296-880-40075 | Crawling board and chicken ladder requirements. |

| HTMLPDF | 296-880-40080 | Roof edge materials handling and material storage requirements. |

NONMANDATORY APPENDICES | ||

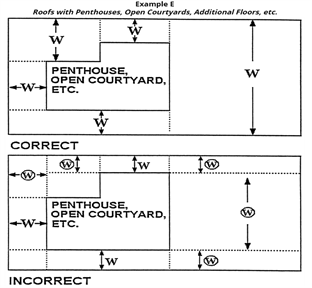

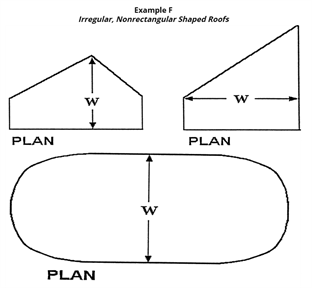

| HTMLPDF | 296-880-500 | Appendix A—Determining roof widths—Nonmandatory guidelines. |

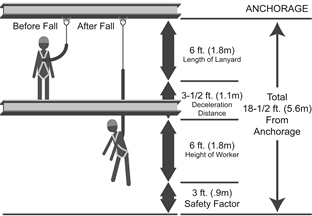

| HTMLPDF | 296-880-505 | Appendix B—Calculating fall clearance distance—Nonmandatory guidelines. |

| HTMLPDF | 296-880-510 | Appendix C—Test methods and additional guidelines for personal fall arrest systems—Nonmandatory guidelines. |

PDF296-880-080

Scope.

This chapter sets forth requirements for employers to provide and enforce the use of fall protection for employees performing activities covered under this chapter.

PDF296-880-090

Quick reference guide.

Unified Fall Protection Quick Reference Guide

General fall protection for all industries | Threshold height | WAC |

Above or adjacent to dangerous equipment | Regardless of height | |

Holes into which an employee can trip, step into, or step through | Regardless of height | |

Falling into or onto impalement hazards | Regardless of height | |

When on a walking/working surface | Four feet or more | |

Ramps, runways, and inclined walkways | Four feet or more | |

Holes where work is being performed | Four feet or more | |

Skylights | Four feet or more | 296-880-20005 (3)(b) |

Hatchway and chute holes | Four feet or more | 296-880-20005 (3)(c) |

Ladderways | Four feet or more | 296-880-20005 (3)(d) |

Pits and trap door holes | Four feet or more | 296-880-20005 (3)(e) |

Repair pits and service pits | Four feet or more | 296-880-20005 (3)(f) |

Manholes | Four feet or more | 296-880-20005 (3)(g) |

Openings | Four feet or more | |

Formwork and reinforcing work | Four feet or more | |

Steep pitch roof - Regardless of task | Four feet or more | |

Low pitch roof - Other than roofing work or constructing a leading edge | Four feet or more | |

Hazardous slopes | Four feet or more | |

Vehicles and rolling stock - If suitable anchorages cannot be provided or creates a greater hazard | Four feet or more | 296-880-20005(10) |

Specific requirements not addressed in WAC 296-880-200 (above) | ||

Construction work*See also chapter 296-155 WAC | ||

Roofing work on a low pitch roof | Six feet | |

Constructing a leading edge | Six feet | |

Engaged in the erection or placement of structural members | Ten feet | |

Engaged in excavation and trenching operations | Ten feet | |

Order pickers (PITS)*See also chapter 296-863 WAC | ||

Operators of order pickers | Regardless of height | 296-880-30010 (1) and (2) |

Elevating work platforms*See also chapter 296-869 WAC | ||

Vehicle mounted aerial devices | Regardless of height | |

Manually propelled and self-propelled elevating work platforms | Regardless of height if required by manufacturer | |

Boom supported elevating work platforms | Regardless of height | |

Powered platforms*See also chapter 296-870 WAC | ||

Working on a roof or other elevated working area | Four feet or more | |

Window cleaning*See also chapter 296-878 WAC | ||

Working on a roof or other elevated working area | Four feet or more | |

Scaffolds*See also chapter 296-874 WAC | ||

Working on a scaffold | Ten feet or more | |

Cranes - Under the scope of chapter 296-155 WAC, Part L | ||

For nonassembly/disassembly work | Six feet or more | |

For assembly/disassembly work | Ten feet or more | |

Towercranes - Work other than erecting, climbing, and dismantling | Six feet or more | 296-880-30035 (4)(a) |

Towercranes - Erecting, climbing, and dismantling work | Ten feet or more | 296-880-30035 (4)(b) |

Telecommunications work*See also chapter 296-32 WAC | Four feet or more | |

Qualified electrical workers*See also chapter 296-45 WAC | Four feet or more | |

Ship repairing, shipbuilding and shipbreaking*See also chapter 296-304 WAC | ||

Working aloft or elsewhere at elevation | Five feet or more | |

Longshore, stevedore and waterfront related operations*See also chapter 296-56 WAC | ||

Maintenance work on cranes, spouts, or similar types of equipment | Eight feet or more | |

Floor or wall openings or waterside edges, including bridges or gangway-like structures | Four feet or more | 296-880-30050 (2)(a) |

Ski area facilities and operations*See also chapter 296-59 WAC | ||

Working at unprotected elevated locations | Four feet or more | 296-880-30055 (1)(a) |

PDF296-880-095

Definitions.

For the purposes of this chapter the following definitions apply:

(1) Aerial device. A vehicle-mounted device, telescoping or articulating, or both, which is used to position personnel.

(2) Affected area. The distance away from the edge of an excavation equal to the depth of the excavation up to a maximum distance of 15 feet. For example, an excavation 10 feet deep has an affected area extending 10 feet from the edge of any side of the excavation.

(3) Anchorage. A secure point of attachment for lifelines, lanyards, or deceleration devices which is capable of withstanding the forces specified in this chapter.

(4) Boom-supported elevating work platform. A self-propelled, integral chassis, elevating work platform with a boom-supported platform that can be positioned completely beyond the base.

(5) Catch platform. A type of fall arrest system that consists of a platform installed within four vertical feet of the fall hazard, is at least 45 inches wide and is equipped with a standard guardrail system on all exposed sides.

(6) Catenary line. See "horizontal lifeline."

(7) Competent person. An individual knowledgeable of fall protection equipment, including the manufacturer's recommendations and instructions for the proper use, inspection, and maintenance; and who is capable of identifying existing and potential fall hazards; and who has the authority to take prompt corrective action to eliminate those hazards; and who is knowledgeable of the requirements contained in this chapter regarding the installation, use, inspection, and maintenance of fall protection equipment and systems.

(8) Connector. A device which is used to connect parts of the personal fall arrest system and positioning device systems together. It may be an independent component of the system, such as a carabiner, or it may be an integral component of part of the system (such as a buckle or D-ring sewn into a harness, or a snap hook spliced or sewn to a lanyard or self-retracting lanyard).

(9) Construction work. All or any part of excavation, construction, erection, alteration, repair, demolition, and dismantling of buildings and other structures and all operations in connection therewith; the excavation, construction, alteration and repair of sewers, trenches, caissons, conduits, pipe lines, roads and all operations pertaining thereto; the moving of buildings and other structures, and to the construction, alteration, repair, or removal of wharfs, docks, bridges, culverts, trestles, piers, abutments or any other construction, alteration, repair or removal work related thereto.

(10) Deceleration device. Any mechanism, such as a rope grab, ripstitch lanyard, specifically woven lanyard, tearing or deforming lanyards, automatic self-retracting lifelines/lanyards, etc., which serves to dissipate a substantial amount of energy during a fall arrest, or otherwise limit the energy imposed on an employee during fall arrest.

(11) Deceleration distance. The additional vertical distance a falling employee travels, excluding lifeline elongation and free fall distance, before stopping, from the point at which the deceleration device begins to operate. It is measured as the distance between the location of an employee's full body harness attachment point at the moment of activation (at the onset of fall arrest forces) of the deceleration device during a fall, and the location of that attachment point after the employee comes to a full stop.

(12) Dropline. A vertical lifeline secured to an upper anchorage for the purpose of attaching a lanyard or device.

(13) Elevating work platform. A device used to position personnel, along with their necessary tools and materials, at work locations. It includes a platform and an elevating assembly. It may be vehicle-mounted or have an integral chassis for mobility and as a means of support.

(14) Equivalent. Alternative designs, materials, or methods to protect against a hazard which the employer can demonstrate and will provide an equal or greater degree of safety for employees than the methods, materials, or designs specified in this standard.

(15) Fall arrest system. A fall protection system that will arrest a fall from elevation. Fall arrest systems include personal fall arrest systems that are worn by the user, catch platforms, and safety nets.

(16) Fall distance. The actual distance from the worker's support to the level where a fall would stop.

(17) Fall protection work plan. A written planning document in which the employer identifies all areas on the job site where a fall hazard of 10 feet or more exists. The plan describes the method or methods of fall protection to be used to protect employees, and includes the procedures governing the installation, use, inspection, and removal of the fall protection method or methods which are selected by the employer. See WAC 296-880-10020.

(18) Fall restraint system. A system in which all necessary components function together to restrain an employee from falling to a lower level. Types of fall restraint systems include standard guardrail systems or personal fall restraint systems.

(19) Feasible. It is possible to perform the work using a conventional fall protection system (i.e., guardrail system, safety net system, or personal fall arrest system) or that it is technologically possible to use any one of these systems to provide fall protection.

(20) Free fall. The act of falling before a personal fall arrest system begins to apply force to arrest the fall.

(21) Free fall distance. The vertical displacement of the fall arrest attachment point on the employee's full body harness between onset of the fall and just before the system begins to apply force to arrest the fall. This distance excludes deceleration distance, and lifeline/lanyard elongation, but includes any deceleration device slide distance or self-retracting lifeline/lanyard extension before they operate and fall arrest forces occur.

(22) Full body harness. A configuration of connected straps that meets the requirements specified in ANSI Z359.1, that may be adjustable to distribute a fall arresting force over at least the thighs, shoulders and pelvis, with provisions for attaching a lanyard, lifeline, or deceleration devices.

(23) Full body harness system. A full body harness and lanyard which is either attached to an anchorage meeting the requirements of this chapter; or it is attached to a horizontal or vertical lifeline which is properly secured to an anchorage(s) capable of withstanding the forces specified in this chapter.

(24) Handrail. A rail used to provide employees with a handhold for support.

(25) Hardware. Snap hooks, D-rings, bucklers, carabiners, adjusters, or O-rings, that are used to attach the components of a fall protection system together.

(26) Hazardous slope. A slope from which construction work is performed where normal footing cannot be maintained without the use of devices due to the pitch of the surface, weather conditions, or surface material.

(27) Hole. A gap or void two inches or more in its least dimension, in a floor, roof, or other surface.

(28) Horizontal lifeline. A rail, rope, wire, or synthetic cable that is installed in a horizontal plane between two anchorages and used for attachment of a worker's lanyard or lifeline device while moving horizontally; used to control dangerous pendulum like swing falls.

(29) Infrequent. The task or job is performed only on occasion, when needed (e.g., equipment breakdown), on an occasional basis, or at sporadic or irregular intervals.

(30) Lanyard. A flexible line of webbing, rope, or cable used to secure a positioning harness or full body harness to a lifeline or an anchorage point usually two, four, or six feet long.

(31) Leading edge. The advancing edge of a floor, roof, or formwork which changes location as additional floor, roof, or formwork sections are placed, formed, or constructed. A leading edge is considered to be an "unprotected side or edge" during periods when it is not actively and continuously under construction.

(32) Lifeline. A vertical line from a fixed anchorage or between two horizontal anchorages, independent of walking or working surfaces, to which a lanyard or device is secured. Lifeline as referred to in this text is one which is part of a fall protection system used as back-up safety for an elevated worker or as a restraint for workers on a flat or sloped surface.

(33) Locking snap hook. A connecting snap hook that requires two separate forces to open the gate; one to deactivate the gatekeeper and a second to depress and open the gate which automatically closes when released; used to minimize roll out or accidental disengagement.

(34) Low pitched roof. A roof having a slope equal to or less than four in 12.

(35) Maintenance. The work of keeping a building, machine, roadway, etc., in a state of good repair.

(36) Manually propelled elevating work platform. A manually propelled, integral chassis, elevating work platform with a platform that cannot be positioned completely beyond the base.

(37) Mechanical equipment. All motor or human propelled wheeled equipment except for wheelbarrows, mopcarts, robotic thermoplastic welders, and robotic crimpers.

(38) Opening. A gap or void 30 inches (76 cm) or more high and 18 inches (48 cm) or more wide, in a wall or partition, through which employees can fall to a lower level.

(39) Personal fall arrest system. A fall arrest system that is worn by the employee to arrest the employee in a fall from elevation. It consists of an anchor point, connectors, a full body harness, and may include a lanyard, deceleration device, lifeline, or suitable combinations of these.

(40) Personal fall restraint system. A fall restraint system that is worn by the employee to keep the employee from reaching a fall point, such as the edge of a roof or elevated work surface. It consists of an anchor point, hardware assemblies, a full body harness and may include a lanyard, restraint lines, or suitable combinations of these.

(41) Platform. A work surface elevated above the surrounding floor or ground.

(42) Positioning device system. A full body harness or positioning harness that is worn by an employee, and is rigged to allow an employee to be supported on an elevated vertical or inclined surface, such as a wall, pole or column and work with both hands free from the body support.

(43) Positioning harness. A body support that meets the requirements specified in ANSI Z359.1 that encircles and closes around the waist and legs with attachment elements appropriate for positioning work.

(44) Qualified person. One who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated his/her ability to solve or resolve problems related to the subject matter, the work, or the project.

(45) Repair. To restore a building, machine, roadway, etc., to an original state after damage or decay.

(46) Restraint line. A line from a fixed anchorage or between two anchorages to which an employee is secured in such a way as to prevent the worker from falling to a lower level.

(47) Roof. The exterior surface on the top of a building. This does not include floors or formwork which, because a building has not been completed, temporarily become the top surface of a building.

(48) Roofing work. The hoisting, storage, application, and removal of roofing materials and equipment, including related insulation, sheet metal, and vapor barrier work, but not including the construction of the roof deck.

(49) Rope grab. A fall arrester that is designed to move up or down a lifeline suspended from a fixed overhead or horizontal anchorage point, or lifeline, to which the full body harness is attached. In the event of a fall, the rope grab locks onto the lifeline rope through compression to arrest the fall. The use of a rope grab device is restricted for all restraint applications. See WAC 296-880-40025.

(50) Runway. A passageway for persons, elevated above the surrounding floor or ground level, such as a footwalk along shafting or a walkway between buildings.

(51) Safety line. See "lifeline."

(52) Safety monitoring system. A type of fall protection system allowed for use when roofing on a low pitched roof which consists of a warning line and a competent person whose only job responsibility is to recognize and warn employees of their proximity to fall hazards when working between the warning line and the unprotected sides and edges of a low pitch roof.

(53) Safety net system. A type of fall arrest system, as described in WAC 296-880-40055.

(54) Safety watch system. A type of fall protection system in which a competent person is responsible for recognizing and warning one employee of a fall hazard.

(55) Scaffold. A temporary elevated platform, including its supporting structure and anchorage points, used for supporting employees or materials.

(56) Self-propelled elevating work platform. A self-propelled, integral chassis, elevating work platform with a platform that cannot be positioned completely beyond the base.

(57) Self-rescue device. A piece of equipment designed to allow a person, who is suspended in a personal fall arrest system, to independently rescue themselves after the fall by moving the device up or down until they reach a surface and are no longer suspended.

(58) Self-retracting lifeline. A deceleration device which contains a wound line which may be slowly extracted from, or retracted onto, the device under slight tension during normal employee movement, and which after onset of a fall, automatically locks the drum and arrests the fall.

(59) Service. To repair or provide maintenance for.

(60) Shock absorbing lanyard. A flexible line of webbing, cable, or rope used to secure a full body harness to a lifeline or anchorage point that has an integral shock absorber.

(61) Snap hook. See "locking snap hook."

(62) Standard guardrail system. A type of fall restraint system that is a vertical barrier consisting of a top rail and midrail, and toeboard when used as falling object protection for persons who may work or pass below, that is erected along all open sides or edges of a walking/working surface, ramps, platforms, or runways.

(63) Standard strength and construction. Any construction of guardrails, handrails, covers, or other guards that meets the requirements of this chapter.

(64) Static line. See "horizontal lifeline."

(65) Steep pitched roof. A roof having a slope greater than four in 12.

(66) Structural member. A support that is a constituent part of any building or structure. Structural members include columns, girders, beams, trusses, joists, and similar supporting members of a building or structure.

(67) Suitable. That which fits, or has the qualities or qualifications to meet a given purpose, occasion, condition, function, or circumstance.

(68) Temporary. The duration of the task the worker performs is brief or short.

(69) Toeboard. A vertical barrier at floor level erected along all open sides or edges of a floor opening, platform, runway, ramp, or other walking/working surface to prevent materials, tools, or debris from falling onto persons passing through or working in the area below.

(70) Unprotected sides and edges. Any open side or edge of a floor, roof, balcony/deck, platform, ramp, runway, or walking/working surface where there is no standard guardrail system, or parapet wall of solid strength and construction that is at least 39 inches in vertical height.

(71) Walking/working surface. Any surface, whether horizontal or vertical on which an employee walks, works, or gains access to a work area or workplace location. Walking/working surfaces include, but are not limited to, floors, the ground, roofs, ramps, bridges, runways, stairs, dockboards, formwork, and reinforcing steel but not including ladders.

(72) Warning line system. A barrier erected on a walking and working surface or a low pitch roof (four in 12 or less), to warn employees that they are approaching an unprotected fall hazard(s).

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060, and chapter 19.17 [49.17] RCW. WSR 24-18-101, § 296-880-095, filed 9/3/24, effective 10/7/24. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. WSR 22-19-082, § 296-880-095, filed 9/20/22, effective 11/1/22. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060, and chapter 49.17 RCW. WSR 20-12-091, § 296-880-095, filed 6/2/20, effective 10/1/20.]

PDF296-880-100

Application.

Requirements that apply to all sections of this chapter.

PDF296-880-10005

General requirements.

(1) The employer must ensure that all surfaces on which employees will be working or walking on are structurally sound and will support them safely prior to allowing employees to work or walk on them.

(2) Inspection criteria.

(a) The employer must inspect all components (including hardware, lanyards, and positioning harnesses or full body harnesses depending on which system is used) of personal fall arrest systems, personal fall restraint systems, and positioning device systems prior to each use according to manufacturer's specifications for mildew, wear, damage, and other deterioration. The employer must remove defective components from service if their function or strength has been adversely affected.

(b) The employer must inspect safety nets at least once a week according to manufacturer's specifications for wear, damage, and other deterioration. The employer must also inspect safety nets after any occurrence which could affect the integrity of the safety net system. The employer must remove defective components from service. The employer must not use defective nets.

(3) The employer must only use personal fall arrest systems, personal fall restraint systems, positioning device systems, and their components for employee protection and not to hoist materials.

(4) The employer must plan for and provide prompt rescue of employees in the event of a fall or must assure the self-rescue capability of employees.

PDF296-880-10010

Fall protection required regardless of height.

(1) Regardless of height, the employer must guard open-sided floors, walkways, platforms, or runways above or adjacent to dangerous equipment, such as dip tanks and material handling equipment, and similar hazards with a standard guardrail system.

(2) The employer must guard holes into which an employee can trip, step into, or step through by a cover of standard strength and construction or a standard guardrail system.

Note: | Requirements for protecting employees from falling into or through holes where fall hazards of four feet or more are located in WAC 296-880-20005. |

(3) Regardless of height the employer must protect employees from falling into or onto impalement hazards, such as: Reinforcing steel (rebar), exposed steel, or wood.

PDF296-880-10015

Training.

(1) Provide fall protection training for employees exposed to fall hazards. The employer must provide training for each employee exposed to fall hazards. The training must enable each employee to recognize the hazards of falling and procedures to be followed in order to minimize those hazards.

(2) Each affected employee must be trained by a competent person to know at least the following:

(a) The nature of fall hazards in the work area;

(b) When fall protection is required;

(c) What fall protection is required;

(d) The correct procedures for erecting, maintaining, assembling, disassembling, and inspecting the fall protection systems to be used;

(e) The use and operation of fall protection systems used;

(f) Limitations of fall protection systems used;

(g) Proper care, maintenance, useful life, removal from service; and

(h) The requirements of this chapter.

(3) Make sure before an employee is allowed to perform work requiring the use of fall protection that the employee can:

(a) Demonstrate an understanding of the training specified above; and

(b) Demonstrate the ability to use fall protection properly.

(4) Retrain employees who use fall protection, if necessary. Retrain an employee when the employer has reason to believe the understanding, motivation, and skills required to use fall protection has not been retained. Circumstances where retraining is required include:

(a) Changes in the workplace that make previous training out of date;

(b) Changes in the types of fall protection to be used make previous training out of date; and

(c) Work habits or demonstrated knowledge indicate that the employee has not retained the necessary understanding, skill, or motivation to use fall protection.

(5) Document fall protection training. Document in writing that each employee has received and understood the required training. This documentation must include:

(a) Name of each employee;

(b) Date(s) of training;

(c) Subject(s) of the training; and

(d) Name or signature of the competent person who conducted the training, signature of the employer, or employers designee.

Note: | Documentation may be stored electronically as long as it is available to safety and health personnel from the department of labor and industries. |

PDF296-880-10020

Fall protection work plan required at ten feet or more.

(1) The employer must develop and implement a written fall protection work plan including each area of the work place where the employees are assigned and where fall hazards of ten feet or more exist.

(2) The fall protection work plan must:

(a) Identify all fall hazards in the work area;

(b) Describe the method of fall arrest or fall restraint to be provided;

(c) Describe the proper procedures for the assembly, maintenance, inspection, and disassembly of the fall protection system to be used;

(d) Describe the proper procedures for the handling, storage, and securing of tools and materials;

(e) Describe the method of providing overhead protection for workers who may be in, or pass through the area below the work area;

(f) Describe the method for prompt, safe removal of injured workers; and

(g) Be available on-site for inspection by the department.

(3) Prior to permitting employees into areas where fall hazards of ten feet or more exist the employer must ensure employees are trained and instructed in the items described in subsection (2)(a) through (f) of this section.

Note: | A fall protection work plan is not required where the use of a guardrail system eliminates the fall hazard. |

PDF296-880-200

Fall protection required at four feet or more.

This section sets forth requirements for the use of fall protection at four feet or more unless specifically addressed in WAC 296-880-300 of this chapter.

PDF296-880-20005

Fall protection required at four feet or more.

The employer must ensure that fall arrest systems, fall restraint systems, or positioning device systems are provided, installed, and implemented in accordance with WAC 296-880-400 Fall protection system specifications when employees are exposed to fall hazards of four feet or more to the ground or lower level.

(1) Walking/working surfaces with unprotected sides or edges. Except as required in subsections (2) through (10) of this section, the employer must ensure that each employee on a walking/working surface with an unprotected side or edge four feet or more above the ground or lower level is protected by one of the following fall protection systems:

(a) A standard guardrail system, or the equivalent, as specified in WAC 296-880-40005, on all open sides, except where there is entrance to a ramp, stairway, or ladder. The guardrail must be provided with a standard toeboard wherever: Beneath the open sides, persons can pass, there is moving machinery, or there is equipment with which falling materials could create a hazard.

(i) When employees are using stilts, the height of the top rail or equivalent member of the guardrail system must be increased (or additional rails may be added) an amount equal to the height of the stilts while maintaining the strength specifications of the guardrail system.

(ii) Where employees are working on or from platforms or ladders above the protection of the guardrail system, the employer must either increase the height of the guardrail system (or additional rails may be added) or select and implement another fall protection system as specified in (b), (c), (d), (e), or (f) of this subsection.

(iii) When guardrails must be temporarily removed to perform a specific task, the area must be constantly attended by an employee until the guardrail is replaced. The only duty the employee must perform is to warn persons entering the area of the fall hazard. The employee must be protected from the fall hazard by a personal fall arrest system or personal fall restraint system.

(b) A personal fall restraint system;

(c) A personal fall arrest system;

(d) A safety net system;

(e) A catch platform; or

(f) A warning line system.

(2) Guarding of ramps, runways, and inclined walkways.

(a) Ramps, runways, and inclined walkways that are four feet or more above the ground or lower level must be equipped with a standard guardrail system or the equivalent, as specified in WAC 296-880-40005, along each open side. Wherever tools, machine parts, or materials are likely to be used on the runway, a toeboard must also be installed on each open side to protect persons working or passing below.

(b) Runways used exclusively for special purposes may have the guardrail on one side omitted where operating conditions necessitate such omission, provided the falling hazard is minimized by using a runway not less than 18 inches wide.

Note: | See WAC 296-880-40010 for other specific criteria for ramps, runways, and inclined walkways. |

(3) Holes.

(a) The employer must protect employees from falling into or through holes four feet or more to the ground or lower level by one of the following fall protection systems:

(i) A standard guardrail system, or the equivalent, as specified in WAC 296-880-40005, on all open sides, except where there is entrance to a ramp, stairway, or ladder. The guardrail must be provided with a standard toeboard wherever, beneath the open sides, persons can pass, or there is moving machinery, or there is equipment with which falling materials could create a hazard;

(ii) A cover, as specified in WAC 296-880-40015;

(iii) A warning line system erected at least 15 feet from all unprotected sides or edges of the hole and meets the requirements of WAC 296-880-40040;

(iv) When the cover, guardrail system, or warning line system must be temporarily removed to perform a specific task, an employee must remain at the hole until the cover, guardrail system, or warning line system is replaced. The only duty the employee must perform is to warn persons entering the area of the fall hazard. The employee must be protected from the fall hazard by a personal fall arrest system or personal fall restraint system; or

(v) Personal fall arrest systems or personal fall restraint systems.

(b) The employer must guard skylight holes and skylights.

(i) Unprotected skylight holes must be guarded by covers of standard strength and construction, standard guardrail systems on all exposed sides, or employees must be protected by personal fall restraint systems, or personal fall arrest systems.

(ii) If the skylight has been installed and is not capable of supporting, without failure, at least twice the weight of employees, equipment, and materials that may be imposed on the skylight at any one time, the skylight must be guarded by a cover of standard strength and construction, a standard guardrail system on all sides, or employees must be protected by personal fall restraint systems, or personal fall arrest systems.

(c) The employer must guard hatchways and chute holes by one of the following:

(i) Hinged covers of standard strength and construction and a standard guardrail system with only one exposed side. When the hole is not in use, the cover must be closed or the exposed side must be guarded at both top and intermediate positions by removable standard guardrail systems; or

(ii) A removable standard guardrail system with toeboard on not more than two sides of the hole and fixed standard guardrail system with toeboards on all other exposed sides. The removable guardrail must be kept in a place when the hole is not in use and must be hinged or otherwise mounted so as to be conveniently replaceable.

(d) The employer must guard ladderways or platforms by a standard guardrail system with standard toeboards on all exposed sides, except at the entrance to a hole, with the passage through the guardrail either provided with a swinging gate or so offset that a person cannot walk directly into the hole.

(e) The employer must guard pits and trap door holes by covers of standard strength and construction. While the cover is not in place, the pit or trap door holes must be protected on all exposed sides by a standard guardrail system.

(f) The employer must guard repair pits, service pits, and assembly pits by a cover, a guardrail system, a fall restraint system or fall arrest system.

(g) The employer must guard manholes by standard covers which need not be hinged in place. While the cover is not in place, the hole must be constantly attended or must be protected by a removable standard guardrail system.

(4) Guarding of openings. The employer must ensure that each employee working on, at, above, or near openings (including those with chutes attached) where the outside bottom edge of the opening is four feet or more above a lower level and the inside bottom edge of the opening is less than 39 inches above the working surface, are protected from falling by the use of a guardrail system, a safety net system, a personal fall arrest system, or personal fall restraint system.

(5) Fall protection during form and reinforcing work. The employer must ensure that employees exposed to fall hazards of four feet or more while placing or tying reinforcing steel or working on the face of formwork or reinforcing steel are protected by personal fall arrest systems, positioning device systems, or safety net systems.

(6) Fall protection on steep pitched roofs. Regardless of the work activity, the employer must ensure that employees exposed to fall hazards of four feet or more while working on a roof with a pitch greater than four in 12 use one of the following:

(a) Fall restraint system. Safety monitor systems and warning line systems are prohibited on steep pitched roofs;

(b) A personal fall arrest system; or

(c) A positioning device system.

(7) Fall protection on low pitched roofs. The employer must ensure that employees exposed to fall hazards of four feet or more while engaged in work, other than roofing work or constructing a leading edge on low pitched roofs use one of the following:

(a) A personal fall restraint system;

(b) A personal fall arrest system;

(c) A positioning device system;

(d) A warning line system;

(e) A standard guardrail system;

(f) Safety watch system when work, other than construction work, is performed that is both infrequent and temporary, and not within six feet of the roof edge.

Exception: | When work, other than construction work, is performed 15 feet or more from the roof edge, the employer is not required to provide any fall protection, provided the work is both infrequent and temporary and the employer implements and enforces a work rule prohibiting employees from going within 15 feet of the roof edge without using fall protection in accordance with (a) through (f) of this subsection. |

(8) Hazardous slopes. Employees exposed to falls of four feet or more while performing construction work on a hazardous slope must use personal fall restraint systems or positioning device systems.

(9) Vehicles and rolling stock. The employer must ensure that employees exposed to fall hazards of four feet or more to the ground or lower level from vehicles or rolling stock on which employees must be located in order to perform their job duties are protected by fall arrest systems, fall restraint systems, or positioning device systems.

Exception: | Where suitable anchorages cannot be provided or when the use of fall protection creates a greater hazard, work may be performed on vehicles or rolling stock without a fall protection system. |

PDF296-880-20010

Exemption from fall protection requirements in this section.

Employees are exempt from WAC 296-880-20005 under the following conditions:

(1) During initial installation of the fall protection anchor prior to engaging in any work activity, or the disassembly of the fall protection anchor after all work activities have been completed.

(2) When employees are inspecting, investigating, or assessing roof level conditions or work to be performed only on low pitch roofs prior to the start of any work activity or after all work activities have been completed.

This exemption does not apply on steep pitch roofs, where construction work is underway, or when fall protection systems or equipment meeting the requirements of this chapter have been installed and are available for workers to use for pre-work and post-work inspections, investigations, or assessments.

Note: | Examples of activities the department recognizes as inspecting or estimating include: |

• Measuring a roof to determine the amount of materials needed for a project; | |

• Inspecting the roof for damage without removing equipment or components; and | |

• Assessing the roof to determine what method of fall protection will be provided to employees. |

Note: | Examples the department does not recognize as inspecting or estimating under this exemption include: |

• Delivering, staging or storing materials on a roof; and | |

• Persons estimating or inspecting on roofs that would be considered a "hazardous slope" by definition. |

PDF296-880-300

Specific fall protection requirements.

This section addresses specific fall protection requirements not already addressed in WAC 296-880-200 of this chapter.

PDF296-880-30005

Construction work.

This section applies to work activities under the scope of chapter 296-155 WAC, Safety standards for construction work, unless specifically addressed in WAC 296-880-200 of this chapter.

(1) The employer must ensure that a fall arrest system, fall restraint system, or positioning device system is provided, installed, and implemented in accordance with WAC 296-880-400 Fall protection system specifications when employees are exposed to fall hazards of six feet or more to the ground or lower level while:

(a) Engaged in roofing work on a low pitched roof;

(b) Constructing a leading edge.

Exceptions: | Employees not directly involved with constructing the leading edge, or are not performing roofing work must comply with WAC 296-880-200 Fall protection required at four feet or more. |

A safety monitoring system may be used when engaged in roofing work on a low pitched roof. |

(2) The employer must ensure that a fall arrest system, fall restraint system, or positioning device system is provided, installed, and implemented in accordance with WAC 296-880-400 Fall protection system specifications when employees are exposed to fall hazards of 10 feet or more to the ground or lower level while:

(a) Engaged in the erection or placement of structural members.

Exception: | When the erection or placement of structural members is performed on or from a floor, deck, roof, or similar surface you must comply with WAC 296-880-200 Fall protection required at four feet or more. |

(b) Engaged in excavation and trenching operations.

(i) Exceptions. Fall protection is not required at excavations when employees are:

(A) Directly involved with the excavation process and on the ground at the top edge of the excavation; or

(B) Working at an excavation site where appropriate sloping of side walls has been implemented as the excavation protective system.

(ii) Fall protection is required for employees standing in or working in the affected area of a trench or excavation exposed to a fall hazard of 10 feet or more; and:

(A) The employees are not directly involved with the excavation process; or

(B) The employees are on the protective system or any other structure in the excavation.

Note: | Persons considered directly involved in the excavation process include: |

1. Foreman of the crew. | |

2. Signal person. | |

3. Employee hooking on pipe or other materials. | |

4. Grade person. | |

5. State, county, or city inspectors inspecting the excavation or trench. | |

6. An engineer or other professional conducting a quality-assurance inspection. |

(3) Employees are exempt from WAC 296-880-30005 under the following conditions:

(a) During initial installation of the fall protection anchor prior to engaging in any work activity, or the disassembly of the fall protection anchor after all work activities have been completed;

(b) When employees are inspecting, investigating, or assessing roof level conditions or work to be performed only on low pitch roofs prior to the start of construction work or after all construction work has been completed;

This exemption does not apply on steep pitch roofs, where construction work is underway, or when fall protection systems or equipment meeting the requirements of this chapter have been installed and are available for workers to use for pre-work and post-work inspections, investigations, or assessments.

Note: | Examples of activities the department recognizes as inspecting or estimating include: |

• Measuring a roof to determine the amount of materials needed for a project; | |

• Inspecting the roof for damage without removing equipment or components; and | |

• Assessing the roof to determine what method of fall protection will be provided to employees. |

Note: | Examples the department does not recognize as inspecting or estimating under this exemption include: |

• Delivering, staging, or storing materials on a roof; and | |

• Persons estimating or inspecting on roofs that would be considered a "hazardous slope" by definition. |

(c) When employees must be located on vehicles, or rolling stock in order to perform their job duties.

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060, and chapter 19.17 [49.17] RCW. WSR 24-18-101, § 296-880-30005, filed 9/3/24, effective 10/7/24. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. WSR 22-19-082, § 296-880-30005, filed 9/20/22, effective 11/1/22. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060, and chapter 49.17 RCW. WSR 20-12-091, § 296-880-30005, filed 6/2/20, effective 10/1/20.]

PDF296-880-30010

Order pickers (PITS).

This section applies to powered industrial trucks under the scope of chapter 296-863 WAC, Forklifts and other powered industrial trucks.

(1) The employer must ensure all persons operating an order picker are protected by standard guardrails on all open sides; or

(2) A full body harness and lanyard that are connected to a tie-off point that has been approved by the PIT manufacturer.

Additional requirements for powered industrial trucks can be found in chapter 296-863 WAC, Forklifts and other powered industrial trucks.

PDF296-880-30015

Elevating work platforms.

(1) This section applies to the following types of elevating work platforms covered under the scope of chapter 296-869 WAC, Elevating work platforms:

(a) Aerial lifts;

(b) Manually propelled elevating work platforms that have a platform that cannot be positioned completely beyond the base;

(c) Self-propelled elevating work platforms that have a platform that cannot be positioned completely beyond the base;

(d) Boom-supported elevating work platforms that have a boom-supported platform that can be positioned completely beyond the base.

EXEMPTION: | This section does not apply to elevating work platforms used: |

1. By the fire services for fire combat that are covered by chapter 296-305 WAC, Safety standards for firefighters; or | |

2. For agriculture activities covered by chapter 296-307 WAC, Safety standards for agriculture. |

(2) This subsection applies to vehicle mounted aerial devices. Before elevating the platform, the employer must ensure all persons on the platform wear a full body harness with a lanyard attached to either:

(a) The manufacturer's recommended attachment point; or

(b) The boom or platform if the manufacturer does not specify an attachment point.

The employee must never attach a lanyard to an adjacent pole, structure, or equipment.

(3) This subsection applies to manually propelled and self-propelled elevating work platforms. Before elevating the platform, the employer must ensure all persons on the platform are wearing fall protection devices and other safety gear, if required by the manufacturer of the platform.

(4) This subsection applies to boom supported elevating work platforms. Before elevating the platform, the employer must ensure all persons on the platform of boom-supported elevating work platforms wear a full body harness and lanyard fixed to manufacturer provided and approved attachment points.

Additional requirements for elevating work platforms can be found in chapter 296-869 WAC, Elevating work platforms.

PDF296-880-30020

Powered platforms.

This section applies to permanent powered platform installations dedicated to interior or exterior building maintenance of a specific structure or group of structures under the scope of chapter 296-870 WAC, Powered platforms.

(1) Building owner certifications. The employer must obtain written certification from the building owner of any building with a powered platform installation that was completed or had major modification done after July 23, 1990, that the building and equipment meets the requirements of new installations-buildings in WAC 296-870-600 and new installations-equipment in WAC 296-870-700.

Note: | The building owner needs to base the certification on: |

1.The field test of the installation done before it is first placed into service or following any major modification to an existing installation; and | |

2. All other relevant available information including, but not limited to: | |

a. Test data; | |

b. Equipment specifications; | |

c. Verification by a registered professional engineer. |

(2) The employer must obtain written certification from the building owner that the installation:

(a) Has been inspected, tested, and maintained as required by inspection, testing, and maintenance in WAC 296-870-300; and

(b) All fall protection anchorages meet the requirements of WAC 296-880-40020.

(3) The employer must prohibit employees from using the installation until the building owner has provided the required written certifications.

(4) The employer must protect employees on working platforms with a personal fall arrest system that meets the requirements of WAC 296-880-40020.

(5) The employer must ensure employees working on a roof or other elevated working surface four feet or more above a lower level are protected in accordance with WAC 296-880-200.

Additional requirements for powered platforms can be found in chapter 296-870 WAC, Powered platforms.

PDF296-880-30025

Window cleaning.

This section applies to all window cleaning activities performed on the inside or outside of a building in which the window cleaner is working from a level that is located more than four feet above grade or lower level under the scope of chapter 296-878 WAC, Safety standards for window cleaning.

(1) The employer must ensure employees working on a roof or other elevated working surface four feet or more above a lower level are protected in accordance with WAC 296-880-200.

(2) The employer must ensure all workers suspended from a boatswain's chair or rope descent system use an independent fall arrest system where the fall arrest anchorage is separate from the suspension system anchorage.

(3) The employer must ensure workers assemble and wear their personal fall arrest equipment before they approach the point of suspension.

(4) The employer must ensure workers are connected at all times to the fall arrest system while they are suspended.

(5) The employer must prohibit use of the following equipment for window-cleaning operations:

(a) Portable sills;

(b) Window jacks;

(c) Capstan devices to suspend workers; and

(d) Suspension or fall-arrest ropes made entirely of polypropylene that do not have a minimum breaking strength of five thousand pounds (22.2 kN).

Additional requirements for window cleaning can be found in chapter 296-878 WAC, Safety standards for window cleaning.

PDF296-880-30030

Scaffolds.

This section applies to suspended and supported scaffolds under the scope of chapter 296-874 WAC, Scaffolds.

(1) The employer must protect each employee on a scaffold from falling ten feet or more to a lower level, by providing either:

(a) A personal fall arrest system; or

(b) Guardrails.

(2) The employer must ensure personal fall arrest systems are attached by a lanyard to one of the following:

(a) Vertical lifeline;

(b) Horizontal lifeline; or

(c) Appropriate structural member of the scaffold.

Note: | Specifications for these personal fall arrest systems can be found in WAC 296-880-40020. |

Note: | Specifications for guardrail systems used with scaffolds can be found in subsection (8) of this section. |

Note: | Specifications for vertical lifelines can be found in subsection (9) of this section. |

Note: | Specifications for horizontal lifelines can be found in subsection (10) of this section. |

(3) Provide fall protection for persons erecting or dismantling supported scaffolds.

(a) The employer must have a competent person determine the feasibility of providing fall protection for persons erecting or dismantling supported scaffolds.

(b) The employer must provide fall protection if the installation and use of fall protection is:

(i) Feasible; and

(ii) Does not create a greater hazard.

(4) The employer must ensure employees erecting the scaffold install the guardrail system, if required, before the scaffold is used by any other employees.

(5) Provide fall protection if a scaffold is too far from the work face. The employer must provide a guardrail system along the front edge of the platform, or have employees use a personal fall arrest system, if the distance from the front edge of the platform to the work face is greater than:

(a) Eighteen inches (46 cm) for scaffolds used for plastering and lathing operations;

(b) Fourteen inches (36 cm) for all other scaffolds.

(6) Provide specific types of fall protection for specific types of scaffolds.

(a) The employer must use a personal fall arrest system to protect employees on the following scaffolds:

(i) Boatswain's chair;

(ii) Catenary scaffold;

(iii) Float scaffold;

(iv) Ladder jack scaffold;

(v) Needle beam scaffold.

(b) The employer must use a personal fall arrest system and a guardrail system to protect employees on:

(i) Single-point adjustable suspension scaffolds; and

(ii) Two-point adjustable suspension scaffolds.

(7) The employer must protect employees working on a self-contained adjustable scaffold that has the platform:

(a) Supported by the frame structure, using a guardrail system with a minimum two-hundred pound top rail capacity;

(b) Suspended by ropes, using:

(i) A guardrail system with a minimum two-hundred pound top rail capacity; and

(ii) A personal fall arrest system.

(8) The employer must protect employees on walkways located within a scaffold by using a guardrail system that meets all of the following:

(a) Has a minimum two-hundred pound top rail capacity;

(b) Is installed within nine and one-half inches (24.1 cm) of the walkway; and

(c) Is installed along at least one side of the walkway.

(9) Ensure vertical lifelines used with personal fall arrest systems meet these requirements:

(a) The employer must make sure vertical lifelines are all of the following:

(i) Fastened to a fixed, safe point of anchorage;

(ii) Independent of the scaffold; and

(iii) Protected from sharp edges and abrasion.

Note: | Safe points of anchorage include structural members of buildings, but do not include: |

1. Standpipes, vents, or other piping systems; | |

2. Electrical conduit; | |

3. Outrigger beams; and | |

4. Counterweights. |

(b) The employer must ensure vertical lifelines, independent support lines, and suspension ropes are not attached to any of the following:

(i) Each other;

(ii) The same point of anchorage; or

(iii) The same point on the scaffold.

(c) The employer must ensure vertical lifelines, independent support lines, and suspension ropes do not use the same point of anchorage.

(d) The employer must ensure independent support lines and suspension ropes are not attached to a personal fall arrest system.

(e) The employer must ensure vertical lifelines are not used with single-point or two-point adjustable suspension scaffolds that have overhead components such as overhead protection or additional platform levels.

(10) Ensure horizontal lifelines used with personal fall arrest systems meet these requirements:

(a) The employer must equip single-point or two-point adjustable suspension scaffolds that use horizontal lifelines or structural members of the scaffold for fall protection with both of the following:

(i) Additional independent support lines that are equal in number and equivalent in strength to the suspension ropes; and

(ii) Automatic locking devices capable of stopping the scaffold from falling if one or both of the suspension ropes fail.

(b) The employer must make sure horizontal lifelines are secured to either:

(i) Two or more structural members of the scaffold; or

(ii) Looped around both the suspension ropes and independent support lines above the hoist and brake attached to the end of the scaffold.

(c) The employer must ensure independent support lines and suspension ropes are not:

(i) Attached to each other or the same point on the scaffold;

(ii) Attached to or use the same point of anchorage.

(d) The employer must ensure independent support lines and suspension ropes are not attached to either:

(i) A personal fall arrest system; or

(ii) The same point on the scaffold as a personal fall arrest system.

(e) The employer must ensure, if a horizontal lifeline is used where it may become a vertical lifeline, that the device used to connect a lanyard to the horizontal lifeline is capable of locking in both directions on the lifeline.

(11) The employer must ensure independent support lines and suspension ropes are not:

(a) Attached to each other or the same point on the scaffold;

(b) Attached to or use the same point of anchorage.

(12) The employer must ensure independent support lines and suspension ropes are not attached to either:

(a) A personal fall arrest system; or

(b) The same point on the scaffold as a personal fall arrest system.

(13) The employer must ensure, if a horizontal lifeline is used where it may become a vertical lifeline, that the device used to connect a lanyard to the horizontal lifeline is capable of locking in both directions on the lifeline.

(14) The employer must ensure guardrails, if required, are installed along all open sides and ends of platforms.

EXEMPTION: | For employees doing overhand bricklaying operations from a supported scaffold, a guardrail is not required on the side next to the wall. |

(15) The employer must ensure the height of the top rail, top edge, or the equivalent member, of supported scaffolds is:

(a) At least thirty-six inches (0.9 m) and not more than forty-five inches (1.2 m) above the platform surface for scaffolds manufactured or first placed in service before January 1, 2000;

(b) At least thirty-eight inches (0.97 m) and not more than forty-five inches (1.2 m) above the platform surface for scaffolds manufactured or first placed in service after January 1, 2000;

(c) The employer must ensure the height of the top rail, top edge, or the equivalent member, of suspended scaffolds that require guardrails and personal fall arrest systems, is at least thirty-six inches (0.9 m) and not more than forty-five inches (1.2 m) above the platform surface.

EXEMPTION: | When conditions warrant, the height of the top edge of the top rail may be greater than forty-five inches if the guardrail meets all other criteria of this section. |

(16) The employer must make sure the top edge of the top rail does not drop below the required height when the minimum load, shown in Table 2, Minimum Top Rail and Midrail Strength Requirements, is used.

(17) The employer must make sure each top rail and midrail, or equivalent member, of a guardrail system is able to withstand, without failure, the force shown in Table 1, Minimum Top Rail and Midrail Strength Requirements, when the force is applied as follows:

(a) To the top rail in a downward or horizontal direction at any point along its top edge;

(b) To the midrail in a downward or horizontal direction at any point.

Note: | Midrail includes screens, mesh, intermediate vertical members, solid panels, and equivalent structural members of the guardrail system. |

Table 1

Minimum Top Rail and Midrail Strength Requirements

Type of Scaffold | Top Rail Capacity | Midrail Capacity |

Single-point adjustable suspension scaffolds | 100 pounds (445 N) | 75 pounds (333 N) |

Two-point adjustable suspension scaffolds | ||

All other scaffolds | 200 pounds (890 N) | 150 pounds (666 N) |

Walkways within a scaffold |

(18) The employer must install midrails, screens, mesh, intermediate vertical members, solid panels, or equivalent structural members as follows:

(a) Midrails at a height approximately midway between the top edge of the guardrail system and the platform surface;

(b) Screens and mesh:

(i) From the top edge of the guardrail system to the scaffold platform; and

(ii) Along the entire opening between the supports.

(c) Intermediate members, such as balusters or additional rails, not more than nineteen inches (48 cm) apart.

(19) The employer must make sure steel or plastic banding is not used as a top rail or midrail.

(20) The employer must have a competent person inspect manila rope and plastic or other synthetic rope that is used as a top rail or midrail as frequently as necessary to make sure it continues to meet the strength requirements for a top rail or midrail.

Note: | Crossbraces may be used as a top rail or midrail in a guardrail system if they meet the following requirements: |

1. The crossing point of the two braces is between: | |

a. 20" and 30" above the work platform when used as a midrail. | |

b. 38" and 48" above the work platform when used as a top rail. | |

2. The end points at each upright are not more than 48" apart. |

Additional requirements for scaffolds can be found in chapter 296-874 WAC, Scaffolds.

PDF296-880-30035

Cranes.

This section applies to all cranes covered under the scope of chapter 296-155 WAC, Part L, Cranes, rigging, and personnel lifting.

(1) Fall protection systems:

(a) Personal fall arrest systems must conform to the criteria in WAC 296-880-40020.

(b) Personal fall restraint systems must conform to the criteria in WAC 296-880-40025.

(c) Positioning device systems must conform to the criteria in WAC 296-880-40030.

(2) For nonassembly/disassembly work on cranes/derricks except tower cranes, the employer must provide and ensure the use of fall protection equipment for employees six feet or more above a lower level as follows:

(a) When moving point-to-point:

(i) On nonlattice booms (whether horizontal or not horizontal);

(ii) On lattice booms that are not horizontal;

(iii) On horizontal lattice booms where the fall distance is ten feet or more above a lower level.

(b) While at a work station on any part of the crane (including the boom, of any type).

Note: | If the equipment is running and the employee is at or near the draw-works, precautions should be taken to ensure the fall protection gear will not become entangled. |

(3) For assembly/disassembly work on cranes/derricks except tower cranes, the employer must provide and ensure the use of fall protection equipment for employees ten feet or more above a lower level.

Note: | If the equipment is running and the employee is at or near the draw-works, precautions should be taken to ensure the fall protection gear will not become entangled. |

(4) Tower cranes.

(a) For work other than erecting, climbing, and dismantling, the employer must provide and ensure the use of fall protection equipment for employees six feet or more above a lower level.

Note: | If the equipment is running and the employee is at or near the draw-works, precautions should be taken to ensure the fall protection gear will not become entangled. |

(b) For erecting, climbing, and dismantling work, the employer must provide and ensure the use of fall protection equipment for employees ten feet or more above a lower level.

(5) Anchorage criteria applicable to all cranes.

(a) Anchorages used for attachment of personal fall arrest equipment must be independent of any anchorage being used to support or suspend platforms and capable of supporting at least five thousand pounds (22.2 kN) per employee attached, or must be designed, installed, and used as follows:

(i) As part of a complete personal fall arrest system which maintains a safety factor of at least two; and

(ii) Under the supervision of a qualified person.

(b) Positioning devices must be secured to an anchorage capable of supporting at least twice the potential impact load of an employee's fall or three thousand pounds (13.3 kN), whichever is greater.

(c) Anchorages for personal fall arrest and positioning device systems.

(i) Personal fall arrest systems may be anchored to any apparently substantial part of the equipment unless a competent person, from a visual inspection, without an engineering analysis, would conclude that the criteria in (a) of this subsection would not be met.

(ii) Positioning device systems may be anchored to any apparently substantial part of the crane unless a competent person, from a visual inspection, without an engineering analysis, would conclude that the criteria in (b) of this subsection would not be met.

(iii) Attachable anchor devices (portable anchor devices that are attached to the crane) must meet the anchorage criteria in (a) of this subsection for personal fall arrest systems and (b) of this subsection for positioning device systems.

(d) Anchorages for fall restraint systems. Fall restraint systems may be anchored to any part of the crane that is capable of withstanding twice the maximum load that an employee may impose on it during reasonably anticipated conditions of use.

(e) Anchoring to the load line. A personal fall arrest system is permitted to be anchored to the crane/derrick's hook (or other part of the load line) where all of the following requirements are met:

(i) A qualified person has determined that the set-up and rated capacity of the crane/derrick (including the hook, load line, and rigging) meets or exceeds the requirements in (a) of this subsection;

(ii) The crane operator must be at the worksite and informed that the crane is being used for this purpose; and

(iii) No load is suspended from the load line when the personal fall arrest system is anchored to the crane/derrick's hook (or other part of the load line).

(6) Training. The employer must train each employee who may be exposed to fall hazards while on, or hoisted by, cranes/derricks covered by this section in accordance with WAC 296-880-10015.

Additional requirements for cranes can be found in chapter 296-155 WAC, Part L, Cranes, rigging and personnel lifting.

PDF296-880-30040

Telecommunication requirements that apply to wireless.

Requirements for telecommunications can be found in chapter 296-32 WAC, Safety standards for telecommunications.

PDF296-880-30045

Ship repairing, shipbuilding and shipbreaking.

This section applies to all ship repairing, shipbuilding and shipbreaking industries and operations under the scope of chapter 296-304 WAC, Safety standards for ship repairing, shipbuilding and shipbreaking.

(1) The employer must provide and ensure the use of fall protection when employees work aloft or elsewhere at elevations more than five feet above a solid surface.

(2) Guarding of deck openings and edges.

(a) When employees are working in the vicinity of flush manholes and other small openings of comparable size in the deck and other working surfaces, such openings must be suitably covered or guarded to a height of not less than thirty inches, except where the use of such guards is made impracticable by the work actually in progress.

(b) When employees are working around open hatches not protected by coamings to a height of twenty-four inches or around other large openings, the edge of the opening must be guarded in the working area to a height of thirty-six to forty-two inches, except where the use of such guards is made impracticable by the work actually in progress.

(c) When employees are exposed to unguarded edges of decks, platforms, flats, and similar flat surfaces, more than five feet above a solid surface, the edges must be guarded by adequate guardrails meeting the requirements of WAC 296-304-05001 (9)(a) and (b), unless the nature of the work in progress or the physical conditions prohibit the use or installation of such guardrails.

(d) When employees are working near the unguarded edges of decks of vessels afloat, they must be protected by buoyant personal flotation devices, meeting the requirements of WAC 296-304-09017(1).

(e) Sections of bilges from which floor plates or gratings have been removed must be guarded by guardrails except where they would interfere with work in progress. If these open sections are in a walkway at least two ten-inch planks placed side by side, or equivalent, must be laid across the opening to provide a safe walking surface.

(f) Gratings, walkways, and catwalks, from which sections or ladders have been removed, must be barricaded with adequate guardrails.

Additional requirements for ship repairing, shipbuilding and shipbreaking can be found in chapter 296-304 WAC, Safety standards for ship repairing, shipbuilding and shipbreaking.

PDF296-880-30050

Longshore, stevedore, and waterfront related operations.

This section applies to any and all waterfront operations under the scope of chapter 296-56 WAC, Safety standards—Longshore, stevedore, and waterfront related operations.

(1) The employer must ensure employees doing maintenance work on cranes, spouts or similar types of equipment, eight feet or more above the ground or surface and not in an area that is protected by any standard safeguards such as walkways with standard railings, or ladders with protective cages, wear a full body harness and lanyard which can be attached to the structure.

(2) Guarding of edges. The employer must meet the following requirements for employee protection:

(a) Guardrails must be provided at locations where employees are exposed to falls of more than four feet from floor or wall openings or waterside edges, including bridges or gangway-like structures leading to pilings, vessel mooring or berthing installations.

(b) Guardrails are not required:

(i) At loading platforms and docks;

(ii) At waterside edges used for cargo or mooring line handling;

(iii) On the working sides of work platforms, skids, or similar workplaces which abut the work area; or

(iv) On railroad rolling stock, highway vehicles, intermodal containers, or similar equipment.

(c) Where guardrails are impractical due to machinery requirements or work processes, an alternate means of fall protection, such as nets, must be used.

(3) The employer must ensure guardrails meet the following criteria:

(a) Guardrails must be capable of withstanding a force of at least two hundred pounds (890 N) applied in any direction at mid-span of the top rail (when used), or at the uppermost point if there is no guardrail.

(b) If not of solid baluster, grillwork, slatted, or similar construction, guardrails must consist of top rails and midrails. Midrails, when used, must be positioned at approximately half the height of the top rail.

(c) The top surface of guardrails installed before October 3, 1983, must be at least thirty-six inches (.091 m) high. Those installed after October 3, 1983, must be forty-two inches (1.07 m) high, plus or minus two inches (5.1 cm), high.

(d) Any nonrigid railing such as chain or wire rope must have a maximum sag, at the mid-point between posts, of not more than six inches (15.24 cm).

(e) Top rails must be free of sharp edges and maintained in good repair.

(f) Rail ends must not overhang. This does not prohibit scrollwork, boxed ends or similar nonhazardous projections.

(4) The employer must provide toeboards when employees below could be exposed to falling objects such as tools. Toeboards must be at least three and one-half inches (8.9 cm) in height from top edge to floor level, and be capable of withstanding a force of fifty pounds (222 N) applied in any direction. Drainage clearance not in excess of one-eighth inch under toeboards is permitted.

(5) Stair railings must be capable of withstanding a force of at least two hundred pounds (890 N) applied in any direction, and must not be more than thirty-six inches (0.91 m) nor less than thirty-two inches (0.81 m) in height from the upper top rail surface to the tread surface in line with the leading edge of the tread. Railings and midrails must be provided at any stairway having four or more risers, as follows:

(a) For stairways less than forty-four inches (1.12 m) wide, at least one railing; and

(b) For stairways more than forty-four inches (1.12 m) but less than eighty-eight inches (2.24 m) wide, a stair rail or handrail on each side, and if eighty-eight or more inches wide, an additional intermediate handrail.

(6) The employer must maintain railings in good repair and free of sharp edges.

Additional requirements for longshore, stevedore and waterfront related operations can be found in chapter 296-56 WAC, Safety standards for longshore, stevedore and waterfront related operations.

PDF296-880-30055

Ski area facilities and operations.

This section applies to all persons, firms, corporations, or others engaged in the operation of organized ski areas and facilities under the scope of chapter 296-59 WAC, Safety standards for ski area facilities and operations.

(1) Personal protective equipment, general requirements.

(a) Personal fall arrest systems or personal fall restraint systems must be provided and used whenever employees are working in locations which expose them to a fall hazard of four feet or more.

(b) Employees will not be required to wear personal fall protection systems while riding on a standard lift chair while seated in the normal riding position.

(2) Ski lift facilities and structures. Personal fall arrest systems or personal fall restraint systems must be used when working at unprotected elevated locations. Exception to this requirement must only be permitted for emergency rescue or emergency inspection if a personal fall arrest system is not immediately available. Required personal protective equipment must be made available as quickly as possible.

(3) Guardrails on ski lift aerial work platforms.

(a) The platform must be equipped with standard height and strength guardrails where such guardrails will pass through the configuration of all lifts on which it is intended to be used.

(b) Where guardrails must be less than 39 inches high in order to clear carriages, guidage, etc., guardrails must be as high as will clear the obstructions but never less than 12 inches high.

(c) If the work platform is equipped with an upper work level, the upper level platform must be equipped with a toeboard at least four inches high.

(d) Each platform must be equipped with a lanyard attachment ring for each permissible occupant to attach a personal fall arrest system or personal fall restraint system.

(e) Each lanyard attachment ring must be of such strength as to sustain 5,400 pounds of static loading for each occupant permitted to be attached to a specific ring.

(f) Attachment rings must be permanently located as close to the center balance point of the platform as is practical.

(g) The rings may be movable, for instance, up and down a central suspension rod, but must not be completely removable.

(4) Work platform use.

(a) Passengers must be provided with and must use the correct personal fall arrest system or personal fall restraint system for the intended work.

(b) Any time a passenger's position is not protected by a standard guardrail at least 39 inches high, the individual must be protected by a personal fall restraint system, which will not permit free-fall over the platform edge.

(c) When personnel are passengers on a work platform and their work position requires the use of a personal fall arrest or personal fall restraint system, the lanyard must be attached to the work platform, not to the haulrope or tower.

All specifications would be in accordance with WAC 296-880-400.

Additional requirements for ski area facilities and operations can be found in chapter 296-59 WAC, Safety standard for ski area facilities and operations.

PDF296-880-400

Fall protection system specifications.

This section applies to all fall protection systems under the scope of this chapter unless specifically addressed in WAC 296-880-300.

PDF296-880-40005

Guardrail systems.

Guardrail systems and their use must conform to the following provisions: