Chapter 204-76 WAC

Last Update: 1/7/14STANDARDS FOR BRAKE SYSTEMS

WAC Sections

| HTMLPDF | 204-76-010 | Promulgation. |

| HTMLPDF | 204-76-020 | Scope. |

| HTMLPDF | 204-76-030 | Definitions. |

| HTMLPDF | 204-76-040 | Straight air brakes. |

| HTMLPDF | 204-76-050 | Air over hydraulic brakes. |

| HTMLPDF | 204-76-060 | Vacuum assisted hydraulic brakes. |

| HTMLPDF | 204-76-070 | Hydraulic brakes. |

| HTMLPDF | 204-76-99001 | Bolt type brake chamber data. |

| HTMLPDF | 204-76-99002 | Clamp type brake chamber data. |

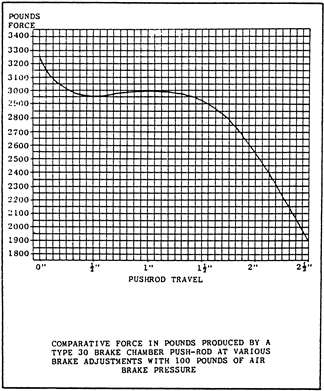

| HTMLPDF | 204-76-99003 | Push rod force vs. travel. |

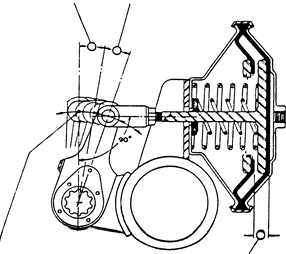

| HTMLPDF | 204-76-99004 | Relationship of push rod and slack adjuster angle to brake force. |

| HTMLPDF | 204-76-99005 | Air operated wedge brake adjustment. |

PDF204-76-010

Promulgation.

By authority of RCW 46.37.005, the state patrol hereby adopts the following rules relating to brake systems.

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-010, filed 1/7/14, effective 2/7/14; WSR 80-10-006 (Order 80-07-01), § 204-76-010, filed 7/25/80.]

PDF204-76-020

Scope.

These rules apply only to brake systems on vehicles with a gross vehicle weight rating of 10,000 pounds or more.

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-020, filed 1/7/14, effective 2/7/14; WSR 80-10-006 (Order 80-07-01), § 204-76-020, filed 7/25/80.]

PDF204-76-030

Definitions.

(1) "Air brake hose" means any flexible hose used as an integral part of a service or auxiliary (emergency stopping) air brake system, where flexibility in a connection is mandatory due to vehicle design and includes the service and emergency air hoses between vehicles in a combination of vehicles.

(2) "Air brake reservoir" means a storage container for compressed air.

(3) "Air compressor" means a device which compresses air used for actuation of the brakes and/or other components of the vehicle.

(4) "Air gauge" means a gauge usually mounted on the instrument panel which indicates the air pressure in the air reservoir tanks, brake application pressure, or other air system pressures.

(5) "Air governor" means a regulator which controls the supply of air pressure for the brake system, generally by controlling the air compressor cut-in and cut-out pressure within a preset range.

(6) "Air over hydraulic brake system" means a hydraulic type brake system actuated by an air-powered master cylinder.

(7) "Air pressure protection valve" means a unit through which air flow is prevented except when a preselected input pressure is exceeded.

(8) "Brake" means an energy conversion mechanism used to retard, stop, or hold a vehicle.

(9) "Brake assembly" means an assembly of brake parts, the components of which are determined according to the type or design of the brake system.

(10) "Brake cam" means a cam mounted on the camshaft and located between the ends of the brakeshoes. When rotated by the brake camshaft, the cam expands the brake-shoes against the brakedrum.

(11) "Brake camshaft" means the camshaft which is held to the vehicle axle housing or backing plate by bosses containing bronze or nylon bushings. Air pressure is converted into mechanical force by the brake chamber which is attached by a push rod to the slack adjuster. The slack adjuster multiplies the force by the lever principle and applies the force to the brakeshoes.

(12) "Brake chamber or actuator" means a unit in which a diaphragm converts pressure to mechanical force for actuation of the brakes.

(13) "Brake cylinder" means a unit in which a piston converts pressure to mechanical force for actuation of the brakes.

(14) "Brake master cylinder" means the primary unit for displacing hydraulic fluid under pressure in the brake system.

(15) "Brake pedal" means a foot-operated lever which, when actuated, causes the brake(s) to be applied.

(16) "Brakeshoe" means a rigid half-moon shaped device with friction material affixed to the outer surface. The brakeshoes are generally mounted on a backing plate and are located inside the brakedrum. When expanded by the brake mechanism, the brakeshoes press the brake lining against the brakedrum, which creates friction to stop the rotation of the wheels, which in turn stops the vehicle.

(17) "Brakeshoe anchor pin" means a pin which holds the brakeshoe in its proper place within the brakedrum and serves as a pivot for the brakeshoes. One end of each brakeshoe is generally connected to the backing plate or spider by anchor pins.

(18) "Brake system" means a combination of one or more brakes and the related means of operation and control.

(19) "Brake wheel cylinder" means a unit for converting hydraulic fluid pressure to mechanical force for actuation of a brake.

(20) "Contamination" means any grease, oil, or brake fluid on the brake lining, pad friction surface, or braking surface of the brake drum or rotor.

(21) "Diaphragm" means a rubber partition placed between the two halves of the brake chamber. When air pressure is introduced into the chamber on one side of the diaphragm, the pressure flexes the diaphragm and exerts force on the pushplate attached to the push rod. The pushplate is held up against the diaphragm by a light duty return spring.

(22) "Disc brake" means a brake in which the friction forces act on the faces of a disc.

(23) "Disc brake caliper assembly" means the nonrotational components of a disc brake, including its actuating mechanism for development of friction forces at the disc.

(24) "Disc (rotor)" means the parallel-faced circular rotational member of a disc brake assembly acted upon by the friction material.

(25) "Drum" means the cylindrical rotational member of a drum brake assembly acted upon by the friction material.

(26) "Drum brake" means a brake in which the friction forces act on the cylindrical surfaces of the drum.

(27) "Foot valve" means a brake application and release valve located on the floor or firewall of the motor vehicle between the throttle and the clutch. It may be either a treadle or a pedal and is operated by foot pressure applied by the driver to apply air pressure to the service brake system. The valve may be either attached to the treadle or may be remotely mounted under the floor and connected to the pedal by means of a rod. This valve generally applies air pressure to all braking axles on all vehicles in the combination.

(28) "Hydraulic brake system" means a brake system in which brake operation and control utilizes hydraulic brake fluid.

(29) "Pedal reserve" means the amount of total pedal travel left in reserve when the brake pedal is depressed to the "brake applied" position.

(30) "Push rod" means the sliding rod projecting from a brake chamber and connected to the slack adjuster by which the force of compressed air in the brake chamber is transmitted to the brakeshoes through connecting linkage during a brake application.

(31) "Safety valve" means a pressure release unit used to protect the air system against excessive pressure.

(32) "Service brake system" means the primary brake system used for slowing and stopping a vehicle.

(33) "Slack" means the sum of all clearances in the braking system and total system elasticity.

(34) "Slack adjuster" means a lever attached to the brake camshaft and connected to the brake chamber push rod. The slack adjuster provides a means of adjusting the brakes to compensate for brake lining wear.

(35) "Straight air brake system" means a mechanical type brake system actuated by air pressure in brake cylinders or brake chambers.

(36) "Supply air" means the air that is under pressure in the air supply system of a vehicle. It consists of those lines or tanks, except protected air tanks, which are under pressure when the system is fully charged and when all valves are in the normal position with the brakes unapplied.

(37) "Vacuum assisted hydraulic brake system" means a hydraulic type brake system which utilizes vacuum to assist the driver's effort to apply the brakes.

(38) "Vacuum brake reservoir" means a storage container for vacuum.

(39) "Wedge brake" means a wheel brake which uses air or hydraulic pressure to force wedges instead of cams between the brakeshoes to apply the shoes against the brakedrums. In air applied wedge brake systems, the brake actuator axis is parallel to the axle and pushes directly on the wedge in this direction instead of being mounted at right angles to push a slack adjuster and rotate a cam as in the conventional type of air brake system.

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-030, filed 1/7/14, effective 2/7/14; WSR 83-21-080 (Order 83-10-01), § 204-76-030, filed 10/19/83; WSR 80-10-006 (Order 80-07-01), § 204-76-030, filed 7/25/80.]

PDF204-76-040

Straight air brakes.

Straight air brake systems are subject to the following requirements and limitations:

(1) Supply system.

(a) The air compressor for a straight air brake system must cut in at not less than 85 pounds per square inch and must cut out at not more than 130 pounds per square inch.

(b) Air compressor buildup time must not be more than two minutes to increase the air pressure from 60 pounds per square inch to 90 pounds per square inch. Engine speed will not exceed 1500 RPM to meet this requirement.

(c) Air loss from the air system must not exceed:

(i) 3 pounds per square inch per minute for a single vehicle.

(ii) 4 pounds per square inch per minute for a two vehicle combination.

(iii) 5 pounds per square inch per minute for a three or more vehicle combination. Air losses will be measured by the air gauge in the vehicle.

(d) The air system must contain no more than one quart of contaminants. Water and oil must be considered contaminants.

(2) Brake assembly.

(a) Adjustment of all brakes must comply with the manufacturer's recommended specifications as set forth in WAC 204-76-99001, 204-76-99002, 204-76-99003, and 204-76-99004.

(b) Brake system components must meet all the requirements of RCW 46.37.360.

(i) Brake hoses and their attachments must:

(A) Meet the requirements of RCW 46.37.360; and

(B) Comply with Part 393.45 of Title 49 C.F.R.

(ii) Brake hose splices must consist of only those unions specifically manufactured for that purpose and be properly installed.

(iii) Brakedrums will not be cracked or broken to the extent that such crack or break appears on the outside of the drum.

(iv) Brake lining, pad friction surface, or braking surface of the brake drum or rotor must not be contaminated with grease, oil, or brake fluid.

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-040, filed 1/7/14, effective 2/7/14; WSR 83-21-080 (Order 83-10-01), § 204-76-040, filed 10/19/83; WSR 80-10-006 (Order 80-07-01), § 204-76-040, filed 7/25/80.]

PDF204-76-050

Air over hydraulic brakes.

Air over hydraulic brake systems are subject to the following requirements and limitations:

(1) Supply system.

(a) The air compressor for an air over hydraulic brake system must cut in at not less than 85 pounds per square inch and must cut out at not more than 105 pounds per square inch.

(b) Air compressor buildup time must not be more than one minute to increase the air pressure from 60 pounds per square inch to 90 pounds per square inch. Engine speed will not exceed 1500 RPM to meet this requirement.

(c) Air loss from the air system must not exceed:

(i) 3 pounds per square inch per minute for a single vehicle.

(ii) 4 pounds per square inch per minute for a two vehicle combination.

(iii) 5 pounds per square inch per minute for a three or more vehicle combination. Air losses will be measured by the air gauge in the vehicle.

(d) The air system must contain no more than one quart of contaminants. Water and oil must be considered contaminants.

(e) Hydraulic fluid must be maintained in excess of 50 percent of the brake master cylinder capacity.

(2) Brake assembly.

(a) Adjustment of all brakes must comply with the manufacturer's recommended specifications.

(b) Brake system components must meet all the requirements of RCW 46.37.360, and brake drums will not be cracked or broken to the extent that such crack or break appears on the outside of the drum.

(c) Brake lining, pad friction surface, or braking surface of the brake drum or rotor must not be contaminated with grease, oil, or brake fluid.

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-050, filed 1/7/14, effective 2/7/14; WSR 83-21-080 (Order 83-10-01), § 204-76-050, filed 10/19/83; WSR 80-10-006 (Order 80-07-01), § 204-76-050, filed 7/25/80.]

PDF204-76-060

Vacuum assisted hydraulic brakes.

Vacuum assisted hydraulic brake systems are subject to the following requirements and limitations:

(1) Supply system.

(a) When equipped with a protected vacuum reservoir, there must be no more than three inches drop in vacuum in one minute after turning off the engine.

(b) When not equipped with a protected vacuum reservoir, a slight drop of the brake pedal should be felt after starting the engine when moderate pressure is applied to the pedal. If a slight drop of the pedal does not occur, the vacuum system must be deemed to be defective.

(c) Hydraulic fluid must be maintained in excess of 50 percent of the brake master cylinder capacity.

(d) The hydraulic portion of the system must pass the following test procedures:

(i) With the engine off, a hard brake pedal application must be made.

(ii) Pedal pressure must be reduced but not released.

(iii) Pedal pressure must be gradually reapplied and pedal reserve must be checked.

(iv) No pedal reserve drop should occur. Any such drop in pedal reserve must cause the system to be deemed defective.

(2) Brake assembly.

(a) Adjustment of all brakes must comply with the manufacturer's recommended specifications.

(b) Brake system components must meet all the requirements of RCW 46.37.360, and brake drums will not be cracked or broken to the extent that such crack or break appears on the outside of the drum.

(c) Brake lining, pad friction surface, or braking surface of the brake drum or rotor must not be contaminated with grease, oil, or brake fluid.

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-060, filed 1/7/14, effective 2/7/14; WSR 83-21-080 (Order 83-10-01), § 204-76-060, filed 10/19/83; WSR 80-10-006 (Order 80-07-01), § 204-76-060, filed 7/25/80.]

PDF204-76-070

Hydraulic brakes.

Hydraulic brake systems are subject to the following requirements and limitations:

(1) Supply system.

(a) Hydraulic fluid must be maintained in excess of 50 percent of the brake master cylinder capacity.

(b) The hydraulic system must pass the following test procedures:

(i) With the engine off, a hard brake pedal application must be made.

(ii) Pedal pressure must be reduced but not released.

(iii) Pedal pressure must be gradually reapplied and pedal reserve must be checked.

(iv) No pedal reserve drop should occur. Any such drop in pedal reserve must cause the system to be deemed defective.

(2) Brake assembly.

(a) Adjustment of all brakes must comply with the manufacturer's recommended specifications.

(b) Brake system components must meet all the requirements of RCW 46.37.360, and brake drums will not be cracked or broken to the extent that such crack or break appears on the outside of the drum.

(c) Brake lining, pad friction surface, or braking surface of the brake drum or rotor must not be contaminated with grease, oil, or brake fluid.

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-070, filed 1/7/14, effective 2/7/14; WSR 83-21-080 (Order 83-10-01), § 204-76-070, filed 10/19/83; WSR 80-10-006 (Order 80-07-01), § 204-76-070, filed 7/25/80.]

PDF204-76-99001

Bolt type brake chamber data.

BOLT TYPE BRAKE CHAMBER DATA | |||||||

Type | Effective Area (Square Inches) | Outside Diameter | Maximum Stroke With Brakes Adjusted | Maximum Stroke At Which Brakes Must Be Readjusted | |||

A | 6 | 5 1/4 | Should be | 1 1/4 | |||

B | 9 | 6 3/16 | as short as | 1 3/8 | |||

C | 12 | 6 15/16 | possible | 1 3/8 | |||

D | 16 | 8 1/16 | without | 1 3/4 | |||

E | 24 | 9 3/16 | brakes | 1 3/4 | |||

*F | 30 | 9 7/8 | dragging | 2 | |||

G | 36 | 11 | 2 1/4 | ||||

* | Most common types. |

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-99001, filed 1/7/14, effective 2/7/14; WSR 89-12-019 (Order 89-03-ESR), § 204-76-99001, filed 5/30/89; WSR 88-01-018 (Order 87-04-ESR), § 204-76-99001, filed 12/8/87; WSR 80-10-006 (Order 80-07-01), § 204-76-99001, filed 7/25/80.]

PDF204-76-99002

Clamp type brake chamber data.

CLAMP TYPE BRAKE CHAMBER DATA | ||||||||

Type | Effective Area (Square Inches) | * Outside Diameter | Maximum Stroke With Brakes Adjusted | Maximum Stroke At Which Clamp Type Brakes Must Be Readjusted | Maximum Stroke At Which Long Stroke Clamp Type Brakes Must Be Readjusted | |||

6 | 6 | 4 1/2 | Should be | 1 1/4 | ||||

9 | 9 | 5 1/4 | as short as | 1 3/8 | ||||

12 | 12 | 5 11/16 | possible | 1 3/8 | 1 3/4 | |||

16 | 16 | 6 3/8 | without | 1 3/4 | 2 | |||

20 | 20 | 6 25/32 | brakes | 1 3/4 | 2 (2.5" rated stroke) OR 2 1/2 (3" rated stroke) | |||

24 | 24 | 7 7/32 | dragging | 1 3/4 | 2 (2.5" rated stroke) OR 2 1/2 (3" rated stroke) | |||

30 | 30 | 8 3/32 | 2 | 2 1/2 | ||||

36 | 36 | 9 | 2 1/4 | |||||

* | Dimensions listed do not include capscrew head projections for bolt clamp projections for clamp type brake chambers. |

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-99002, filed 1/7/14, effective 2/7/14; WSR 89-12-019 (Order 89-03-ESR), § 204-76-99002, filed 5/30/89; WSR 88-01-018 (Order 87-04-ESR), § 204-76-99002, filed 12/8/87; WSR 80-10-006 (Order 80-07-01), § 204-76-99002, filed 7/25/80.]

PDF204-76-99003

Push rod force vs. travel.

The following chart outlines push rod force vs. travel:

|

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-99003, filed 1/7/14, effective 2/7/14; WSR 80-10-006 (Order 80-07-01), § 204-76-99003, filed 7/25/80.]

PDF204-76-99004

Relationship of push rod and slack adjuster angle to brake force.

The following diagram shows the relationship of push rod and slack adjuster angle to brake force:

RESULT EVEN TORQUE (BRAKE INPUT) BETWEEN BRAKE ADJUSTMENTS | |

*LAST HALF OF CAM ROTATION* LEVERAGE INCREASING TO THE MAXIMUM AND BRAKE CHAMBER EFFICIENCY DECREASING WITH LENGTH OF STROKE. | *FIRST HALF OF CAM ROTATION* BRAKE CHAMBER EFFICIENCY IS MAXIMUM AND LEVERAGE IS MINIMUM AT BEGINNING OF STROKE. LEVERAGE INCREASES WITH THE INCREASED MOVEMENT. |

| |

POINT OF GREATEST LEVERAGE MOVEMENT PAST THIS POINT RESULTS IN LESS LEVERAGE, REDUCED INPUT AND LOWER BRAKE EFFICIENCY. | *FIRST HALF OF RATED TRAVEL* BRAKE CHAMBER IS AT THE MAXIMUM EFFICIENCY. |

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-99004, filed 1/7/14, effective 2/7/14; WSR 80-10-006 (Order 80-07-01), § 204-76-99004, filed 7/25/80.]

PDF204-76-99005

Air operated wedge brake adjustment.

Wedge brake shoe travel must not exceed 1/16 inch, nor shall the gap between the brake shoe lining and the brake drum exceed .06225 inch when the brake is released.

[Statutory Authority: RCW 46.37.005. WSR 14-03-018, § 204-76-99005, filed 1/7/14, effective 2/7/14; WSR 88-01-018 (Order 87-04-ESR), § 204-76-99005, filed 12/8/87.]