Chapter 296-806 WAC

Last Update: 1/21/20MACHINE SAFETY

WAC Sections

| HTMLPDF | 296-806-099 | Definitions. |

| HTMLPDF | 296-806-100 | Scope. |

| HTMLPDF | 296-806-200 | Requirements for all machines. |

| HTMLPDF | 296-806-20002 | Secure machines designed to stay in one place. |

| HTMLPDF | 296-806-20004 | Protect employees from slipping hazards around machinery. |

| HTMLPDF | 296-806-20006 | Arrange work areas to avoid creating hazards. |

| HTMLPDF | 296-806-20007 | Machine controls and operations. |

| HTMLPDF | 296-806-20008 | Make sure operating controls meet these requirements. |

| HTMLPDF | 296-806-20010 | Protect employees from unintentional machine operation. |

| HTMLPDF | 296-806-20012 | Make sure emergency stop controls meet these requirements. |

| HTMLPDF | 296-806-20014 | Control machine vibration. |

| HTMLPDF | 296-806-20016 | Prevent overspeed conditions. |

| HTMLPDF | 296-806-20018 | Make sure hand feeding and retrieval tools meet these requirements. |

| HTMLPDF | 296-806-20020 | Protect employees who are adjusting or repairing machinery. |

| HTMLPDF | 296-806-20021 | Power transmission parts. |

| HTMLPDF | 296-806-20022 | Keep power transmission equipment in good working condition. |

| HTMLPDF | 296-806-20024 | Inspect power transmission parts. |

| HTMLPDF | 296-806-20026 | Protect employees lubricating moving machinery. |

| HTMLPDF | 296-806-20027 | Safeguarding requirements. |

| HTMLPDF | 296-806-20028 | Safeguard employees from the point of operation. |

| HTMLPDF | 296-806-20030 | Safeguard employees from nip or shear point hazards. |

| HTMLPDF | 296-806-20032 | Safeguard employees from rotating or revolving parts. |

| HTMLPDF | 296-806-20034 | Safeguard employees from reciprocating or other moving parts. |

| HTMLPDF | 296-806-20036 | Safeguard employees from flying objects. |

| HTMLPDF | 296-806-20038 | Safeguard employees from falling objects. |

| HTMLPDF | 296-806-20040 | Safeguard employees from moving surfaces with hazards. |

| HTMLPDF | 296-806-20041 | Safeguarding methods. |

| HTMLPDF | 296-806-20042 | Make sure guards meet these requirements. |

| HTMLPDF | 296-806-20043 | Devices. |

| HTMLPDF | 296-806-20044 | Make sure devices meet these requirements. |

| HTMLPDF | 296-806-20046 | Make sure light curtains meet these requirements. |

| HTMLPDF | 296-806-20048 | Make sure pressure-sensitive mats meet these requirements. |

| HTMLPDF | 296-806-20050 | Make sure restraint or pullback devices meet these requirements. |

| HTMLPDF | 296-806-20052 | Make sure two-hand devices meet these requirements. |

| HTMLPDF | 296-806-20054 | Make sure devices used with barrier guards meet these requirements. |

| HTMLPDF | 296-806-20055 | Distance. |

| HTMLPDF | 296-806-20056 | Make sure safeguarding by distance meets these requirements. |

| HTMLPDF | 296-806-20058 | Make sure guardrails used for safeguarding meet these requirements. |

| HTMLPDF | 296-806-300 | Requirements for specific machine hazards. |

| HTMLPDF | 296-806-30002 | Fit arbors and mandrels to the machine. |

| HTMLPDF | 296-806-30004 | Safeguard belt and rope drives. |

| HTMLPDF | 296-806-30006 | Make sure belt or rope drives meet these requirements. |

| HTMLPDF | 296-806-30008 | Protect employees while shifting belts on belt and pulley drives. |

| HTMLPDF | 296-806-30010 | Make sure belt tighteners meet these requirements. |

| HTMLPDF | 296-806-30012 | Safeguard cams, connecting rods, tail rods, and extension piston rods. |

| HTMLPDF | 296-806-30014 | Safeguard chain and sprocket drives. |

| HTMLPDF | 296-806-30016 | Safeguard fan blades. |

| HTMLPDF | 296-806-30017 | Flywheels. |

| HTMLPDF | 296-806-30018 | Safeguard flywheels. |

| HTMLPDF | 296-806-30020 | Safeguard gears. |

| HTMLPDF | 296-806-30022 | Safeguard projections on moving parts. |

| HTMLPDF | 296-806-30024 | Safeguard pulleys. |

| HTMLPDF | 296-806-30026 | Make sure pulleys meet these requirements. |

| HTMLPDF | 296-806-30028 | Safeguard revolving drums, barrels, and containers. |

| HTMLPDF | 296-806-30030 | Safeguard shafting. |

| HTMLPDF | 296-806-30032 | Make sure shafting meets these requirements. |

| HTMLPDF | 296-806-30034 | Safeguard unused keyways. |

| HTMLPDF | 296-806-30036 | Make sure revolving collars meet these requirements. |

| HTMLPDF | 296-806-30038 | Safeguard counterweights. |

| HTMLPDF | 296-806-400 | Additional requirements for some machines and machine operations. |

| HTMLPDF | 296-806-405 | Abrasive wheels. |

| HTMLPDF | 296-806-40502 | Make sure abrasive wheels and machines are properly designed and constructed. |

| HTMLPDF | 296-806-40504 | Make sure machines have safety guards. |

| HTMLPDF | 296-806-40506 | Make sure safety guards meet specific requirements. |

| HTMLPDF | 296-806-40508 | Provide a tongue guard on bench, pedestal, floorstand, and cylindrical grinders. |

| HTMLPDF | 296-806-40510 | Use a work rest for off-hand grinding. |

| HTMLPDF | 296-806-40511 | Mounting abrasive wheels. |

| HTMLPDF | 296-806-40512 | Make sure abrasive wheels are safe to use. |

| HTMLPDF | 296-806-40514 | Mount wheels properly. |

| HTMLPDF | 296-806-40516 | Use proper flanges. |

| HTMLPDF | 296-806-40518 | Make sure flanges are in good condition. |

| HTMLPDF | 296-806-40520 | Use specific flanges for Type 1 cutting-off wheels. |

| HTMLPDF | 296-806-40522 | Use specific flanges for Type 27A cutting-off wheels. |

| HTMLPDF | 296-806-40524 | Use blotters when required. |

| HTMLPDF | 296-806-40526 | Meet specific blotter requirements when using modified Types 6 and 11 wheels (terrazzo). |

| HTMLPDF | 296-806-410 | Calenders. |

| HTMLPDF | 296-806-41002 | Provide calender safety controls. |

| HTMLPDF | 296-806-41004 | Follow these stopping limit requirements for calenders. |

| HTMLPDF | 296-806-415 | Compactors. |

| HTMLPDF | 296-806-41502 | Safeguard hazardous moving parts of stationary compactors. |

| HTMLPDF | 296-806-41504 | Follow these requirements for compactor controls. |

| HTMLPDF | 296-806-41506 | Follow these requirements for compactor access doors and covers. |

| HTMLPDF | 296-806-41508 | Follow these requirements for compactors that cycle automatically. |

| HTMLPDF | 296-806-420 | Conveyors. |

| HTMLPDF | 296-806-42002 | Follow these requirements for conveyors. |

| HTMLPDF | 296-806-42004 | Provide emergency stops on conveyors. |

| HTMLPDF | 296-806-42006 | Label conveyor controls. |

| HTMLPDF | 296-806-42008 | Prohibit riding on conveyors. |

| HTMLPDF | 296-806-42010 | Provide safe access to conveyors. |

| HTMLPDF | 296-806-42012 | Provide backstop or antirunaway devices on incline, decline, or vertical conveyors. |

| HTMLPDF | 296-806-42014 | Make only safe alterations to conveyors. |

| HTMLPDF | 296-806-42016 | Inspect and replace worn conveyor parts. |

| HTMLPDF | 296-806-42018 | Follow these requirements for replacing conveyor parts. |

| HTMLPDF | 296-806-42020 | Follow these requirements for spill guards. |

| HTMLPDF | 296-806-42022 | Provide pedestrian overpasses for conveyors. |

| HTMLPDF | 296-806-42024 | Guard openings to hoppers and chutes. |

| HTMLPDF | 296-806-42026 | Install guideposts. |

| HTMLPDF | 296-806-42027 | Belt conveyors. |

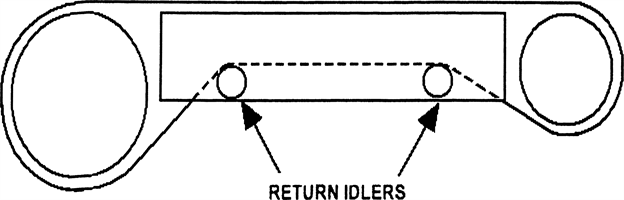

| HTMLPDF | 296-806-42028 | Guard nip points on belt conveyors. |

| HTMLPDF | 296-806-42030 | Install emergency stop controllers on overland belt conveyors. |

| HTMLPDF | 296-806-42032 | Install belt conveyor overpasses. |

| HTMLPDF | 296-806-42033 | Chain converyors. |

| HTMLPDF | 296-806-42034 | Safeguard chain conveyors. |

| HTMLPDF | 296-806-42036 | Guard return strands on chain conveyors. |

| HTMLPDF | 296-806-42038 | Guard chain conveyors that are used as a transfer mechanism. |

| HTMLPDF | 296-806-42039 | Elevator conveyors. |

| HTMLPDF | 296-806-42040 | Prevent material from falling off of elevator conveyors. |

| HTMLPDF | 296-806-42041 | Inclined reciprocating conveyors (shakers). |

| HTMLPDF | 296-806-42042 | Provide protection where employees must load shakers. |

| HTMLPDF | 296-806-42044 | Provide grating over silo and bunker openings for shuttle conveyors. |

| HTMLPDF | 296-806-42045 | Mobile conveyors. |

| HTMLPDF | 296-806-42046 | Guard wheels and rails on mobile conveyors. |

| HTMLPDF | 296-806-42048 | Prevent hazardous motion on mobile conveyors. |

| HTMLPDF | 296-806-42050 | Provide a detector for mobile conveyors. |

| HTMLPDF | 296-806-42052 | Provide safe access on mobile conveyors. |

| HTMLPDF | 296-806-42053 | Push-bar conveyors. |

| HTMLPDF | 296-806-42054 | Guard pusher-bar conveyors. |

| HTMLPDF | 296-806-42055 | Roller conveyors. |

| HTMLPDF | 296-806-42056 | Prohibit walking on roller-type conveyors. |

| HTMLPDF | 296-806-42058 | Use speed controls for roller and wheel conveyors. |

| HTMLPDF | 296-806-42060 | Safeguard belt-driven live roller conveyors. |

| HTMLPDF | 296-806-42061 | Screw conveyors. |

| HTMLPDF | 296-806-42062 | Guard screw conveyors. |

| HTMLPDF | 296-806-42063 | Skip hoists. |

| HTMLPDF | 296-806-42064 | Provide slack-cable switches on hoists. |

| HTMLPDF | 296-806-42066 | Block the skip bucket and counterweight guides. |

| HTMLPDF | 296-806-42068 | Protect against wire rope coming off sheaves. |

| HTMLPDF | 296-806-42069 | Slat and roller-slat conveyors. |

| HTMLPDF | 296-806-42070 | Safeguard slat and roller-slat conveyors. |

| HTMLPDF | 296-806-42071 | Towed conveyors. |

| HTMLPDF | 296-806-42072 | Provide a safe method for disengaging the tow pin. |

| HTMLPDF | 296-806-42074 | Protect employees from moving carts on towed conveyors. |

| HTMLPDF | 296-806-42076 | Provide clearances and warnings for carts on towed conveyors. |

| HTMLPDF | 296-806-42078 | Mark projections above the floor. |

| HTMLPDF | 296-806-425 | Food processing equipment. |

| HTMLPDF | 296-806-42502 | Provide locks on chamber doors of large air conditioning units. |

| HTMLPDF | 296-806-42504 | Use proper door locks on rack-type bread coolers. |

| HTMLPDF | 296-806-42506 | Provide see-through panels on fermentation room doors. |

| HTMLPDF | 296-806-42508 | Cover exposed hot pipes. |

| HTMLPDF | 296-806-42510 | Provide extension piping on stationary lubrication fittings. |

| HTMLPDF | 296-806-42512 | Provide hoods for pan-washing tanks. |

| HTMLPDF | 296-806-42514 | Safeguard proof boxes. |

| HTMLPDF | 296-806-42516 | Safeguard storage bins. |

| HTMLPDF | 296-806-42517 | Material handling. |

| HTMLPDF | 296-806-42518 | Follow these design requirements for bag lifts (bag arm elevators) and chutes. |

| HTMLPDF | 296-806-42520 | Follow these requirements for chain tackle. |

| HTMLPDF | 296-806-42522 | Safeguard conveyors. |

| HTMLPDF | 296-806-42524 | Use properly designed covers for screw conveyors (augers). |

| HTMLPDF | 296-806-42526 | Safeguard pallet jacks and hand trucks. |

| HTMLPDF | 296-806-42527 | Specific food processing equipment. |

| HTMLPDF | 296-806-42528 | Safeguard bakery slicers. |

| HTMLPDF | 296-806-42530 | Safeguard bakery wrapping machines. |

| HTMLPDF | 296-806-42532 | Provide troughs with antifriction-bearing casters. |

| HTMLPDF | 296-806-42534 | Follow these requirements for trough hoists and similar equipment. |

| HTMLPDF | 296-806-42536 | Follow these requirements for dividers. |

| HTMLPDF | 296-806-42538 | Safeguard manually-fed dough and cross-roll brakes. |

| HTMLPDF | 296-806-42540 | Provide a guard or tripping device on reversible dough brakes. |

| HTMLPDF | 296-806-42542 | Follow these requirements for doughnut machines. |

| HTMLPDF | 296-806-42544 | Follow these requirements for dumpbins and blenders. |

| HTMLPDF | 296-806-42546 | Follow these requirements for flour-handling machines. |

| HTMLPDF | 296-806-42548 | Follow these requirements for traveling or track-type flour scales. |

| HTMLPDF | 296-806-42550 | Follow these requirements for food grinders and cutters. |

| HTMLPDF | 296-806-42552 | Provide covers with interlocks on ingredient premixers, emulsifiers, and similar machines. |

| HTMLPDF | 296-806-42554 | Follow these requirements for open fat kettles. |

| HTMLPDF | 296-806-42556 | Follow these requirements for steam kettles. |

| HTMLPDF | 296-806-42558 | Follow these requirements for chocolate melting, refining, and mixing kettles. |

| HTMLPDF | 296-806-42560 | Safeguard meat-processing equipment (circular meat-cutting saws). |

| HTMLPDF | 296-806-42562 | Follow these requirements for horizontal dough mixers. |

| HTMLPDF | 296-806-42564 | Follow these requirements for vertical mixers. |

| HTMLPDF | 296-806-42566 | Follow these requirements for mechanical-feed moulders. |

| HTMLPDF | 296-806-42568 | Follow these requirements for hand-fed moulders. |

| HTMLPDF | 296-806-42570 | Design, install, and construct your ovens according to these requirements. |

| HTMLPDF | 296-806-42572 | Properly locate emergency "stop" buttons and main shut off valves for ovens. |

| HTMLPDF | 296-806-42574 | Inspect and test safety devices on ovens. |

| HTMLPDF | 296-806-42576 | Follow these requirements for peanut-cooling trucks. |

| HTMLPDF | 296-806-42578 | Follow these requirements for pretzel-rolling, pretzel stick extruding, rotary, and die machines. |

| HTMLPDF | 296-806-42580 | Safeguard box and roll-type dough sheeters. |

| HTMLPDF | 296-806-42582 | Provide proper enclosures for sifters. |

| HTMLPDF | 296-806-42584 | Follow these requirements for sugar and spice pulverizers. |

| HTMLPDF | 296-806-430 | Forging machines. |

| HTMLPDF | 296-806-43002 | Follow these safety requirements when using lead and lead casts. |

| HTMLPDF | 296-806-43004 | Properly inspect and maintain forging equipment. |

| HTMLPDF | 296-806-43006 | Use safety blocks on hammers and presses. |

| HTMLPDF | 296-806-43008 | Make sure tongs meet these requirements. |

| HTMLPDF | 296-806-43010 | Protect employees when removing scale. |

| HTMLPDF | 296-806-43012 | Provide adequate foundations for hammers and presses. |

| HTMLPDF | 296-806-43014 | Follow these requirements for manually operated valves and switches. |

| HTMLPDF | 296-806-43015 | Hammers. |

| HTMLPDF | 296-806-43016 | Use die keys and shims made of proper-grade material. |

| HTMLPDF | 296-806-43018 | Provide a safety cylinder head. |

| HTMLPDF | 296-806-43020 | Provide a shutoff valve. |

| HTMLPDF | 296-806-43022 | Provide a means for cylinder draining. |

| HTMLPDF | 296-806-43024 | Follow these requirements for pressure pipes. |

| HTMLPDF | 296-806-43026 | Follow these requirements when using board hammers. |

| HTMLPDF | 296-806-43027 | Other forge facility equipment. |

| HTMLPDF | 296-806-43028 | Protect against sparks from saws. |

| HTMLPDF | 296-806-435 | Garbage waste disposals. |

| HTMLPDF | 296-806-43502 | Safeguard garbage (waste) disposal equipment. |

| HTMLPDF | 296-806-440 | Glue spreaders. |

| HTMLPDF | 296-806-44002 | Provide guards and automatic shutoffs on glue spreaders. |

| HTMLPDF | 296-806-445 | Ironworkers. |

| HTMLPDF | 296-806-44502 | Safeguard ironworkers point of operation. |

| HTMLPDF | 296-806-44504 | Follow these requirements for adjustable restrictors when safeguarding ironworkers. |

| HTMLPDF | 296-806-450 | Lathes. |

| HTMLPDF | 296-806-45002 | Provide shields or guards on metal lathes for chip or coolant hazards. |

| HTMLPDF | 296-806-45004 | Safeguard work-holding devices (chucks). |

| HTMLPDF | 296-806-45006 | Follow these requirements for chip control and handling. |

| HTMLPDF | 296-806-45008 | Safeguard power-clamping devices. |

| HTMLPDF | 296-806-45010 | Restrain extended workpieces on horizontal lathes. |

| HTMLPDF | 296-806-45011 | Woodworking lathes. |

| HTMLPDF | 296-806-45012 | Guard cutting heads on profile lathes and swing-head lathes. |

| HTMLPDF | 296-806-45014 | Guard cutting heads on turning lathes. |

| HTMLPDF | 296-806-45016 | Guard automatic turning lathes. |

| HTMLPDF | 296-806-45018 | Guard wood lathes used for turning long pieces of stock. |

| HTMLPDF | 296-806-455 | Mechanical power presses. |

| HTMLPDF | 296-806-45502 | Make sure mechanical power presses are properly designed and constructed. |

| HTMLPDF | 296-806-45503 | Safeguarding. |

| HTMLPDF | 296-806-45504 | Safeguard presses that use unitized tooling. |

| HTMLPDF | 296-806-45506 | Protect operators from guidepost hazards. |

| HTMLPDF | 296-806-45508 | Safeguard the point of operation. |

| HTMLPDF | 296-806-45510 | Make sure point-of-operation guards are properly designed and constructed. |

| HTMLPDF | 296-806-45512 | Make sure barrier guards meet these requirements. |

| HTMLPDF | 296-806-45514 | Make sure point-of-operation devices are effective. |

| HTMLPDF | 296-806-45516 | Make sure presence-sensing devices used to safeguard the point of operation meet these requirements. |

| HTMLPDF | 296-806-45518 | Make sure pull-back devices used to safeguard the point of operation meet these requirements. |

| HTMLPDF | 296-806-45520 | Make sure restraint (holdout) devices used to safeguard the point of operation meet these requirements. |

| HTMLPDF | 296-806-45522 | Make sure two-hand control devices used to safeguard the point of operation meet these requirements. |

| HTMLPDF | 296-806-45524 | Make sure two-hand trip devices used to safeguard the point of operation meet these requirements. |

| HTMLPDF | 296-806-45526 | Provide additional safeguards when the operator puts one or both hands into the point of operation. |

| HTMLPDF | 296-806-45527 | Operations. |

| HTMLPDF | 296-806-45528 | Establish die setting procedures. |

| HTMLPDF | 296-806-45530 | Handle dies safely. |

| HTMLPDF | 296-806-45532 | Protect die setters during setup and tryout. |

| HTMLPDF | 296-806-45534 | Train press operators. |

| HTMLPDF | 296-806-45536 | Operate mechanical power presses safely. |

| HTMLPDF | 296-806-45538 | Provide tools and other means to protect press operators. |

| HTMLPDF | 296-806-45540 | Inspect and maintain presses. |

| HTMLPDF | 296-806-45542 | Make sure presses and operating practices used in the PSDI (presence sensing device initiation) mode of operation meet these requirements. |

| HTMLPDF | 296-806-460 | Mills. |

| HTMLPDF | 296-806-46002 | Meet height requirements for mill rolls. |

| HTMLPDF | 296-806-46004 | Provide mill safety controls. |

| HTMLPDF | 296-806-46006 | Follow these stopping limit requirements for mills. |

| HTMLPDF | 296-806-465 | Press brakes. |

| HTMLPDF | 296-806-46502 | Provide auxiliary safety aids on press brakes. |

| HTMLPDF | 296-806-46504 | Safeguard the point of operation on press brakes. |

| HTMLPDF | 296-806-46505 | Safe distance safeguarding. |

| HTMLPDF | 296-806-46506 | Follow this requirement when using safe distance safeguarding. |

| HTMLPDF | 296-806-46508 | Develop a safe distance safeguarding program for press brakes. |

| HTMLPDF | 296-806-46510 | Follow these requirements for safe distance training for press brakes. |

| HTMLPDF | 296-806-46512 | Require safe distance retraining for press brake operations. |

| HTMLPDF | 296-806-46514 | Conduct periodic safe distance inspections on press brakes. |

| HTMLPDF | 296-806-46516 | Supervise the safe distance program for press brakes. |

| HTMLPDF | 296-806-470 | Roll-forming and bending machines. |

| HTMLPDF | 296-806-47002 | Follow these requirements for machine initiation. |

| HTMLPDF | 296-806-47004 | Safeguard nip points of roll-forming and bending machines. |

| HTMLPDF | 296-806-475 | Sanding machines. |

| HTMLPDF | 296-806-47502 | Guard drum sanders. |

| HTMLPDF | 296-806-47504 | Guard disk sanders. |

| HTMLPDF | 296-806-47506 | Guard belt sanders. |

| HTMLPDF | 296-806-47508 | Follow these requirements for feed roll guarding. |

| HTMLPDF | 296-806-480 | Saws and cutting heads. |

| HTMLPDF | 296-806-48001 | General requirements for all saws and cutting heads. |

| HTMLPDF | 296-806-48002 | Protect employees using saws and cutting heads. |

| HTMLPDF | 296-806-48004 | Make sure saws and cutting heads are sharpened and tensioned by qualified people. |

| HTMLPDF | 296-806-48005 | General requirements for all saws. |

| HTMLPDF | 296-806-48006 | Make sure saws are safe to use. |

| HTMLPDF | 296-806-48007 | Requirements for all circular saws. |

| HTMLPDF | 296-806-48008 | Make sure all circular saws meet these requirements. |

| HTMLPDF | 296-806-48010 | Make sure circular saw gages meet these requirements. |

| HTMLPDF | 296-806-48012 | Safeguard hand-fed circular table saws. |

| HTMLPDF | 296-806-48014 | Provide kickback protection for employees using hand-fed circular table ripsaws when ripping wood products. |

| HTMLPDF | 296-806-48016 | Safeguard self-feed circular saws. |

| HTMLPDF | 296-806-48018 | Provide kickback protection for self-feed circular ripsaws when ripping wood products. |

| HTMLPDF | 296-806-48020 | Guard circular resaws. |

| HTMLPDF | 296-806-48022 | Provide spreaders for circular resaws. |

| HTMLPDF | 296-806-48023 | Requirements for specific circular saws. |

| HTMLPDF | 296-806-48024 | Protect employees from automatic saw hazards. |

| HTMLPDF | 296-806-48026 | Guard inverted swing (jump) saws. |

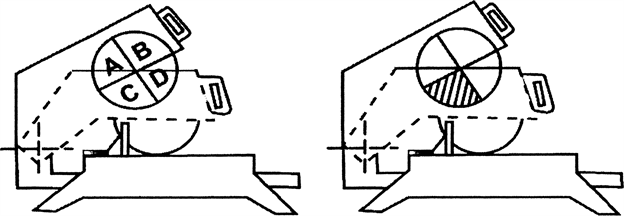

| HTMLPDF | 296-806-48028 | Guard miter saws. |

| HTMLPDF | 296-806-48030 | Guard radial saws. |

| HTMLPDF | 296-806-48032 | Limit the travel of radial saws. |

| HTMLPDF | 296-806-48034 | Provide kickback protection for radial saws used for ripping wood products. |

| HTMLPDF | 296-806-48036 | Guard revolving double arbor saws. |

| HTMLPDF | 296-806-48038 | Guard swing saws. |

| HTMLPDF | 296-806-48040 | Limit the travel of swing saws. |

| HTMLPDF | 296-806-48041 | Requirements for band saws and drag saws. |

| HTMLPDF | 296-806-48042 | Make sure band saws meet these requirements. |

| HTMLPDF | 296-806-48044 | Protect employees from drag saw hazards. |

| HTMLPDF | 296-806-48045 | General requirements for all cutting heads. |

| HTMLPDF | 296-806-48046 | Maintain and balance knives and cutting heads. |

| HTMLPDF | 296-806-48047 | Boring and mortising machines. |

| HTMLPDF | 296-806-48048 | Make sure boring and mortising machines meet these requirements. |

| HTMLPDF | 296-806-48049 | Chipper and hog mills. |

| HTMLPDF | 296-806-48050 | Follow these requirements for chipper mills. |

| HTMLPDF | 296-806-48052 | Follow these requirements for hog mills. |

| HTMLPDF | 296-806-48054 | Protect employees from falling into chipper and hog mills. |

| HTMLPDF | 296-806-48055 | Jointers. |

| HTMLPDF | 296-806-48056 | Make sure jointers with horizontal cutting heads meet these requirements. |

| HTMLPDF | 296-806-48058 | Guard horizontal cutting heads on hand-fed jointers. |

| HTMLPDF | 296-806-48060 | Guard vertical cutting heads on jointers. |

| HTMLPDF | 296-806-48061 | Molding, sticking and matching machines. |

| HTMLPDF | 296-806-48062 | Make sure molding, sticking and matching machines meet these requirements. |

| HTMLPDF | 296-806-48063 | Panel raisers and other similar machines. |

| HTMLPDF | 296-806-48064 | Guard hand-fed panel raisers and other similar machines. |

| HTMLPDF | 296-806-48065 | Planers. |

| HTMLPDF | 296-806-48066 | Make sure planers with a horizontal cutting head meet these requirements. |

| HTMLPDF | 296-806-48068 | Guard planers. |

| HTMLPDF | 296-806-48070 | Guard planer feed rolls. |

| HTMLPDF | 296-806-48072 | Provide kickback protection on planers running stock of varied thicknesses. |

| HTMLPDF | 296-806-48073 | Shapers. |

| HTMLPDF | 296-806-48074 | Make sure shapers meet these requirements. |

| HTMLPDF | 296-806-48075 | Tenoning machines. |

| HTMLPDF | 296-806-48076 | Guard tenoning machine feed chains and sprockets. |

| HTMLPDF | 296-806-48078 | Guard tenoning machines. |

| HTMLPDF | 296-806-48079 | Veneer machines. |

| HTMLPDF | 296-806-48080 | Guard veneer cutters and wringer knives. |

| HTMLPDF | 296-806-48082 | Guard veneer clippers. |

| HTMLPDF | 296-806-48084 | Follow these requirements for guarding guillotine cutters. |

| HTMLPDF | 296-806-48086 | Provide mechanisms to stop power-driven guillotine cutters. |

| HTMLPDF | 296-806-48088 | Prohibit riders on veneer slicer carriages. |

| HTMLPDF | 296-806-485 | Sewing machines. |

| HTMLPDF | 296-806-48502 | Guard sewing machine needles. |

DISPOSITION OF SECTIONS FORMERLY CODIFIED IN THIS TITLE

| 296-806-500 | Definitions. [Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. WSR 04-14-028, § 296-806-500, filed 6/29/04, effective 1/1/05.] Repealed by WSR 15-24-102, filed 12/1/15, effective 1/5/16. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. |

PDF296-806-099

Definitions.

Abrasive wheel. A grinding tool consisting of bonded abrasive grains. This includes diamond and reinforced wheels.

Adjustable barrier guard. A barrier guard with provisions for adjustment to accommodate various jobs or tooling set-ups.

Air-lift hammer. A type of gravity drop hammer in which the ram is raised for each stroke by an air cylinder. Because the length of stroke can be controlled, ram velocity, and therefore the energy delivered to the work piece, can be varied.

Antirepeat. A device that limits the machine to a single stroke if the activating means is held in the operative position.

Arbor. A rotating shaft used for mounting and transmitting torque to a cutting tool.

Authorized person. Someone the employer has given the authority and responsibility to perform a specific assignment.

Awareness barrier. A barrier device that allows more access to the hazard area, but still restricts access enough to warn of an approaching hazard.

Barricade. A barrier such as a guardrail, fence, or other framework designed to prevent employee access and exposure to a hazard.

Barrier guard. A barrier that provides a physical restriction from a hazard.

Belt conveyors. An endless belt of any material, operating over suitable pulleys to move materials placed on the belt.

Belt pole. A device used in shifting belts on and off fixed pulleys on line or countershaft where there are no loose pulleys. Belt poles are sometimes called "belt shippers" or "shipper poles."

Belt shifter. A device for mechanically shifting belts from tight to loose idler pulleys or vice versa, or for shifting belts on cones of speed pulleys.

Bench grinder. A bench mounted off-hand grinding machine with either one or two wheels mounted on a horizontal spindle.

Bending. The application of stress concentrated at specific points to permanently turn, press or force from a straight, level or flat condition to a curved or angular configuration.

Blade. A replaceable tool having one or more cutting edges for shearing, notching or coping.

Blanking. To bypass a portion of the sensing field of a presence-sensing device. The purpose is to allow objects such as tooling, feed stock, and work pieces to pass through the sensing field without sending a stop signal to the controlled machine. There are two blanking modes: Fixed and floating.

Blind hole. A hole drilled in an object, such as an abrasive wheel, that does not go all the way through the object.

Blotter. A compressible disc or washer, usually of blotting paper, plastic, cardboard, or gasket material, that is used between the wheel and the flanges to evenly distribute flange pressure on the wheel.

Board hammer. A type of gravity drop hammer where wood boards attached to the ram are raised vertically by action of contrarotating rolls, and then released. Energy for forging is obtained by the mass and velocity of the freely falling ram and the attached upper die.

Bolster plate. Plate attached to the press bed having holes, T-slots, or other means for attaching the lower die or die shoe.

Brake. Mechanism for stopping or preventing motion.

Chain conveyor. A conveyor in which one or more chains (including those with paddles or bars attached to them) move the conveyor. Specific examples of chain conveyors include drag, rolling, pusher bar, pusher chain and sliding chain conveyors.

Channel blanking. A feature that allows a safety light curtain system to be programmed to ignore objects. Also called "fixed blanking."

Chipper. A machine that cuts material into chips.

Chuck. A revolving clamp-like device used for holding and driving the work piece.

Clutch. A mechanism to couple the flywheel to the crankshaft. When engaged, it allows the driving force to be transmitted to the press slide.

Comb. See feather board.

Concurrent. Occurring at the same time.

Cone pulley. A pulley having two or more steps in a conical shape for driving machinery.

Cone and plug wheels (Types 16, 17, 18, 18R, and 19). Abrasive wheels manufactured with blind hole threaded bushings. They may be used on all surfaces except the flat mounting surface. Specific characteristics of the different cone and plug wheels are:

(a) Type 16 cones have a curved side with a nose radius.

(b) Type 17 cones have straight sides with or without a nose radius.

(c) Type 18 and 18R plug wheels are cylindrical in shape with either a square or curved grinding end.

(d) Type 19 cone wheels are a combination of cone and plug shapes.

Control system. Sensors, manual input and mode selection elements, interlocking and decision-making circuitry, and output elements of the press-operating devices and mechanisms.

Coping-notching. Where the edge or periphery of the work piece is sheared.

Counterbalance. Mechanism used to balance or support the weight of the connecting rods, slide, and slide attachments.

Cutting-off wheels. Abrasive wheels used to cut material such as masonry, pipe, etc.

Cutting tool or saw blade. A tool used on a metal sawing machine.

Cycle. The complete movement of the ram from its starting position and return to that same starting position.

Dado. A straight-sided groove, perpendicular to the face of the work piece, having a width greater than the thickness of a single saw blade.

Device. A control or attachment that is any of the following:

(a) Restrains the operator from inadvertently reaching into the hazardous area.

(b) Prevents normal or hazardous operation if any part of an individual's body is inadvertently within the hazardous area.

(c) Automatically withdraws the operator's hands, if the operator's hands are inadvertently within the hazardous area during the hazardous portion of the machine cycle.

(d) Maintains the operator or the operator's hands during the hazardous portion of the machine cycle at a safe distance from the hazardous area.

Die or dies. Tooling used in a press for shearing, punching, forming, drawing, or assembling metal or other material.

Die enclosure guard. Guard attached to the die shoe or stripper in a fixed position.

Die setter. A person who installs or removes dies from the press, and makes the necessary adjustments so the tooling functions properly and safely.

Die setting. Process of installing or removing dies, and adjusting the dies, other tooling and the safeguarding guards or devices.

Die shoe. Plate or block that a die holder is mounted on. It functions primarily as a base for the complete die assembly and, if used, is bolted or clamped to the bolster plate or the face of the slide.

Die shut height. Actual or design dimension between the mounting surfaces of a die.

Divider. A machine that mechanically divides the dough into pieces of predetermined volume or weight.

Dough sheeter. See sheeter.

Dressed. When material is removed from the cutting surfaces of an abrasive wheel to expose new sharp cutting surfaces.

Drilling/boring machine. A single or multiple spindle machine that uses a rotating cylindrical tool such as a drill, a counterboring tool, and similar tools to produce a hole, blind hole, counterbore, countersink, and similar cavities in work pieces. A work support means is provided to feed the tool into the work piece or the work piece into the tool.

Dross. Waste product or impurities formed on the surface of molten metal.

Dump bin and blender. That part of the flour handling system where the containers of flour are emptied.

Face of the slide. Surface of the slide to which the punch or upper die is generally attached.

Feather board/comb. A work-guiding and hold-down device consisting of stock with a series of spring-like fingers along the edge, set and positioned at an angle to the work piece.

Feeding. Placing material in or removing it from the point of operation.

Fence. A device used to locate and guide a work piece relative to the cutting tool.

Fixed barricade. A guard attached to a fixed surface used to enclose a hazardous area and prevent employees from placing any part of their body into the point of operation.

Fixed barrier guard. A guard attached to the frame, bolster, or other surface to enclose all or part of the point of operation or other hazard area.

Fixed blade. A stationary blade having one or more cutting edges.

Fixed blanking. A feature that allows a safety light curtain system to be programmed to ignore objects. Also called "channel blanking."

Fixture/jig. A device used to locate, hold, or clamp one or more work pieces in a desired position.

Flanges. Collars, discs, or plates between or against which wheels are mounted. There are four types of flanges:

(a) Adaptor.

(b) Sleeve.

(c) Straight relieved.

(d) Straight unrelieved.

Floating blanking (floating window). A feature that allows a safety light curtain system to be programmed to ignore the interruption of one or two beams within the light curtain. This allows the feeding of an object through the defined area at any point along the length of the curtain without causing it to produce a stop signal.

Floorstand grinder. A floor mounted, off-hand grinding machine with one or two wheels mounted on a horizontal spindle. The wheels are normally twenty-four inches or thirty inches in diameter and used for snagging operations.

Forging. Metal formed to a desired shape by impact or pressure in hammers, forging machines (upsetters), presses, rolls, and related forming equipment.

(a) Forging hammers, counterblow equipment, and high-energy-rate forging machines impart impact to the work piece, while most other types of forging equipment impart squeeze pressure in shaping the stock.

(b) Some metals can be forged at room temperature, but the majority of metals are made more plastic for forging with heat.

(c) Forged or drop forged parts are much stronger than poured or cast parts from foundries.

Forging presses. A class of forging equipment where the shaping of metal between dies is performed by mechanical or hydraulic pressure and usually is accomplished with a single workstroke of the press for each die station.

Full revolution clutch. Type of clutch that, when engaged, cannot be disengaged until the press has completed a single cycle (stroke).

Gage. See miter gage.

Gap (throat). An opening or recess in the frame of the machine to permit positioning of material or work pieces.

Gate or movable barrier device. Safeguarding device that encloses the point of operation before press motion can be initiated.

Guard. A barrier that does at least one of the following:

(a) Prevents the hands or other body part from reaching through, over, under, or around the guard into the hazard area.

(b) Prevents objects or debris from falling onto or being ejected towards an employee.

Guard (abrasive wheels). An enclosure designed to restrain the pieces of an abrasive wheel and furnish protection to the operator if the wheel is broken during operation.

Guidepost. The pin attached to the upper or lower die shoe. It operates within the bushing on the opposing die shoe to maintain the alignment of the upper and lower dies.

Hazard. A condition that could cause physical harm to a person.

Hazard area. An area or space that poses an immediate or impending physical hazard.

Hog. A machine used for cutting or grinding slabs and other coarse residue from the mill.

Horizontal lathe. A turning machine in which the work piece revolves about a horizontal axis. While the work is revolving, it is being shaped by cutting tools working either parallel to the axis of the work or at an angle to the axis of the work.

Idler (pulley). A pulley or roller on a shaft that presses against or rests on a drive belt to guide it or take up slack.

Inch. Die setting mode that engages the driving clutch so a small portion of one cycle (stroke) occurs, depending upon the length of time the operator control is held actuated.

Indirect recirculating ovens. Ovens that are equipped with a gas-tight duct system, a furnace, and a circulating fan.

(a) Combustion gases are circulated through this enclosed system and mixed with fresh combustion gases generated by the burner in the combustion chamber.

(b) A vent or overflow removes a portion of the gases to make room for the fresh gases added by the burner.

(c) No unburned gases or products of combustion enter the baking chamber.

Interlocked barrier guard. Barrier attached to the press frame and interlocked with the press control system so the press stroke cannot be started normally unless the guard, or its hinged or movable sections, enclose the point of operation.

Inverted swing and jump saws. Saws with a saw blade starting position below the table, where the blade must travel through the horizontal plane of the tabletop to make the cut on the stock.

Ironworker. A machine with multiple workstations at which various operations may be performed singly or simultaneously, including but not limited to:

(a) Punching;

(b) Shearing;

(c) Notching;

(d) Coping; and

(e) Forming.

Jig. See fixture.

Jog. Die setting mode where intermittent motion is imparted to the slide by momentary operation of the drive motor after the flywheel is at rest and the clutch is engaged.

Jointer. A machine that has a cylindrical cutter head with more than one knife or cutting edge. It has an adjustable in-feed means of work support, or an adjustable cutter head or knives, as well as a fence or other work piece guide.

Jump saw. A machine that utilizes a means of work support and hold down, and has a powered arbor on an arm that pivots about a point located behind the saw arbor at approximately the same height. At rest position the saw blade is below the work piece. See inverted swing and jump saws.

Kerf. The slot made by a saw blade as it saws through a work piece.

Kickback. The uncontrolled propulsion or self-feed type action of a work piece in the direction of the rotation or travel of the working portion of the saw, cutting tool, sanding belt, or sanding head.

Live roller conveyor. A series of rollers with objects moving over them through power to all or some of the rollers. The power is usually transmitted by a belt or chain.

Mandrel. Tooling or a machine component used to provide internal support. It can be a spindle or shaft on which a tool is mounted, such as a drill bit.

Manlift. A device consisting of a power-driven endless belt moving in one direction only, and provided with steps or platforms and handholds attached to it for the transportation of personnel from floor to floor.

Manual feeding. The operator puts material or the part being processed into the press for each cycle (stroke).

Maximum exposure angle. The largest part of a wheel that does not need to be covered by a safety guard.

Miter gage. A device used as a work piece pusher, guided by a table groove.

Miter saw. A cutoff saw with a means of work support. It utilizes a powered arbor on an arm that pivots about a point located behind the saw arbor at approximately the same height. The saw arbor may also slide vertically. In the at-rest position, the saw blade is above the maximum capacity work piece.

Mode. The state or condition of the control system that allows specific operations of the machine.

Modified Types 6 and 11 wheels (terrazzo). Similar to Type 6 "straight cup" wheels and Type 11 "flaring cup" wheels except for the bottom of the cup. The bottom of the cup is flat in Type 6 and 11 wheels. The modified wheels have bottoms that are sloped downwards towards the mounting hole. These modified wheels need to be mounted using a special tapered flange furnished by the tool manufacturer. These wheels are used in the terrazzo trade.

Molding machine. A machine that uses more than one arbor-mounted cylindrical, rotating cutting tool. It also uses power feeding, where once a work piece is engaged, it carries the work piece linearly through the balance of the intended operations, without further operator action. Operations can be performed on all surfaces of a work piece. Work pieces can be hopper- or hand-loaded and are fed ribbon-style into the machine.

Mortiser. A machine designed to produce a square or rectangular cavity through use of a moving, forming, or reciprocating tool. Means are provided to clamp and support the stock, and either move the stock into the tool or the tool into the stock.

Moulder. A machine in which the dough pieces are shaped and formed prior to final proofing.

Mounted wheels. Bonded abrasive wheels of various shapes, usually two inches diameter or smaller, that are secured to plain or threaded steel shafts or mandrels.

Movable barrier device. See gate or movable barrier device.

Nip-point belt and pulley guard. A guard that encloses the pulley and has rounded or rolled edge slots for the belt to pass through.

Off-hand grinding. Grinding of a work piece that is held in the operator's hand.

Overland conveyor. A single or series of belt conveyors designed to carry bulk material long distances, usually following the general contour of the land.

Part revolution clutch. Type of clutch that can be disengaged before the press slide completes a full stroke.

Pedestal grinder. An off-hand grinding machine similar to a bench grinder mounted on or otherwise attached to a floor-mounted pedestal.

Pinch point. Any point, other than the point of operation, where it is possible for a part of the body to be caught between moving parts or between a moving part and stationary one.

Planer. A machine with at least one cylindrical cutter head, that includes one or more inserted knife or cutting edge. A planer has a cutter head mounted over a means of work support. It also uses either an adjustable work support or cutter head to size the stock. The work piece is usually power-fed.

Point of operation. The area on a machine where work is actually performed upon the material being processed.

Power-driven hammers. Types of drop hammers in which the ram is raised for each stroke by a double-action steam, air, or hydraulic cylinder, and the energy delivered to the work piece is supplied by the velocity and weight of the ram and attached upper die driven downward by steam, air, or hydraulic pressure. Energy delivered during each stroke may be varied.

Power transmission parts. The mechanical components of a piece of equipment that, together with a source of power (sometimes referred to as a prime mover), provide the motion to a part of a machine or piece of equipment.

Presence-sensing device. A device that creates a sensing field, area, or plane to detect the presence of an individual or object.

Presence-sensing device initiation (PSDI). Operating mode of a mechanical power press where a single cycle (stroke) is initiated by a presence-sensing device when it senses that the operator has finished feeding or removing parts and all parts of the operator's body are withdrawn from the sensing field of the device.

Pull-back device. A device attached to the operator's hands and connected to the upper die or slide of the press that will pull the operator's hands out of the point of operation as the dies close.

Push block. A nonmetallic device with one or more handles. A push block also has a flat bottom surface with either a heel or friction material on it, used as a hold-down and feed device. The purpose of this is to provide a safe distance between the hands and the cutting tool.

Pusher-bar conveyor. Two endless chains cross-connected at intervals by bars or pushers that propel the load along the bed or trough.

Push stick. A nonmetallic stick shaped device designed to provide a safe distance between the hands and the cutting tool. It has, as part of its design, a notched end with a heel and toe to hold down and feed the work piece past the cutting tool.

Racks. Carriers of pans, panned dough and bakery products. They are usually constructed of metal and mounted on casters or provided with trolleys for use on a monorail system.

Reinforced wheels. Organic bonded abrasive wheels which have webbing, fabric or filament to provide resistance to complete breaking of the wheel should it become cracked or damaged.

Repeat. An unintended or unexpected successive stroke of the press resulting from a malfunction.

Restraint device. A device with attachments for the operator's hands and wrists that prevent the operator from reaching into the hazardous area.

Return-belt idlers. A roller that supports the return run of the conveyor belt.

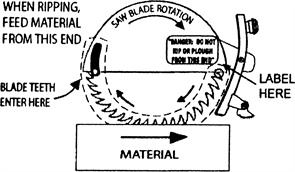

Ripping. A sawing operation made through the thickness of the work piece with the grain of natural wood, along the long dimension of a rectangular work piece, and usually parallel to that edge on reconstituted wood products. Two or more pieces result from the operation.

Rivet-making machines. The same as upsetters and bolt-headers when producing rivets with stock diameter of one inch or more.

Riving knife. See spreader.

Safeguarding by distance. Employees are kept far enough from a hazard that they will not contact or be injured by the hazard.

Safeguarding by location. Because of its location, no employee can inadvertently come in contact with a hazard during operation, maintenance, or servicing.

Safeguarding device. See device.

Safety block. A prop inserted between the upper and lower dies or between the bolster plate and the face of the slide to prevent the slide from falling of its own weight.

Safety cylinder. This safety device may be of the direct cushion type integral with the main cylinder or it may be of the separate cushion type whereby a constant supply of live steam or air is applied behind a separate piston adjacent to the main cylinder. A spring, suitably constrained, may also be employed.

Safety cylinder head. An air cushion at the top of the hammer, just below the head, to protect the head from damage by the piston.

Scale. Any layer or leaf of metal resembling the scale of a fish in size and thinness; such as a scale of iron.

Screw conveyor. A screw or auger that revolves in a suitably shaped trough or casing, used to move material in one specific direction.

SFPM. See surface feet per minute.

Shaper. A machine that uses one or more vertical spindles that are either fixed or able to be tilted, usually with an arbor mounted rotating cylindrical cutter, to form decorative or functional forms on a manually or power-fed work piece. The work piece is supported on a stationary or moving table. A guide, fixture, or template is used to control the operation. The spindle can be mounted above or below the work support means.

Sheeter. A machine that forms dough into a sheet by compression through one or more sets of driven rolls.

Sifter. A device that sifts flour. Sifter types are brush, oscillating, or vibrating.

Single stroke mechanism. Used on a full revolution clutch to limit the travel of the slide to one complete stroke at each engagement of the clutch.

Slat and roller slat conveyor. A conveyor employing one or more endless chains to which nonoverlapping, noninterlocking, spaced slats are attached.

Slide. Part of the press that moves back and forth in a straight line. Also called a ram, plunger, or platen.

Snagging. Grinding which removes relatively large amounts of material without regard to close tolerances or surface finish.

Spreader. A flat metal device slightly narrower than the saw kerf. It is designed to prevent the saw blade kerf in the work piece from closing on the sides of the blade during a sawing operation.

Steam hammers. A type of drop hammer where the ram is raised for each stroke by a double-action steam cylinder and the energy delivered to the work piece is supplied by the velocity and weight of the ram and attached upper die driven downward by steam pressure. Energy delivered during each stroke may be varied.

Stripper. A mechanism or die part for removing parts or material from the punch.

Surface feet per minute (SFPM). A measure of the speed of a point on the periphery (outer edge) of an abrasive wheel. It is calculated using the formula:

SFPM = .262 x diameter of the wheel (in inches) x RPM (revolutions per minute)

Example:

Wheel diameter = 24 inches

Spindle speed = 1000 RPM

SFPM = .262 x 24 x 1000 = 3,144 SFPM

Sweep device. A single or double arm (rod) attached to the upper die or slide of the press that is designed to move the operator's hands to a safe position as the dies close. Sweep devices are not allowed for point-of-operation safeguarding.

Swing saw/overhead swing cutoff saw. A machine with a means of work support using a powered arbor and circular saw blade that pivots about a point located above the saw arbor.

Tenoning machine. A machine designed to use two or more cylindrical cutters, or one or two circular saws, to size or prepare (or both) the ends of a work piece. The work piece is supported on a table or conveying means. A means for clamping the work piece is provided.

Terrazzo. A material of stone chips, such as marble, set in mortar and polished.

Threaded hole wheels. Abrasive wheels that have one central threaded bushing, securely anchored in place. They are mounted by being screwed onto a threaded machine spindle so that the wheel back seats firmly against an unrelieved flat back flange.

Tongs. Metal holder used to handle hot or cold forgings.

Tongue guard. An integral part of a safety guard that is located where the upper exposed part of the abrasive wheel meets the safety guard. It can be adjusted as necessary to maintain a set distance from the constantly decreasing diameter of the wheel.

Tooling. Elements for guiding or imparting a desired configuration to the material.

Top grinding. Grinding done above the horizontal centerline of the wheel.

Towed conveyor. An endless chain supported by trolleys from an overhead track or running in a track on the floor with means for towing floor-supported trucks, dollies, or carts.

Trimming presses. A class of auxiliary forging equipment that removes flash (metal splash) or excess metal from a forging. This trimming operation can also be done cold, as in can coining, a product-sizing operation.

Trip (or tripping). Momentary actuation of the activating control to initiate the cycle (stroke).

Trued. When the cutting surfaces of an abrasive wheel have been reshaped to expose new sharp cutting surfaces.

Turnover bar. A bar used in die setting to manually turn the crankshaft of the press.

Two-hand device. A device that requires the concurrent use of both of the operator's hands to both initiate and continue the machine cycle during the hazardous portion of the machine cycle.

Two-hand trip device. A device that requires concurrent operation of the trip controls or levers by the operator's hands to initiate the machine cycle.

Type A movable gate. A device that encloses the hazardous area when the machine cycles and does not open until the end of the cycle.

Type B movable gate. A device that encloses the hazardous area when the machine cycles and opens when hazardous motion of the cycle is over. Type B devices are not allowed on full revolution type machinery.

Type 1 wheel. An abrasive wheel shaped like a disc with a mounting hole in the middle. Sometimes called a "straight wheel." It has diameter (D), thickness (T), and hole size (H) dimensions. Grinding is normally done on the periphery (outside curve) of the wheel (T dimension). Can be used for grinding, cutting-off, and tuck pointing.

Type 2 wheel. An abrasive wheel shaped like an open-ended, hollow cylinder. Sometimes called a cylinder wheel. It has diameter (measured from the outer wall of the cylinder), wheel thickness (height of the cylinder), and rim thickness (thickness of the cylinder wall). Grinding is done on the end of the cylinder (rim thickness dimension).

Type 6 wheel. An abrasive wheel shaped like a straight-sided cup or bowl with a mounting hole in the bottom of the cup. Sometimes called a "cup wheel." It has diameter (D), thickness (T), hole size (H), rim thickness (W), and back thickness (E) dimensions. Grinding is normally done on the cup rim (W dimension).

Type 11 wheel. An abrasive wheel shaped like a cup or bowl with a mounting hole in the bottom of the cup. The sides of the cup are not straight-sided but are angled outward. Sometimes called a "flaring cup wheel" since the sides are "flared" out. It has double diameter dimensions (top D and bottom J). It also has thickness (T), hole size (H), rim thickness (W) and back thickness (E) dimensions. Grinding is normally done on the cup rim (W dimension).

Type 16, 17, 18, 18R, and 19 wheels. See cone and plug wheels.

Type 27 wheel. An abrasive wheel similar to a Type 1 wheel, but the center of the wheel around the mounting hole is pushed back (depressed). Sometimes called a "depressed center" wheel. It has diameter (D), thickness (U) and hole size (H) dimensions. The depressed center allows grinding on the flat surface of the wheel without interference from the flange or mounting hardware.

Type 27A cutting-off wheel. Similar to a Type 27 wheel. Specifically designed for use on cutting-off machines.

Type 28 wheel. An abrasive wheel similar to a Type 27 wheel, but the face of the wheel is angled upward and away from the mounting hole. The face of a Type 27 wheel is flat and perpendicular to the mounting hole. A Type 28 wheel is also called a "depressed center" wheel. It has diameter (D), thickness (U) and hole size (H) dimensions. The depressed center allows grinding without interference from the mounting. A Type 28 wheel has a saucer-shaped grinding rim and is designed for corner grinding and side grinding.

Type 29 wheel. An abrasive wheel that has reversed, saucer-shaped grinding rims (similar to a partially opened umbrella).

Unitized tooling. A die that has the upper and lower members incorporated into a self-contained unit that holds the die members in alignment.

Upsetters (or forging machines, or headers). A type of forging equipment, related to the mechanical press, in which the main forming energy is applied horizontally to the work piece that is gripped and held by prior action of the dies.

Wood products. Wood products include wood and reconstituted wood products that generate chips or dust in the processing of a wood piece.

PDF296-806-100

Scope.

Machines and their moving parts create the potential for workplace injuries. Installed and used properly safeguards can protect workers by helping to reduce or control machine hazards.

This chapter applies if you have machines or machine operations in your workplace. For requirements on hand-held tools go to Portable power tools, chapter 296-807 WAC.

PDF296-806-200

Requirements for all machines.

Summary

This section applies to all machines in your workplace. It is organized into the following four categories:

(1) General requirements.

(2) Safeguarding requirements.

(3) Safeguarding methods.

(4) Requirements for specific machine hazards.

Reference: | In addition to the requirements in this section, you need to refer to the following sections of this chapter in order to determine if additional requirements are listed for machines or operations in your workplace: |

1. Additional requirements for some machines and machine operations, WAC 296-806-400. | |

2. For requirements that apply to hand-held tools, see Portable power tools, chapter 296-807 WAC. |

Your responsibility:

To protect employees from machine hazards in your workplace.

GENERAL REQUIREMENTS

workplace

You must meet the requirements... | in this section: |

Secure machines designed to stay in one place | WAC 296-806-20002 |

Protect employees from slipping hazards around machinery | WAC 296-806-20004 |

Arrange work areas to avoid creating hazards | WAC 296-806-20006 |

PDF296-806-20002

Secure machines designed to stay in one place.

You must make sure machines designed to stay in one place are secured so they will not move or change position during use.

EXEMPTION: | Machines that have either rubber feet or foot pads made of nonskid (high coefficient of friction) or similar vibration dampening materials do not have to be secured as long as the machine will not tip, fall over, or walk (move). |

PDF296-806-20004

Protect employees from slipping hazards around machinery.

You must make sure employees working around dangerous machines are protected from slipping on smooth, oily, or otherwise slippery floors by providing one of the following types of floor covering:

(1) Nonslip matting.

(2) Grating.

(3) Nonslip composition flooring.

(4) Some other effective floor treatment.

Reference: | For additional requirements about housekeeping, personal protective equipment (PPE), and work practices, see the Safety and health core rules, chapter 296-800 WAC. |

PDF296-806-20006

Arrange work areas to avoid creating hazards.

(1) You must make sure work areas around machinery are designed with enough space so each operator:

(a) Can clean and handle material without interference from other workers or machines.

(b) Does not have to stand in the way of passing traffic.

(2) You must provide enough space so employees can bring in and remove materials safely.

Reference: | For requirements that apply to Aisles and passageways, see WAC 296-24-73505. |

PDF296-806-20007

Machine controls and operations.

You must meet the requirements… | in this section: |

Make sure operating controls meet these requirements | WAC 296-806-20008 |

Protect employees from unintentional machine operation | WAC 296-806-20010 |

Make sure emergency stop controls meet these requirements | WAC 296-806-20012 |

Control machine vibration | WAC 296-806-20014 |

Prevent overspeed conditions | WAC 296-806-20016 |

Make sure hand feeding and retrieval tools meet these requirements | WAC 296-806-20018 |

Protect employees who are adjusting or repairing machinery | WAC 296-806-20020 |

PDF296-806-20008

Make sure operating controls meet these requirements.

EXEMPTION: | This rule does not apply to constant pressure controls used only for setup. |

(1) You must make sure each machine has a control that both:

(a) Stops the machine; and

(b) Can be reached by the operator without leaving the operator's position.

(2) You must make sure the operator can easily reach all machine controls without reaching into a hazard area of the machine.

PDF296-806-20010

Protect employees from unintentional machine operation.

(1) You must make sure foot-operated controls are located or guarded so that unintentional movement to the "on" position is unlikely.

(2) You must make sure machines will not automatically restart when power is restored after a power failure, if restarting would create a hazard for employees.

Note: | Operating controls can be protected from unintentional movement by methods such as covers on foot treadles and collars around machinery start buttons. |

PDF296-806-20012

Make sure emergency stop controls meet these requirements.

You must make sure emergency stop controls, if required, meet all the following:

(1) Are red in color.

(2) Are easily reached from the operator's normal work position.

(3) Are kept in a good working condition.

(4) Have to be manually reset before a machine can be restarted.

PDF296-806-20014

Control machine vibration.

You must prevent excessive machine vibration that could create a hazard to employees.

PDF296-806-20016

Prevent overspeed conditions.

You must operate tools and equipment within their rated speed.

Note: | Actions that could cause an overspeed condition include: |

1. Installing a more powerful motor. | |

2. Changing or increasing the power source. | |

3. Changing attachment size or type, such as a blade or wheel. | |

The attachment speed (rpm) and motor speed (rpm) should match. |

PDF296-806-20018

Make sure hand feeding and retrieval tools meet these requirements.

You must make sure hand feeding and retrieval tools:

(1) Are suitable for the work to be done.

(2) Do not create a hazard when used.

(3) Are of a size and shape that will keep the operator's hands outside the hazardous area.

(4) Are constructed so they will not shatter if they come in contact with the machine tool or tooling.

Note: | Hand feeding and retrieval tools, such as push sticks or push blocks, can not be used instead of required safeguarding, unless a specific machine requirement allows it. |

PDF296-806-20020

Protect employees who are adjusting or repairing machinery.

EXEMPTION: | This rule does not apply if the machine has to be in motion to properly adjust it. |

You must make sure power-driven machinery is completely stopped before either:

(1) Making adjustments or repairs; or

(2) Removing material or refuse from the machine.

Reference: | For requirements about maintaining and servicing machinery where the unexpected start-up, energization, or release of stored energy could injure an employee are in Lockout/tagout (control of hazardous energy), chapter 296-803 WAC. |

PDF296-806-20021

Power transmission parts.

You must meet the requirements… | in this section: |

Keep power transmission equipment in good working condition | WAC 296-806-20022 |

Inspect power transmission parts | WAC 296-806-20024 |

Protect employees lubricating moving machinery | WAC 296-806-20026 |

PDF296-806-20022

Keep power transmission equipment in good working condition.

(1) You must make sure power transmission parts are kept in good working condition at all times.

(2) You must keep bearings free from lost motion and well lubricated.

PDF296-806-20024

Inspect power transmission parts.

You must inspect power transmission parts at least once every sixty days to make sure that all:

(1) Safeguarding meets the requirements of this chapter.

(2) Parts are in proper alignment.

(3) Bolts and screws that hold power transmission parts together or support the system are tight.

PDF296-806-20026

Protect employees lubricating moving machinery.

(1) You must protect employees who lubricate moving machinery by:

(a) Providing tools, such as oil cans or grease guns, that have spouts or necks that are long enough to keep the employees' hands out of hazardous areas.

(b) Requiring employees to wear closely fitted clothing.

Note: | Things such as clothing, hair, and jewelry can get caught in machinery and be a hazard on the job. |

(2) You must make sure drip cups and pans are securely fastened to the machinery.

PDF296-806-20027

Safeguarding requirements.

You must meet the requirements… | in this section: |

Safeguard employees from the point of operation | WAC 296-806-20028 |

Safeguard employees from nip or shear point hazards | WAC 296-806-20030 |

Safeguard employees from rotating or revolving parts | WAC 296-806-20032 |

Safeguard employees from reciprocating or other moving parts | WAC 296-806-20034 |

Safeguard employees from flying objects | WAC 296-806-20036 |

Safeguard employees from falling objects | WAC 296-806-20038 |

Safeguard employees from moving surfaces with hazards | WAC 296-806-20040 |

PDF296-806-20028

Safeguard employees from the point of operation.

Important:

If a specific safeguarding method in this chapter is required for machinery or machine parts found in your workplace, follow the specific requirement.

In the absence of a specific safeguarding method required by this or some other chapter, you need to choose a method or combination of methods from the safeguarding requirements found in Safeguarding methods, WAC 296-806-20042 through 296-806-20058. Examples of safeguarding methods include:

1. Guards.

2. Devices.

3. Safeguarding by distance.

4. Safeguarding by location.

You must protect employees from hazards created by the point of operation by using one or more safeguarding methods.

PDF296-806-20030

Safeguard employees from nip or shear point hazards.

You must protect employees from hazards created by nip or shear points by using one or more safeguarding methods.

PDF296-806-20032

Safeguard employees from rotating or revolving parts.

You must protect employees from hazards created by rotating or revolving parts by using one or more safeguarding methods.

PDF296-806-20034

Safeguard employees from reciprocating or other moving parts.

You must protect employees from hazards created by reciprocating or other moving parts by using one or more safeguarding methods.

PDF296-806-20036

Safeguard employees from flying objects.

You must protect employees from hazards created by flying objects, including chips, sparks, and fluids by using one or more safeguarding methods.

PDF296-806-20038

Safeguard employees from falling objects.

You must protect employees from hazards created by falling objects by using one or more safeguarding methods.

PDF296-806-20040

Safeguard employees from moving surfaces with hazards.

You must safeguard employees from hazards created by moving surfaces with hazards such as sharp edges, burrs, and protruding nails and bolts.

PDF296-806-20041

Safeguarding methods.

Guards

You must meet the requirements… | in this section: |

Make sure guards meet these requirements | WAC 296-806-20042 |

PDF296-806-20042

Make sure guards meet these requirements.

(1) You must make sure guards do not create additional hazards such as sharp edges or pinch points between the guard and moving machine parts.

(2) You must make sure guards are:

(a) Made of durable materials.

(b) Strong enough to withstand the forces to which they are exposed.

(c) Securely fastened to the machine, if possible, or to the building structure if they cannot be attached to the machine.

(3) You must make sure guards protect employees by doing both of the following:

(a) Preventing hands or other body parts from reaching through, over, under, or around the guard into the hazard area; and

(b) Preventing objects or debris from falling onto or being thrown towards an employee.

(4) You must make sure barrier guards:

(a) Are properly installed, adjusted, and maintained.

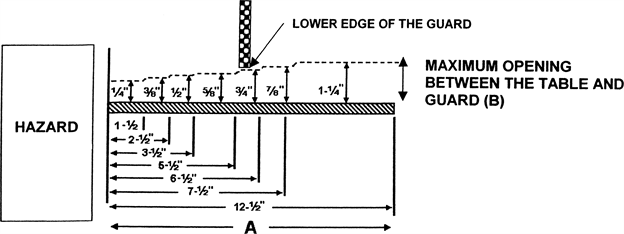

(b) Have no opening at any point larger than shown in Table 200-1, Largest Allowable Guard Opening.

Reference: | Metal cutting shears are allowed to be guarded with properly applied awareness barrier safeguarding as described in ANSI B11.4-1993, Sections 6.3.3. |

Table 200-1

Largest Allowable Guard Opening (inches)

If the distance (A) from hazard to the guard is: | Then the opening (B) in the guard or between the table and the guard can not be greater than: | ||

1/2 to 1 1/2 | 1/4 | ||

1 1/2 to 2 1/2 | 3/8 | ||

2 1/2 to 3 1/2 | 1/2 | ||

3 1/2 to 5 1/2 | 5/8 | ||

5 1/2 to 6 1/2 | 3/4 | ||

6 1/2 to 7 1/2 | 7/8 | ||

7 1/2 to 12 1/2 | 1 1/4 | ||

12 1/2 to 15 1/2 | 1 1/2 | ||

15 1/2 to 17 1/2 | 1 7/8 | ||

17 1/2 to 31 1/2 | 2 1/8 | ||

Over 31 1/2 | 6 | ||

This diagram illustrates the information found in Table 200-1. The size of the opening in the guard, or between the bottom edge of the guard and the feed table is small enough to prevent any part of the operator's body from reaching the hazardous area.

Illustration #1 - Distance from hazard to Guard (A)

|

PDF296-806-20043

Devices.

You must meet the requirements… | in this section: |

Make sure devices meet these requirements | WAC 296-806-20044 |

Make sure light curtains meet these requirements | WAC 296-806-20046 |

Make sure pressure-sensitive mats meet these requirements | WAC 296-806-20048 |

Make sure restraint or pullback devices meet these requirements | WAC 296-806-20050 |

Make sure two-hand devices meet these requirements | WAC 296-806-20052 |

Make sure devices used with barrier guards meet these requirements | WAC 296-806-20054 |

PDF296-806-20044

Make sure devices meet these requirements.

You must make sure devices used to safeguard employees do either of the following:

(1) Stop the motion of a moving part before an employee comes in contact with it and has to be manually reset before machines can be restarted; or

(2) Be designed and constructed to prevent the operator from having any part of their body in the danger zone during the hazardous part of the operating cycle.

Reference: | For more information on installation of safety devices, see Performance criteria for safeguarding, ANSI B11.19-2003. |

PDF296-806-20046

Make sure light curtains meet these requirements.

Important:

All devices must meet the general requirements for devices found in, Make sure devices meet these requirements, WAC 296-806-20044.

(1) You must make sure light curtains, when used:

(a) Respond to the presence of an operator's hand, other body part, or a work piece.

(b) Have indicators that are easily seen by the operator showing when the device is functioning or has been bypassed.

Note: | Even if a shiny reflective object or work piece is used with a light curtain or other electro-optical device, it should still respond to the operator's hand or other body part. |

(2) You must make sure only authorized persons can make the following adjustments to light curtains:

(a) Variations in operating conditions.

(b) Fixed or channel blanking.

(c) Floating blanking (sometimes referred to as floating channel or floating window features).

(3) You must safeguard access to the point of operation that is not protected by light curtains.

Reference: | For more information on light curtains and their requirements, see Performance criteria for safeguarding, ANSI B11.19-2003 |

PDF296-806-20048

Make sure pressure-sensitive mats meet these requirements.

Important:

All devices must meet the general requirements for devices found in, Make sure devices meet these requirements, WAC 296-806-20044.

You must make sure pressure-sensitive mats:

(1) Detect the presence or absence of the operator or others.

(2) Send the stop command and prevent successive machine cycles if any single component fails.

(3) Are connected with the machine control system so the device's stop signal immediately stops action of the machine tool and requires use of the start control before the machine can begin another cycle.

(4) Are located so that the operator cannot reach the recognized hazard before hazardous motion has stopped.

(5) Have an indicator easily seen by the operator that shows the mat is operating.

PDF296-806-20050

Make sure restraint or pullback devices meet these requirements.

Important:

All devices must meet the general requirements for devices found in, Make sure devices meet these requirements, WAC 296-806-20044.

You must make sure restraint or pullback devices:

(1) Prevent the operator from reaching into the point of operation or withdraw the operator's hands from the point of operation before motion of the machine creates a hazard.

(2) Have fasteners, pins, and other items used to secure and maintain the setting of the device applied in a way that minimizes loosening, slipping, or failure during use.

(3) Are worn inside gloves, if used, so if a glove becomes trapped inside a machine or tool, the device can still remove the operator's hand from the hazard area.

PDF296-806-20052

Make sure two-hand devices meet these requirements.

Important:

All devices must meet the general requirements for devices found in, Make sure devices meet these requirements, WAC 296-806-20044.

You must make sure two-hand devices:

(1) Protect each hand device against accidental operation.

(2) Require simultaneous operation of both hand devices to begin the cycle, including the first cycle (automatic mode).

(3) Are provided with an antirepeat feature when used in single cycle mode.

(4) Have a set of devices for each operator if more than one needs to be safeguarded.

(5) Are located far enough from the nearest hazard so the operator cannot reach the hazard before hazardous motion stops.

Reference: | For more information on proper installation of safety devices, see Performance criteria for safeguarding, ANSI B11.19-2003. |

PDF296-806-20054

Make sure devices used with barrier guards meet these requirements.

Important:

All devices must meet the general requirements for devices found in, Make sure devices meet these requirements, WAC 296-806-20044.

(1) You must make sure movable barrier devices:

(a) Return to the open position if they encounter an obstruction while enclosing the hazardous area.

(b) Are designed so the operator or others cannot reach the hazard by reaching over, under, around or through the device when it is in the closed position.

(2) You must make sure interlocks used with barrier guards do all of the following:

(a) Stop hazardous motion of machines when interlocks are open.

(b) Are not easily bypassed.

(c) Are designed and installed so that closing the interlocks will not cause a hazard to employees.

PDF296-806-20055

Distance.

You must meet the requirements… | in this section: |

Make sure safeguarding by distance meets these requirements | WAC 296-806-20056 |

Make sure guardrails used for safeguarding meet these requirements | WAC 296-806-20058 |

PDF296-806-20056

Make sure safeguarding by distance meets these requirements.

You must make sure means used to safeguard by distance do both of the following:

(1) Prevent parts or material from falling on employees below; and

(2) Separate employees on fixed ladders, stairs, floors, or other walking or working surfaces from the hazard by:

(a) More than seven feet vertically; or

(b) A horizontal distance that prevents employees from contacting or being injured by the hazard according to the distances in Table 200-2.

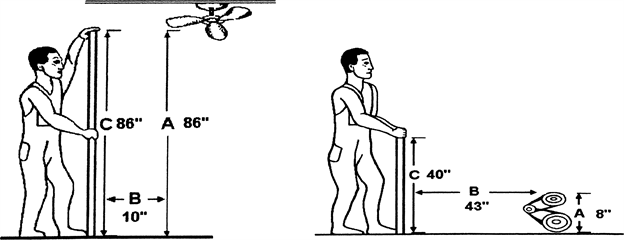

Table 200-2 helps you identify either the required horizontal distance from the hazard to the barricade (B), or the required height of the barricade (C), as long as you know A and either variable, B or C.

Table 200-2

Safe Distances for Fixed Barricades (B)

Height of the Hazard (A) | Height of the Barricade (C) | |||||||

96 | 86 | 78 | 71 | 63 | 55 | 48 | 40 | |

96 | 0 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

86 | . . . . | 10 | 14 | 16 | 20 | 20 | 24 | 24 |

78 | . . . . | . . . . | 14 | 20 | 24 | 28 | 36 | 43 |

71 | . . . . | . . . . | . . . . | 24 | 36 | 36 | 40 | 43 |

63 | . . . . | . . . . | . . . . | 20 | 36 | 36 | 40 | 51 |

55 | . . . . | . . . . | . . . . | 4 | 32 | 36 | 40 | 51 |

48 | . . . . | . . . . | . . . . | . . . . | 20 | 36 | 40 | 55 |

40 | . . . . | . . . . | . . . . | . . . . | 12 | 36 | 40 | 55 |

32 | . . . . | . . . . | . . . . | . . . . | . . . . | 24 | 36 | 51 |

24 | . . . . | . . . . | . . . . | . . . . | . . . . | . . . . | 20 | 48 |

16 | . . . . | . . . . | . . . . | . . . . | . . . . | . . . . | 12 | 48 |

8 | . . . . | . . . . | . . . . | . . . . | . . . . | . . . . | 8 | 43 |

Note: | The height and distance requirements of Table 200-2 are designed to safeguard workers from a fixed hazard. If a hazard involves flying chips, fluids, parts or materials, the barrier height, distance, and construction may need to be adjusted to provide adequate protection. |

Illustration 2 - How to measure variables for Table 2

|

Examples:

(1) If the height of the hazard (A) is seventy-eight inches, and the horizontal distance from the hazard to the barricade (B) is fourteen inches, the required height of the barricade (C) is seventy-eight inches.

(2) If the height of the hazard (A) is eighty-six inches, and the height of the barricade (C) is fifty-five inches, then the required horizontal distance from the hazard to the barricade (B) is twenty inches.

PDF296-806-20058